Henan HTX Group Co., Ltd. |

|

Verified Suppliers

|

|

Product Description

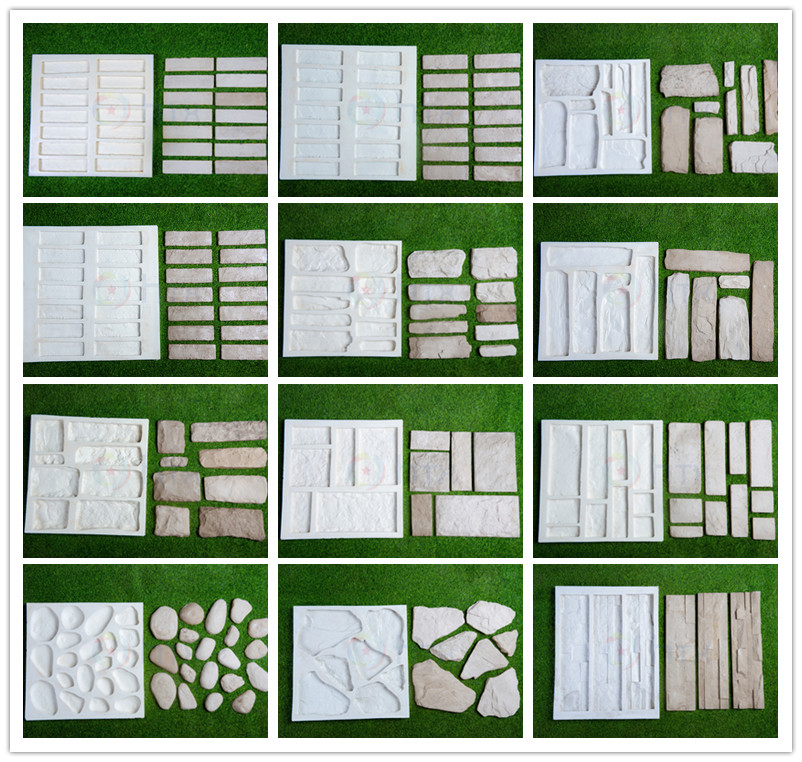

The Wet cast production line is a modular system that can start off as a simple piece of stand alone equipment which can be upgraded and added to, to create an automated production line for decorative wet cast patio slabs.The overall batching system adopts batching machine, cement silo, JS500 mixer (JS750 can be replaced if the customer needs large output), equipped with water scale, cement scale and PLC control cabinet. For example, the mobile clear equipment of the mixer can be added to the quotation at the high-end end of the system, and the batching machine can be replaced with a single warehouse and weighed separately.Wet concrete dosing system, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving, 3D Wall panel, terrazzo floor tile, etc .

Specifications

| Name | Model | Specification | Size (mm) | Power (Kw) | Capacity (m2/day) | Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Wet Cast Machinery | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

Applications

Auto Wet Conrete Dosing System Production line advantages:

1.More efficient production, can achieve 800M2 Per day(8hrs)

2.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

3.Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.

4. The auto spray painting machine, has function for mold oil sparying, stroll color painting and full color painting, also it can be turned on/off separately.

Related Products

Certificate