Jiangsu Shengman Drying Equipment Engineering Co., Ltd |

|

Verified Suppliers

|

|

Foodstuff / Agriculture Industry Harrow Type Vacuum Rake Dryer Equipment

Product Description:

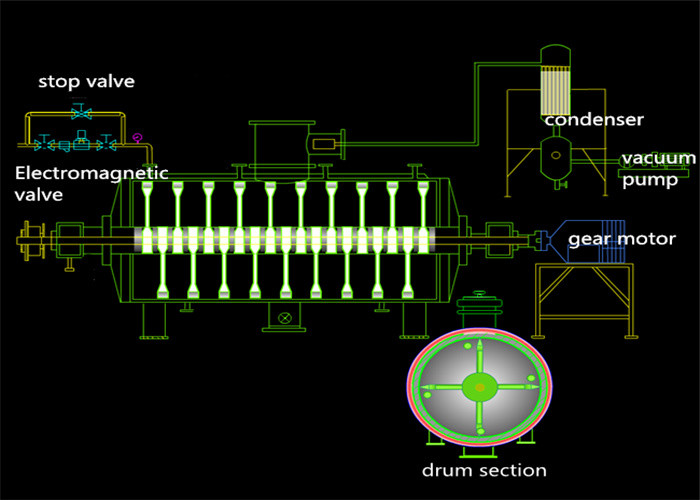

The dryer is a machine used to heat treat powders, granulates, filter cakes and pasty products in a full-continuous process.

These processes vary from drying, cooling, crystallizing and calcimining to melting, evaporating, solvents, sterilizing, etc

The paddle dryer has a heated through containing rotating heated paddle shafts. The product is fed into the front of the machine. The through is oriented at a small angle of inclination, placed slightly in unloading position. The product moves to the outlet as a result of gravity. The paddles do not have a transport function.

They are designed for maximum heat transfer. At the outlet side, the product moves out of the machine via the overflow unit.

Introduce:

Hollow blade type dryer is a predominantly conduction horizontal

mixing type dryer, Hollow blade built-in equipment.

Pour hot air or heat conduction oil into the hollow blade, make

through mixing material contact with hollow blade fully, has

reached the effect of drying materials.

Technical parameters

| Item | ZKG-500 | ZKG-1000 | ZKG-3000 | ZKG-6000 |

| Working volume ( L) | 300 | 600 | 1800 | 16.5 |

| Heating area (㎡) | 3.2 | 5.1 | 10.6 | |

| Stirring revolution (rmp) | 8-18 | |||

| Power (kw) | 4 | 5.5 | 11 | 22 |

| Design Pressure of Jacket ( mpa) | 0.3 | |||

Pressure in the cylinder (mpa) | -0.096-0.15 | |||

Note: The above data is for reference only. If having special

requirements, the factory can provide the service of consultation

and design.

Applications

Working:

The dried material is added from the middle of the shell. Under the stirring of the rotating rake teeth, the surface of the

Sale service:

(1). Ensure product with high quality and pre-commissioning before

delivery. (2). Delivery on time. (3). Provide full set of documents as customer’s requirements.

After-sale service:

Provide considerate services to minimize clients’ worries.

1. Assist clients to prepare for the first construction scheme.

2. Install and debug the equipment.

3. Train the first-line operators.

4. Examine the equipment.

5. Take initiative to eliminate the troubles rapidly.

6. Provide technical support.

7. Establish long-term and friendly relationship.

Service commitment:

1. Provide clients one-year warranty to make sure the machine work

well.

2. We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely.

3. Send every client a preferential quotation.