East Sun New Material Technology (Shenzhen) Co., Ltd. |

|

Verified Suppliers

|

|

DTF Printer 1KG/BAG TPU Polyurethane Heat Transfer DTF Adhesive

Powder

Adhesive Powder Transparency: DTF TPU hot melt adhesive powder is

available in both transparent and colored options. Transparent

adhesive powders are commonly used when the design requires the

fabric color to show through, allowing for more vibrant and

accurate color reproduction. Colored adhesive powders, on the other

hand, can be used to create unique effects or to match specific

design elements.

Adhesive Powder Thickness: The thickness of the adhesive layer

created by the DTF TPU hot melt adhesive powder can be controlled

by adjusting the amount of powder applied during the printing

process. A thicker layer generally provides stronger adhesion, but

it may also affect the flexibility and drape of the fabric. It's

important to find the right balance between adhesion strength and

fabric properties for the desired application.

Compatibility with Different Fabrics: DTF TPU hot melt adhesive

powder is compatible with a wide range of fabric types, including

cotton, polyester, nylon, blends, and more. However, it's essential

to test the compatibility and adhesion strength on specific fabrics

before full-scale production. Some fabrics may require adjustments

in the application technique or temperature to ensure optimal

adhesion and durability.

Environmental Considerations: Some manufacturers offer DTF TPU hot

melt adhesive powders that are environmentally friendly. These

powders may have reduced VOC emissions or be formulated with

sustainable materials. Choosing environmentally friendly options

can align with sustainability goals and reduce the environmental

impact of the printing process.

Safety Precautions: When working with DTF TPU hot melt adhesive

powder, it's important to follow safety precautions recommended by

the manufacturer. This may include wearing protective equipment,

ensuring proper ventilation in the workspace, and handling the

powder in a controlled manner to minimize the risk of inhalation or

skin contact.

Customization and Effects: DTF TPU hot melt adhesive powder can be

used creatively to achieve various effects and designs. It can be

applied selectively to create textured or raised areas in the

transferred design. Additionally, multiple layers of adhesive

powder can be applied to create a thicker adhesive layer, resulting

in a more pronounced and dimensional effect.

DTF Powder For DTF Product Description

| Property | Criterion |

| Appearance | White powder |

| Composition | TPU |

| Density | 1.20±0.02 g/cm³ |

| Melt Point | 95-115 ℃ |

| Melt Index | 30±7 g/10min |

| Powder size range | 0-80 μm |

80-200 μm | |

150-250 μm |

DTF Powder For DTF Technical Parameters:

| Bonding parameters (for reference only) | Temperature | 110-130℃ |

| Press | 1.5-2.5 kg/cm2 | |

| Time | 8-15 S | |

| Washing Resistance | 40℃ | Excellent |

| 60℃ | General | |

| 90℃ | / |

DTF powder Packaging and Storage Conditions:

| Packaging | 20KG / bag, packed in PE inner bag+kraft bag |

| Storage Conditions | Stored in dry unopened packaging at room temperature for 12 months. High temperature and pressure will cause agglomeration. The trays cannot be double-pressed. |

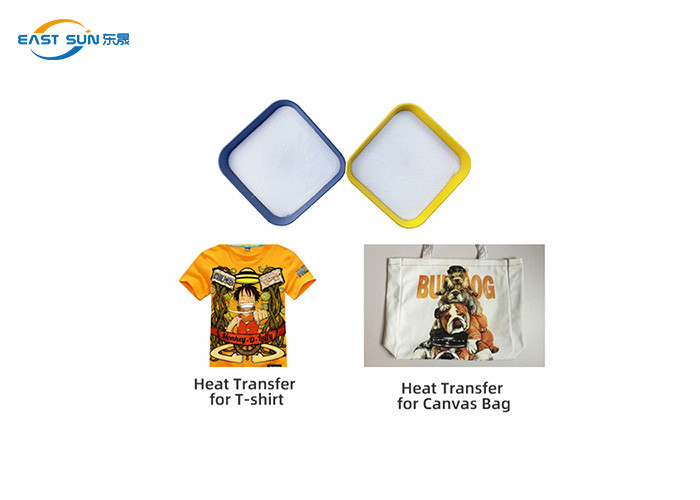

Application of DTF Powder

Printing the Design: Once the design is ready, it is printed onto a

DTF film roll using a compatible printing technique, such as screen

printing or digital printing. The ink used in the printing process

should be compatible with the DTF TPU hot melt adhesive powder.

Application of Adhesive Powder: After the design is printed, the

DTF TPU hot melt adhesive powder is applied to the desired areas of

the printed design. This is typically done using a specialized

printing equipment or process that allows for controlled and

precise application of the adhesive powder. The powder adheres to

the ink on the DTF film, creating a layer of adhesive.

Activation: Once the adhesive powder is applied, the printed DTF

film is ready for transfer onto the fabric. The DTF film is placed

on top of the fabric, with the adhesive powder facing the fabric.

Heat and pressure are then applied using a heat press machine or

similar equipment. The heat activates the adhesive powder, causing

it to melt and bond with the fabric fibers.

Cooling and Peeling: After the transfer process, the fabric, along

with the DTF film, is allowed to cool down. Once cooled, the DTF

film is carefully peeled off, leaving the transferred design bonded

to the fabric. The adhesive creates a strong bond between the

design and the fabric, ensuring good washability and durability.

Characteristics of hot melt adhesive powder

1.100% ink absorption rate,

2. The powder is clean,

3. The pattern is bright in color,

4. Very soft to the touch.

5. Second on-site delivery.

Why choose us

1. own factory, efficient technical equipment, several production

lines

2. excellent service and short delivery times

3. we are an environmentally friendly adhesive company, to ensure

the environmental performance of raw materials

4. professional R&D team, a new type of enterprise integrating

production, R&D and sales

FAQ

Q1) . How about your conventional package and the MOQ of your

adhesive powder?

We have 1kg,2kg,5kg and 20kg per bag,MOQ is 20kg.

Q2) . What type of hot melt adhesive powder do you have?

We have PA, TPU, EVA and PES hot melt adhesive powder.We can accord

your application to give your suitable type.

Q3). What is your Particle size?

0-80um, 80-200um , 150um-250um ,200um-400um

Q4). Do you provide free sample? And how many days it will take?

Yes, we can provide 0.3kg free sample, only need you to pay the

shipping cost. We will make the sample within 1- 2working days

and it will take 3-7days on the transportation.