Henan Super Machinery Equipment Co.,Ltd |

|

Verified Suppliers

|

|

A. Overview for Electric MoSi2 Heating Element:

1. Electric Heating Rod is a kind of resistance heating element basically made of high pure Molybdenum Disilicide.

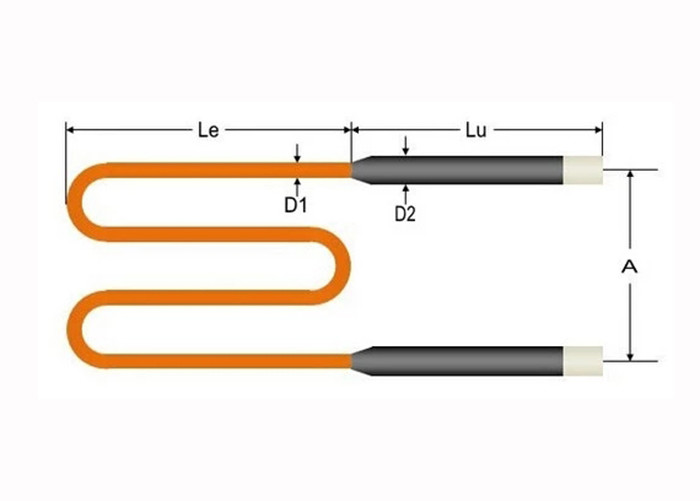

2. Shape: W Type

3. Max Temperature: up to 1800℃(under Oxidizing atmosphere) ,Applicable Temperature: 500-1700℃

4. Application: sintering and heating treating of ceramic, magnet, glass, metallurgy, refractory, ect.

Mosi2 heating element is a kind of resistance heating element with high temperature resistance, oxidation resistance and low aging based on molybdenum disilicide.When used in high temperature oxidation atmosphere, a layer of bright and compact quartz (SiO2) glass film is formed on the surface, which can protect the inner layer of si-mo rod from oxidation, so the element of si-mo rod has unique high temperature oxidation resistance.

B. Physical property of electric MoSi2 heating element:

| Volume Density | Bending Strength | Vickers Hardness | Porosity | Water absorption | Heating Elongation Rate |

| 5.5g/cm³ | 15-25kg/cm² | (HV)570kg/mm² | 7.4% | 1.2% | 4% |

C. Operation temperature of MoSi2 rod heating element in different atmosphere

| Atmosphere | 1700 Type | 1800 Type |

| Air | 1700℃ | 1800℃ |

| N2 | 1600℃ | 1700℃ |

| He | 1600℃ | 1700℃ |

| -80°C Dry H2 | 1150℃ | 1150℃ |

| -20°C Wet H2 | 1450℃ | 1450℃ |

| 10%CO2, 50%CO, 15%H2 | 1600℃ | 1700℃ |

| 40%CO2, 20%CO | 1400℃ | 1450℃ |

| Cracked and Partially Burnt Ammnia | 1400℃ | 1450℃ |

Molybdenum Disilicide MoSi2 Heating Element use and maintenance:

1. MoSi2 heating element belong to Metal ceramic material. They are hard, crisp and low impact strength at room temperature .Therefore to be careful to avoid damage during transport and installation.

2. When MoSi2 heater continuously operate in an oxidation atmosphere, the surface temperature of 1700 type should not exceed 1700 ° C,1800-type should not over 1800 ℃ and for intermittent use,1700 type-element should not over 1650 ° C,1800type-element cannot exceed 1750 ℃.

Furnace dryness

New or old furnace not used for a long time needs to be dried before using. Generally, the drying temperature is 100-200℃.

However, if the element is used for a long time under the low temperature, it will cause the low-temperature oxidation.

For little furnace, the drying time is short, the influence of several drying hours is little, but for large furnace, which need to be dried for a long time, you had better open the furnace door to ventilate well. you can open the furnace door ajar with the temperature increment and completely close until the temperature reach 1000℃ above.

Furnace start

If the furnace dry out has been completed or does not need drying, it has to rise its temperature. In order to avoid the oversized electric current impact and cause the electrical equipment overload;

Please go up the furnace temperature according to the following table.

Please tell us the following data of molybdenum disilicide MoSi2 rod heating element when send enquiry to us :

d = the diameter of hot zone ?

c = the diameter of cold zone ?

Le = the length of hot zone ?

Lu = the length of cold zone ?

a=Shank spacing?

How many pcs ?