Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

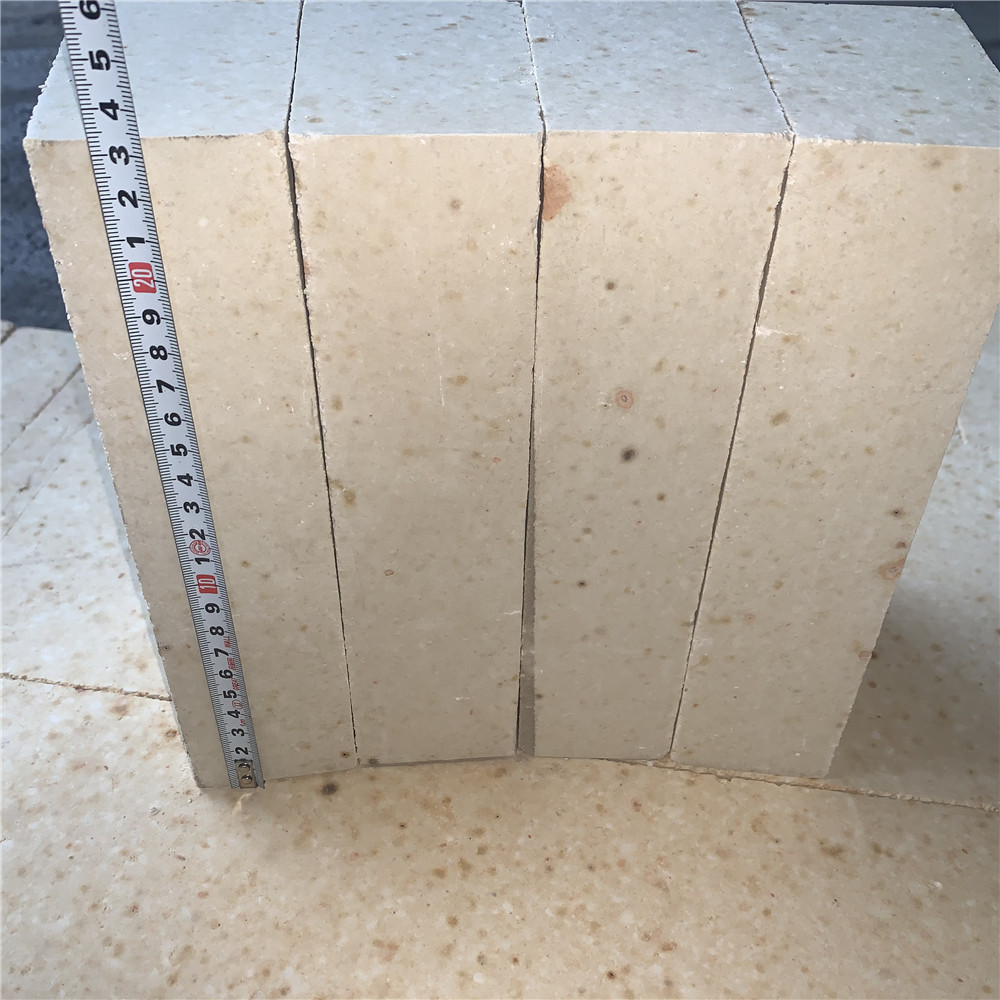

Chinese supplier high quality high alumina brick used for blast furnace

Introduction to high alumina bricks

Aluminum refractory products with aluminum

oxide (Al2O3) content higher than 48%.

A neutral refractory with an alumina content of more than 48%. It

is formed and calcined from bauxite or other raw materials with

high alumina content. High thermal stability, refractoriness above

1770℃. It has good slag resistance and is used for the lining of

steelmaking electric furnaces, glass melting furnaces, cement

rotary furnaces, etc.

High-load soft, low-creep high-alumina bricks [1] are high-grade

refractories made of super-grade bauxite, fused corundum, and fused

mullite as the main raw materials.

High alumina brick is a kind of neutral refractory material with alumina content above 48%. It is formed and calcined from alumina or other raw materials with high alumina content. High thermal stability, refractoriness above 1770℃. It has good slag resistance and is used for lining steel-making electric furnaces, glass melting furnaces, cement rotary furnaces, etc.

High alumina brick is a kind of refractory material. It is an aluminum silicate refractory product with aluminum oxide (Al2O3) content higher than 48%. The main component of this refractory brick is AL2O3

Classification of high alumina bricks

1. Classified by Al2O3 content in high alumina bricks

Class Ⅰ-Al2O3 content>75%

Class Ⅱ-Al2O3 content is 60~75%

Class Ⅲ-Al2O3 content is 48-60%.

If Al2O3 content is higher than 80%, it is called super high alumina brick

If Al2O3 content is higher than 90%, it is called corundum brick.

