Jiangsu Shengman Drying Equipment Engineering Co., Ltd |

|

Verified Suppliers

|

|

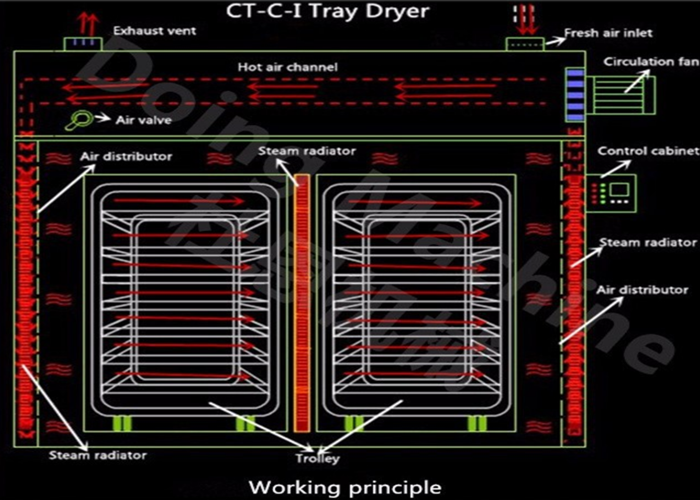

Hot sale CT-C hot air oven trans former air wave oven for ceramics oven

Introduction

CT-C series oven is our factory initiate product of our country, was upgraded and regenerated for several times and has reached to advanced level both at China and all over the world. The CT series is the first generation product, average heat efficiency about 30%, adapt centrifugal fan, box body out circle, handwork control temperature way. Through many times reformation, form the CT-C series oven, the series all adopt axes flow fan, match with auto constant temperature control system, and have computer control system for choice. The heat efficiency reach about 70% , it use seam or electric heater as heating source, use axial fan, heat exchanger to heat air in convective way. The laminar flow of hot air passes through the baking trays and will carry out heat transmission with material. Fresh air will enter into the oven from inlet to supply and then discharge from damp outlet. Fresh air is supplied, wet and

hot air is discharged continuously. In this way, suitable RH in saves energy source, which makes thermal efficiency of oven raise from 3-8% of traditional drying oven to about 35-50%. Before application, customer can adjust fan blade in order to make the temperature difference at the best state.

Feature:

Heating source: Vapor, Heat conductive oil, hot water, electric heating pipe, FRI etc.

Operation temperature: Vapor heating ambient temperature ~140℃, Max 150 ℃.

Electric, FRI, ambient temperature~350 ℃.

Auto-control system and computer control system as option.

Common vapor pressure 0.2~0.8MPa.

Electro-heating (type 1)15kw.

Special requirements should be indicated while ordering.

No standard baker can be produced based on process parameter.

Operation ambient temperature exceed 140 ℃ or less than 60 ℃ should be marked out while ordering.

Bake vehicle and tray's dimension are standard, changeable.

Bake tray dimension:460×640×45mm

Technical parameters

| type | batch drying capacity (kg) | power of fan | steam to be consumed (kg/h) | drying trolly (set) | baking trays | overall dimension mm |

| GMP-0 | 35 | 0.45 | 8 | / | 16 | 1130*1100*1750 |

| GMP-I | 120 | 0.45 | 18 | 2 | 48 | 2300*1200*2000 |

| GMP-II | 240 | 0.9 | 36 | 4 | 96 | 2300*2200*2000 |

| GMP-III | 360 | 1.35 | 54 | 6 | 144 | 3430*2200*2000 |

| GMP-IV | 480 | 1.8 | 72 | 8 | 192 | 4460*2200*2290 |

Note: The above data is for reference only. If having special

requirements, the factory can provide the service of consultation

and design.

APPLICATION

The drying oven is suitable for drying and dehydration of material and product for pharmaceutical, chemical, food, agricultural, aquatic, light industry, heavy industry; such as medicine raw material, medicine, Chinese herbal medicine, extractum, granules, powder, pill, packing bottle, pigment and dyes, dehydrated vegetables, dried fruit, sausages, plastic, resin, electric elements, varnish, and etc.

Pre-service:

As a good and rich experience supplier, we should offer customer

the best quality and best price of the machine.

1. Introduce the suitable product to the customer in detail, answer

the question raised by customer carefully.

2. Make the suitabe project as the customer requirement and make

sure the machine is suitable for the material.

Sale service:

(1). Ensure product with high quality and pre-commissioning before

delivery. (2). Delivery on time. (3). Provide full set of documents as customer’s requirements.

After-sale service:

Provide considerate services to minimize clients’ worries.

1. Assist clients to prepare for the first construction scheme.

2. Install and debug the equipment.

3. Train the first-line operators.

4. Examine the equipment.

5. Take initiative to eliminate the troubles rapidly.

6. Provide technical support.

7. Establish long-term and friendly relationship.

Service commitment:

1. Provide clients one-year warranty to make sure the machine work

well.

2. We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely.

3. Send every client a preferential quotation.