Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Henan manufacturer lower price high active performance metakaolin used as concrete admixture

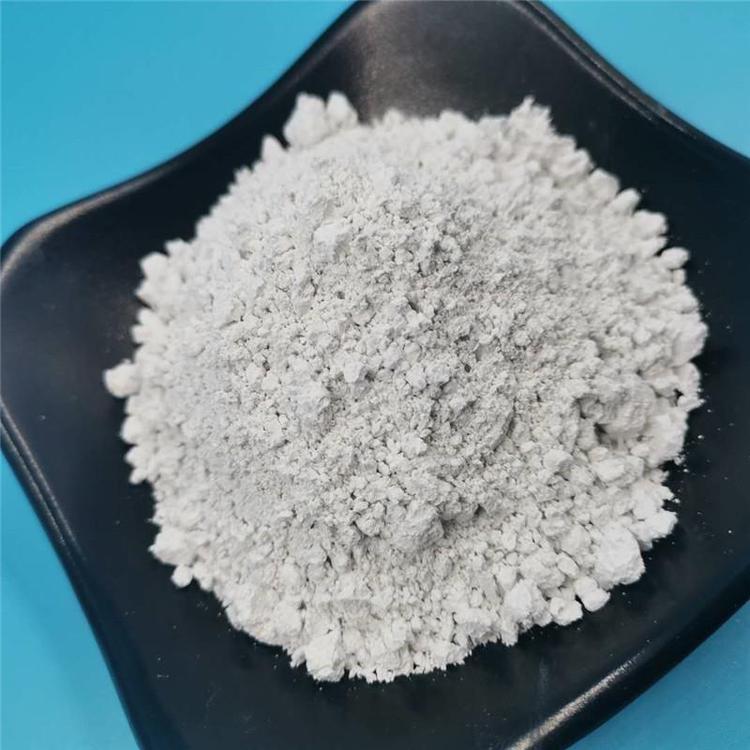

Metakaolin (MK) is anhydrous aluminum silicate (Al2O3 · 2SiO2, abbreviated as AS2) formed by dehydrating kaolin (Al2O3·2SiO2·2H2O, abbreviated as AS2H2) at an appropriate temperature (600~900 ℃). ). Kaolin belongs to the layered silicate structure, and the layers are combined by van der Waals bonds, and the OH- ions are firmly combined in it. When kaolin is heated in the air, several structural changes will occur. When heated to about 600 ℃, the layered structure of kaolin will be destroyed due to dehydration, forming a transition phase with poor crystallinity-metakaolin. Because the molecular arrangement of metakaolin is irregular, it presents a thermodynamic metastable state and has gelling properties under appropriate excitation.

Metakaolin is a kind of highly active mineral admixture. It is an

amorphous aluminum silicate formed by calcination of ultrafine

kaolin at low temperature. It has high pozzolanic activity. It is

mainly used as a concrete admixture and can also be used for

high-performance geological polymerization.

Henan manufacturer lower price high active performance metakaolin used as concrete admixture

Metakaolin chemicaland physical data:

| Item | Metakaolin |

| Size | 200mesh,325mesh,800mesh,1250mesh,1500mesh |

| Sio2 Min | 50.00% |

| Al2o3 Min | 40.00% |

| K2o | 0.10% |

| H2o | 0.10% |

| Fe2o3 | 0.30% |

| Cao | 0.10% |

| Mgo | 0.10% |

| Tio2 Max | 0.50% |

| PH | 8 |

| Whiteness | 85 |

Ingredients: Highly active metakaolin product, which is composed of amorphous aluminosilicate produced by calcining kaolin.

Product application: Highly active metakaolin superfine pozzolan can improve the strength, life and working performance of Portland cement concrete and cement products. DX-80M highly active metakaolin can be used as an additive for cast-in-place concrete (GFRC and GRC), mortar, mortar, concrete masonry and other cement products. (Strongly recommended for high-strength concrete and cement precast parts).

Product features: Effectively improve the early strength and full-age strength of cement. Effectively alleviate the aging and degradation of cement. Significantly improve the vividness of the color of cement products. It can completely replace silicon powder and part of water reducer. Prevent cement cracking, increase the permeability of cement products, and reduce water permeability. It reacts with the by-product [Ca(OH)2] produced by the reaction of cement and water, effectively increasing the physical properties of cement. Prevent or reduce the whitening of cement after curing.

Properties: white powdery crystals or scaly lustrous crystals with triclinic axis

Number of meshes: 200 325 800 1250 2000 mesh

Content: 99%

Henan manufacturer lower price high active performance metakaolin used as concrete admixture

Kaolin separation method: in order to separate non-clay minerals and organic matter such as quartz, feldspar, mica, iron minerals, titanium minerals in kaolin, to produce kaolin products that can meet the needs of various industrial fields, in addition to using gravity separation, flotation, In addition to the purification of kaolin by magnetic separation, sometimes deep processing methods such as chemical bleaching, ultra-fine peeling, calcination, and surface modification are used to treat the kaolin. The beneficiation and processing of kaolin is divided into two processes: dry method and wet method;

