HUATEC GROUP CORPORATION |

|

Verified Suppliers

|

|

The Brinell hardness testing creates the largest indentation

comparing all other hardness testing methods. It is able to reflect

the comprehensive features of the material, and is unaffected by

the microstructure and inhomogeneous of the specimen. So it with

high precision and widely used in industry such as metallurgy,

forging, casting, unhardened steel and nonferrous metals, as well

as in the laboratories, universities , and scientific research

institutes.

HBE-3000 Brinell Hardness Tester conforms to:

Specification:

Technical data:

Loads:3000kgf (29400N), 1500Kgf (14700N), 1000Kgf (9800N),

750Kgf(7355N),

500Kgf (4900N), 250Kgf (2452N), 187.5Kgf (1839N), 125Kgf (1226N),

100Kgf (980N), 62.5Kgf(612.9N)

Load dwell duration: 2s~99s, can be set and stored

Tungsten Carbide Ball indenter: 10mm,

Measuring range: 3.18HBW~658HBW

Magnification of the microscope: 20X

Resolution capability of the microscope: 0.005mm

Accuracy of Brinell Hardness Value:

Hardness Range(HBW) Error (%)

Repeatability(%)

≤ 125 ± 3.0 ≤3.0

125<HBW≤225 ± 2.5 ≤2.5

> 225 ±2.0 ≤2.0

Max measurable height: 230 mm

Max measurable depth: 140 mm

Dimensions: 530mm×260mm×750mm

Power supply: 220/110 V, 50/60 Hz, 4A

Weight: 120kg

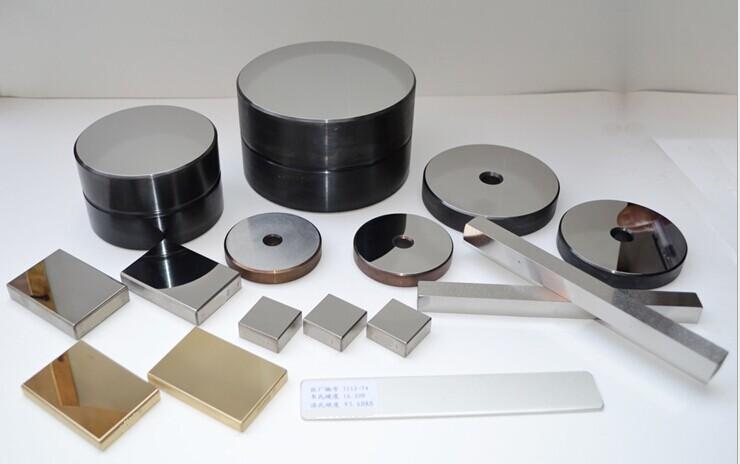

Standard blocks: 125-350HBW10/3000, 125-350HBW10/1000

Standard configuration

Host machine 1

Standard block

125-350HBW10/3000 1

Standard block

125-350HBW10/1000 1

Ф10mm Tungsten Carbide Ball indenter

1

Mounting screws for indenter 1

Screwdriver for indenter mounting

1

Flat anvil 1

“V ”shape anvil 1

20X microscope 1

Power supply wire 1

Dust cover 1

Optional accessories:

Standard blocks of other value

Ф5mm Tungsten Carbide Ball indenter

Ф2.5mm Tungsten Carbide Ball indenter

Ф10mm Tungsten Carbide Ball

Ф5mm Tungsten Carbide Ball

Ф2.5mm Tungsten Carbide Ball