Active Member

|

[China]

Address: No.106, north changjiang road, new district, wuxi china

Contact name:Jayson

Wuxi YBT Machinery Equipment Co.,Ltd. |

|

Automatic Hydraulic High Speed CR GI SS Metal Slitting Machine

Slitting Line Machine is used for the metal plate decoiling, slitting and winding into several volumes needed width coil plate. It can be widely used in cold or hot rolling carbon steel, tinplate, stainless steel and all the other kinds of metal materials.

Input coil parameter

Processing Thickness | 0.5~4.5mm |

Processing Width | 500-1600mm |

Slitting Accuracy | ±0.15 mm |

Slitting Speed | 120m/min |

Coil Inner Diameter | 508/610 mm |

Coil Outer Diameter | ≤2000 mm |

Max. Slitting Numbers | 6-22pcs |

Slitting Coil Width | ≥20 mm |

…… | …… |

Not limited to these parameters, custom made according to client

practical demands. | |

Finished product parameter:

Width accuracy: Width>300mm, 0.5~1.5mm ±0.05mm

1.6~3.0mm ±0.10mm

Straightness (bending) Width>300mm, ≤0.35mm/1000mm

(If the two side strips are within 100mm of the mother material, considering as the common production process)

Burr :Thickness ≤1.0mm,burr≤0.03mm (Sharp blade, reasonable gap)

Thickness >1.0mm,burr ≤3% of material(Sharp blade, reasonable gap)

Scrape width range :2~25mm(Not less than 1.5 times the thickness)

Machine parameters:

| 1. | Guiding speed | : | 0~10m/min(adjustable) | ||

| 2. | Line speed | : | 0~150m/min(adjustable) | ||

| 3. | Slitting way | : | Drive shear | ||

| 4. | Recoiling way | : | Roll-up style | ||

| 5. | Operation height | : | +1000mm | ||

| 6. | Machine size | 28m X 10m | |||

| 7. | Running direction | : | The operator operates on the side of line, running from left to right | ||

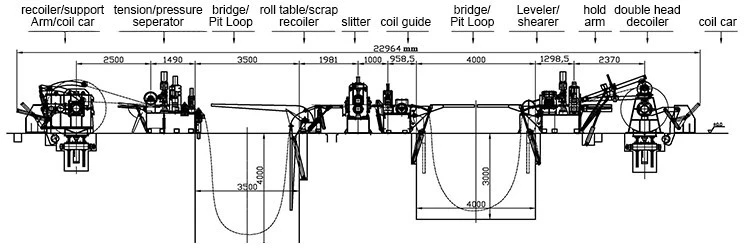

Simple working chart

Hydraulic entry coil car,Hydraulic decoiler,Leveling machine,Loop,Side guide device,Servo precision straightening machine,Cutter,Transportation table,Hydraulic lifting table,Pneumatic stacker device,Exit coil car,Pneumatic system,Hydraulic system,Electrical system

Component

Loading cart:Load coil to uncoiler,Uncoiler:Uncoil steel coils,

Leveling machine:Leveling sheet and transmit sheet to devices behind it.

Shearing machine:shearing coil end.

Horizontal accumulator:Store a amount of sheet to ensure machine working continuously.

Centering device:center sheet before slitting.

Other instructions: training and maintenance

In order to your more efficiency for production, when the machine

has arrived at the importer’ s port.

Our company will send engineers to installing the machine and

responsible for training the worker of customer until they can

operating the machine skillful.

During the warranty time, if the device can 't work normally, after

receiving your notice, within 24 hours, we will send

engineers to your factory for processing; If it is artificial

damage,then need to charge a cost.

Each machine leaving the factory will be along with related English

instructions including maintenance manual and operation manual.