1. The dry method generally crushes the mined ore through a crusher to about 25mm, and feeds it into a cage crusher to reduce the particle size to about 6mm. The crushed ore is further pulverized by a blower Raymond mill equipped with a centrifugal separator and a cyclone dust collector. This process can remove most of the sand and gravel, and is suitable for processing those ore with high raw ore whiteness, low sand content and suitable particle size distribution. Dry processing has low production costs, and the products are usually used as low-cost fillers in rubber, plastics and papermaking industries;

2. The wet processing process generally crushes the raw ore, and then goes through mashing, desanding, cyclone classification, stripping, centrifuge classification, magnetic separation (or bleaching), concentration, pressure filtration, and drying. Can be used for ceramic or paper coatings. If the filler grade or papermaking coating grade kaolin is prepared, the calcination process needs to be added, that is, ore crushing, smashing, cyclone classification, peeling, centrifugal classification, concentration, pressure filtration, internal steam drying, calcination, depolymerization, etc.;

3. Calcining method: Calcining is a widely used method for producing special kaolin products. It has 4 calcination temperature ranges: 500~700℃, 925℃, 1000℃, 1400℃. Calcined at different temperatures, the application range of the products obtained is also different. Calcined kaolin with only hydroxyl groups removed is used as a filler for cable plastics and rubber seals; kaolin calcined at 1000°C can replace Tio2 and be used as a paper filler; after 1300~ Kaolin calcined at 1525℃ can be used as filler for refractory products, lining of optical glass crucible, etc.;

4. Stripping method: In order to prepare coating-grade kaolin products, the thicker laminated kaolin must be peeled into thin slices. The stripping methods include wet grinding, extrusion and chemical soaking methods:

The usage of metakaolin:

1. Used in the ceramic industry. Kaolin is mainly used as a raw material for ceramics and used to make various types of ceramics;

2. Used in refractory materials and cement industry. Mainly due to the better fire resistance of kaolin, higher grade kaolin can be used to make optical glass, glass fiber crucibles and laboratory crucibles, and lower purity kaolin can be used to make refractory materials such as refractory bricks and refractory mud;

3. Used in the papermaking industry. Kaolin is used as a filler for paper, which can greatly improve the whiteness and smoothness of paper;

4. Used in the rubber industry. Kaolin is used as a reinforcing agent and filler for rubber, which can improve the strength and acid resistance of rubber;

5. Used in the petrochemical industry. Kaolin can be made into high-efficiency adsorbent synthetic chemical molecular sieves, and can also be used as a catalyst for petroleum cracking;

6. Used in the pharmaceutical and textile industry;

7. Used in the field of national defense technology. For example: atomic reactor, jet aircraft, etc.

Henan manufacturer lower price high active performance metakaolin

used as concrete admixture

Active metakaolin Packaging

1.25 kg woven bag, 40 woven bags/tons bag.

2.25kg woven bag, 40 woven bags/pallet

3.25kg paper bag, 40 paper bags/pallet

4.25kg paper bag, 40 paper bags/carton

5.Can make the package according to customer's requirements.

Active metakaolin Shipping

1.FEDEX/DHL/UPS/TNT for samples.

2.By Sea for batch goods.

3.Customers specifying freight forwarders or negotiable shipping

methods!

4. Active metakaolin Delivery Time:

(1)Samples:3 days for common shape samples;15 days for special

shape samples.

(2)Batch goods:Within 7-10days for in stock Active metakaolin from

ordering shipping space to deliver goods and within20-30 days for

NO in stock Active metakaolin.

Payment Terms

(1)T/T, Western Union,LC;

(2)Usually 30% deposits,70% balance to be paid before delivery or

against copy of BL or negotiations

MOQ: Usually 1 container, MOQ 1Tons, Customers can order certain

weight for Active metakaolin.

Henan manufacturer lower price high active performance metakaolin

used as concrete admixture

Q1:Are you a manufacturer or trader?

A:Factory+trade(mainly factories,meanwhile,we operates other related products)

Q2:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your needs.

Q3:After an order is confirmed,when deliver?

A:15-25days after deposit; if customer sized, 35days.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary

certification.

Q6:Can you offers samples?

A:Of course, samples are free but freight paid by the buyers.

Q7: What is the service life of your bricks?

A:Depend on brick types, using conditions and methods.

Q8: Can we visit your factory?

A:Of course,welcome to visit at any time. Seeing is believing.

Q9:How to solve the quality problems?

A:If the products have quality problems, we will be responsible to offer compensation.

Hongtai Kiln Refractory has professional sales and after-sale service team who provide customers all-around service about product selection, transportation, installation and operation technology training etc. Now we have established cooperation relationship with many science and research units and our products have been sold to Vietnam, Thailand, Malaysia, South Korea, Pakistan, Kazakhstan, India, Japan, Indonesia, Germany, Italy, Mongolia, Russia, Argentina, colombia, Egypt, South Africa and etc.

We has over 20 years experience on producing high active performance

metakaolin used as concrete admixture.

Payment Guarantee: If couldn't trust us at first order, could use trade Assurance.

Jerry Li

Cell&WhatsApp: 0086-13373957739

Skype: live:.cid.b12dd76d43ac731e

Email: jerry(at)firebricks-supplies.com