Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Please provide more information as you can, we'll try to advice you detailed solutions according the furnace!

China high alumina refractory brick factory supply SK32 SK34 fire clay brick castable mortar used in wood fire place

We are one of the main SK32 SK34 SK36 high alumina refractory brick factory in China used in wood fire place. We offer an exclusive range of refractory bricks which are of optimum quality. Our range encompasses of refractory bricks, High Alumina Low Ferric Fire Bricks etc which are highly exclusive. We offer different shapes and sizes in our High Alumina Bricks which cannot be availed through anywhere else. We use the best quality material to manufacture our refractory bricks so that there is no compromise in their quality. We offer SK36 SK37 SK38 SK40 refractory brick at quite reasonable prices and also deliver them well within the stipulated time avoiding all delays. refractory bricks are produced with selected bauxite chamotte by advanced process and strict quality control. The main mineral components are corundum and mullite phases. It features excellent high temperature mechanics and chemical corrosion resistance.

The High alumina refractory bricks produced by our company are based on the production of ordinary clay bricks, using high-quality homogenizing materials as the main raw materials, adding appropriate amounts of auxiliary materials and some additives, after fine grinding, mixing, and high-pressure molding, at an appropriate firing temperature It transforms into mullite crystal phase, and the residual product has a good mineral composition to ensure that the product has high refractoriness, dense bulk density, low porosity, excellent high-temperature creep performance and good volume stability.

The international standard refractory brick code is the model beginning with SK. Among them, the aluminum content of SK-34 corresponds to the domestic content of 48, the SK-36 corresponds to the domestic content of 55, and the content of SK-38 is 75. High alumina bricks are differentiated according to their Al2O3 content. Currently, 48%, 55%, 60%, 65%, 73%, 75%, 80%, etc. are often used.

1.Made by bauxite clinker and binder through

Crushing,Mixing,Shaping,Drying and high temperature Sintering.

2.Al2O3 content is 48%-80%,main mineral components are corundum and mullite phases.

3.Refractoriness is above 1770°C,refractoriness under load is

1420-1550°C.

4.Working temperature:1350°C -1650°C.

| Item | Clay brick | High alumina brick | ||||||

| SK-30 | SK32 | sk34 | sk35 | sk36 | sk37 | sk38 | sk40 | |

| AL2O3 % min | 30 | 35 | 38 | 45 | 55 | 65 | 70 | 82 |

| Fe2O3 % max | 2.5 | 2.5 | 2 | 2 | 2 | 2 | 2 | 2 |

| Refractoriness℃(SK) | 30 | 32 | 34 | 35 | 36 | 37 | 38 | 40 |

| Refractoriness 0.2MPa ℃ | 1250 | 1350 | 1370 | 1420 | 1450 | 1480 | 1530 | 1600 |

| Apparent Porosity(%) | 22-26 | 20-24 | 20-22 | 18-20 | 20-23 | 20-23 | 20-22 | 18-20 |

| Bulk Density(g/cm³) | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 | 2.25-2.4 | 2.3-2.5 | 2.4-2.6 | 2.5-2.7 |

| ColdCrush Strength Mpa | 20 | 25 | 30 | 40 | 45 | 50 | 60 | 70 |

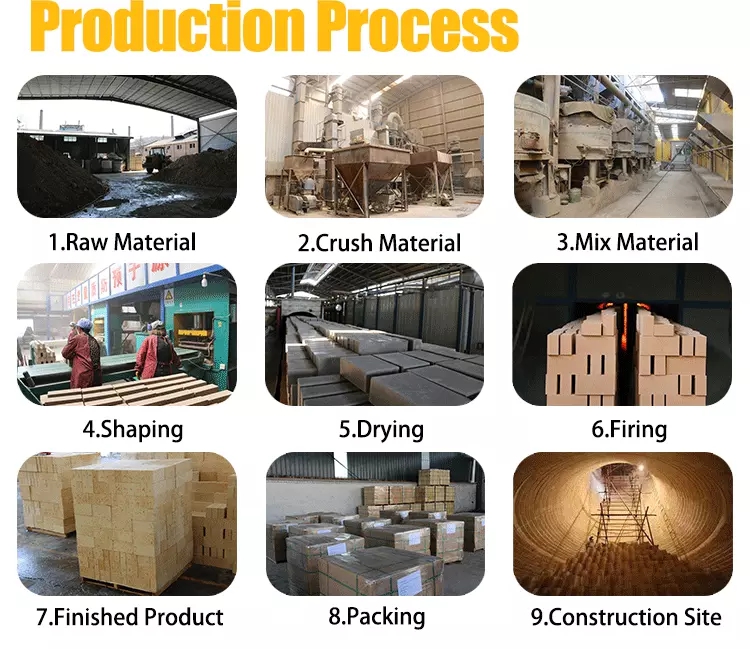

1. high alumina refractory brick Production Process

Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and

Shipment

2.sk36, sk38, sk40 high alumina brick Quality Assurance

HongTai Refractory is committed to high quality standards for all

its products and services. With its thirst on State of the art

technology at every level and a wide range of products, HongTai

Refractory can provide ideal solutions for the stringent

requirement of the customer. Backed by decade of experience in

different industries, and close association with customers,HongTai

Refractory will always bring new products which will give better

life and value to the user.

