Wuxi YBT Machinery Equipment Co.,Ltd. |

|

Roof Tile Rock Wood / PU Sandwich Panel Roll Forming Machine

The PU sandwich panel produced by us is good for moistureproof capacity, insect-resistance,uninflammability and sound insulation, and light weight. Besides, it is never out of shape whether in dry or wet conditions. The rigid polyurethane foam has been recognized as the best building thermal insulation material by international world today. It has low heat conductivity, and high bending resistance capacity. This rigid polyurethane foam doesn’t absorb water or decay, and it cannot be damaged by insects and mice. It has good fire resistance, and large scope of heat resistance. With the physical properties of polyurethane PU and our unique prescription, we combine high temperature polyurethane with coating steel panel, thus compact forming is achieved.It has good heat preservation capacity. This machine can be nailed as well as sawn, which makes construction easy and convenient. This equipment is widely used for steel structure workshop, roofs of simple and easy movable houses, wall body, suspended ceilings of air purification room, and separation.

Reference Work Flow:

Decoiling -- roll forming -- PU injecting -- Belt conveyer -- Fly cutting -- product run out

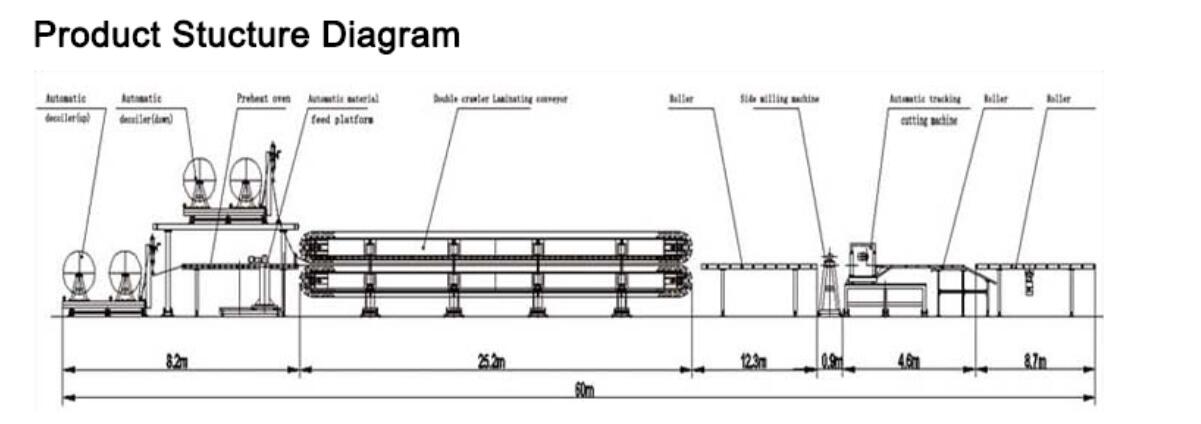

The PU panel forming machine mainly includes decoiler, feeding machine, film-covering installation machine, roll forming machine, PU foaming machine & injecting machine PU, laminator, automatic tracking cutter, and PLC control cabinet, etc.

| Machine Compositions | Unit | Quantity |

| Decoiler | set | 2 |

| Roll Forming Machine | set | 2 |

| PU Foaming&Injecting Machine | set | 1 |

| Belt Conveyer | set | 1 |

| Automatic Tracking Cutter | set | 1 |

| Control Cabinet | set | 1 |

| Product Table | set | 1 |

General Main Specifications:

Thickness of finished product

| 30-200mm |

| PU foam density | PU foam density 40±5 kg/m³ ( or depend on requrement ) |

Panel width

| 1000mm ( or denpend on customer's requirement ) |

Thickness of sheet

| 0.4-0.8mm |

Surface material

| GI/PPGI panel, Aluminum foil or PVC |