DONGGUAN HUAXIAN LTD. |

|

Verified Suppliers

|

|

Small 6 Pallets Mobile Vegetables Forced Air Pre Cooler For Cold Storage Room

Pre-cooling is the process of quickly removing field heat and respiratory heat from harvested fresh fruits and vegetables before transportation, storage or processing. Pre-cooling must be carried out immediately after harvesting at the place of origin. Pre-cooling is the key to successful storage of fruits and vegetables, and it is also an essential link in the cold chain circulation of fruits and vegetables. Pre-cooling slows down life activities such as respiration and transpiration of fruits and vegetables, prolongs the physiological cycle of fruits and vegetables; reduces post-harvest phenomena such as weightlessness, wilting, and yellowing; improves the ability of fruits and vegetables to resist mechanical damage, pests and physiological diseases; pre-cooling also It can reduce the cooling load of refrigerated transport vehicles and cold storage.

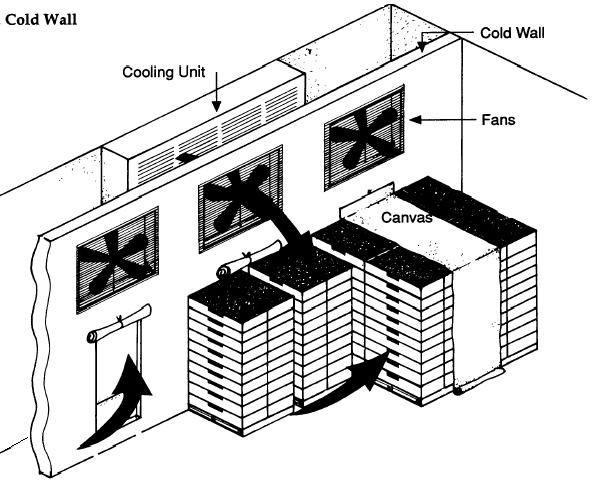

Differential pressure precooling is to use the suction effect of the fan on one side of the packing box to form a pressure difference on both sides of the packing box, forcing the cold air to flow through the surface of the fruit and vegetable according to the designed channel, taking away the heat of the fruit and vegetable and cooling the fruit and vegetable.

Pressure difference cooler is also named as force air cooler. It is

widely applied in cooling fruit, vegetable and fresh cut flowers.

The method is to force cold air flow through boxes or pallets to

realize heat exchange between cold air and products.

The principle is pressure difference at both sides of boxes and

pallets caused by ban which drive cold air come into boxes from one

side and contact with products, then come out at other side, so as

to take away heats in boxes.

Design idea:

Model

| No | Model | Power | Fan Amount | Weight |

| 1 | HXF-3T | 13.7kw | 42000m3/h | 1,880kg |

Pictures

Successful Case

Guarantee

a. All Huaxian systems delivered to customers are carefully

examined and tested, with 72 hours trouble-free trial operation;

b. All Huaxian systems delivered are plug-in ready and well piped;

c. All Huaxian systems enjoy 12 months guarantee ever since B/L

date.

FAQ

1. Can the pre-cooler be customized according to the processing capacity?

2. How can the mobile forced air cooler moved?

3. Should the pre-cooler be used in cold storage?

4. Can fruits and vegetables be stored while pre-cooling in the cold storage?

5. How can I make order?