The quality assurance system consists of the following steps:

The quality assurance system consists of the following steps:

1. Inspection and Control of incoming raw materials:According to the

chemical content,raw materials are classified into different levels

to ensure quality of brick first.

2. Inspection and process control:During the production, each brick

weight twice to reduce weight error.

3. Inspection of product Standardization of quality of each product by

process control and experimentation.

4. Taking corrective measures whenever deviations are noted.

The shape and size of high alumina refractory brick:

Straight size:230×114×65 230×114×75 230×57×65

Split size: 230×114×32 230×114×40 230×114×25 230×114×50

Arch/Wedge size: 230×114×65/45 230×114×65/55 230×114×75/45 230×114×75/55 230×114×75/65

Tile size: 230×230×38 230×230×50 230×230×65 230×230×75

Other size: Key brick, Skew brick, Soap, Checker, Neck, Taper

Also produce bricks arrording to customers' needs

Usage for high alumina brick:

Iron & steel making industry: Blast furnace,hot blast furnace(stove),pellet shaft furnace,hot metal ladle,steel ladle,tundish,eating furnace,soaking pit furnace,heat treatment furnace,refining furnace,reheating furnace,metal mixter furnace,cupola furnace etc thermal technology equipment

Non-ferrous Metal industry: Smelting furnace, reverberatory furnace etc

Building materials industry: Cement kiln,glass kiln,ceramic kiln,lime kins,kiln car,tunnel kiln,rotary kiln

Energy&Incineration: Coke oven,general boiler,power generation boiler,circulating fluidized bed boiler,electric furnace,carbon roasting furnace,waste incinerators

Others: Petrochemical industry furnace,Pizza oven

Henan Hongtai Kiln Refractory Co., Ltd. is established in 2012 and located in Xinmi city, 40 kilometers southwest of Zhengzhou city. Rich resources of refractory materials, adequate and qualified fuel in this area, provide unique conditions for refractory production.

Main products are high alumina brick, clay brick, silica brick, magnesia brick, fused zirconium corundum brick, fireproof ball lightweight insulation brick, wear-resistant pouring material, corundum pouring material, low cement highigh alu strength pouring material, impermeable material, self-flowing material, plastic material, and various types of refractory materials.The company insists on "product quality is the life, enterprise integrity is the foundation", in the fierce market competition, won many users' trust and praise.The products are sold all over the world, as far as Vietnam, India, South Korea, Pakistan, kazakhstan, Malaysia and other southeast Asian countries and regions.

Quality first, reputation first, customer first is our aim;Scientific management, strong technical force, perfect testing means, advanced technological equipment and stable product quality are the guarantee of quality service.Henan hongtai kiln refractories co., LTD sincerely hopes to cooperate with you hand in hand and in good faith.

Packing for high alumina refractory brick

1.Pallet+Paper or Steel angle bead+Paper board +Plastic or Steel belt +Plastic film

(1)Wooden pallet size:Usually0.92*0.92m(standard brick),but 1*1m (special shape brick) at most,

(2)Load weight of each pallet:Usually 1.5-1.7Tons, max 2.0 Tons.

(3)20 Foot Container can be loaded max 25-26Tons, about 13-16Pallets.

2.Can make the package according to customer's requirements.

Shipping for high alumina refractory brick

1.FEDEX/DHL/UPS/TNT for samples.

2.By Sea for batch goods.

3.Customers specifying freight forwarders or negotiable shipping methods!

4.Delivery Time:

(1)Samples:3 days for common shape samples;15 days for special shape samples.

(2)Batch goods:Within 7-10days for in stock bricks from ordering shipping space to deliver goods and within20-30 days for NO in stock bricks.

Payment Terms

(1)T/T, Western Union,LC;

(2)Usually 30% deposits,70% balance to be paid before delivery or against copy of BL or negotiations

Others

1. MOQ: Usually 1 container, MOQ 1Tons, Customers can order certain PCS for special brick.

2. Quality Warranty: 2 years

1. Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractorys

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system

certification and SGS certification. And the annual supply of

shaped and unshaped refractory product is 28, 800-35, 000 tons.

3. Export experiences:

Now we have gained a global sales network reaching Taiwan, Russia,

South Korea, Vietnam, Pakistan, Bulgaria, French, India, Congo,

Angola, South Africa, and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated

or semi- automated. Such modern facilities and equipments have

provided the fine technical guarantee for the production and

testing.

5. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester Bulk Density Tester The Pressure Tester Refractoriness Tester

Jerry Li

Cell&WhatsApp: 0086-13373957739

Email: jerry(at)ht-refractory.com