Chinese supplier high quality high alumina brick used for blast furnace

Characteristics of high alumina refractory brick:

1. High refractoriness.

2. Good spalling resistance and wear resistance.

3. Good corrosion resistance.

4. Good thermal shock resistance.

5. High mechanical strength.

6. High-temperature creep rate is low.

a. Refractoriness

The refractoriness of high-alumina bricks is higher than that of

clay bricks and semi-silica bricks, reaching 1750~1790℃, which

belongs to advanced refractory materials.

b, load softening temperature

Because of the high Al2O3 in high alumina products, less impurities

and less fusible glass body, the softening temperature under load

is higher than that of clay bricks, but because mullite crystals do

not form a etwork structure, the softening temperature under load

is still lower than that of silica bricks.

c. Slag resistance

There are more Al2O3 in high alumina bricks, which are close to

neutral refractory materials, and can resist the erosion of acidic

slag and alkaline slag.

Chinese supplier high quality high alumina brick used for blast furnace

Specification of High alumina bricks:

Item | High alumina refractory checker brick | ||||

International code name | SK-35 | SK-36 | SK-37 | SK-38 | SK-40 |

AL2O3 %min | 48 | 55 | 65 | 75 | 80 |

Fe2O3 %max | 2 | 2 | 2 | 2 | 2 |

Refractoriness °C, min | 1760 | 1770 | 790 | 1790 | 1820 |

Refractoriness under load (0.2MPa) °C, min | 1420 | 1450 | 1500 | 1520 | 1530 |

Linear change on reheating (1500°C, 2h)% | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 |

Apparent porosity % max | 22 | 22 | 23 | 23 | 22 |

Cold crushing strength MPa min | 35 | 40 | 45 | 50 | 55 |

Bulk Density, g/cm3 min | 2.12~2.22 | 2.25~2.4 | 2.3~2.5 | 2.4~2.6 | 2.5~2.7 |

Chinese supplier high quality high alumina brick used for blast furnace

High alumina refractory bricks are widely used in all parts of furnace lining for middle and small capacity furnace such as glass furnace, blast furnace, hot-air furnace, cement furnace,chemical furnace and other heating engineering equipment.

Packing:

Standard export wooden pallet with cardboard and PET strap.

1. Strong packing will protect the goods from any possible damage

during transit.

2. Solid packing and overall stuffing can prevent the cases from

vibration and jarring.

3. We must take necessary precaution that the packing can protect

goods from pilferage or rain.

4. We can confirm that we take every possible precaution to ensure

that our products reach our customers all over the world in prime

conditon.

Shipping:

By vessel or by train from any Chinese port, Samples can be delivered by International express.

Delivery:

15-30 days working day for large quantity. The shipment we will

arrange as soon as possible. Of course, if it is a custom products,

the shipping time will delay.

Sample:

Usually by EMS, DHL, UPS, TNT, FedEx. Anyway you like. Bulk order: Usually by sea.

Payment:

It can be through T/T, L/C at sight. The specific terms determined

according to the quantity of the goods, etc.

Your inquiry related to our product & price will be replied

within 24 hours.

Export:

Our products have been exported to many countries: Australia,

Chile, USA, Russia, UK, Indonesia, etc., good quality have be

approved by our clients.

Henan hongtai kiln refractory co., LTD. is establised in 2012,located in Xinmi City, 40 kilometers southwest of Zhengzhou City in Henan Province, close to JingGuang,Longhai railway lines, with road transport facilities.Rich resoures of Refractory materials, adequate and qualified fuel in this area, provide unique conditions for refractory production,shipping and refractory industry development.

Henan hongtai kiln refractory co., LTD. has been always adhere to the principle of "quality first, credibility first, users first, quanlity and efficiency", has won the honor of "national measurement of qualified units""service standardization standards unit",which are recognized by higher office, was rated as Henan Province Contract and Keeping Promises Company, and has passed through ISO 9001:2000 Quality Mnagement System Confirmatrion, In order to meet the needs of market developemtn, we establish a "production, learning,research"strategic partnership with High Temperature Research Institute of Henann University of Science and Tchnology,and maintain long-term technical cooperation with Luoyang refractory research Institutions, the Iron and Steel Desigh Institute, Wuhan Iron and Steel Design Istitute and other scientific research institutions.Constantly adjust the production process,update product quality,built a solid foundation for wining a higher market hornor. Besides,all staff of high and low temperature furnace desigh, installation, manufacture, commissioning capacity of the company commit to every client: According to the different needs of users, we will thank all users' care by better service,higher product quality!

Production Equipments:

Test Equipments:

The products are sold all over the country, as far as Vietnam, India, Pakistan, kazakhstan, and other southeast Asian countries and regions.