Changzhou Hetai Motor And Electric Appliance Co., Ltd. |

|

Verified Suppliers

|

|

ES40 50W Closed-loop control high Accuracy 0.16 Nm 310V DC micro servo motor

| Model ES 40 -310V (No Brake) | |||||||

| Rated Power | Max radial force | Max axial force | Weight | Shaft type | Shaft diameter | Feedback device | No of poles |

| 50W | 120N | 60N | 0.5kg | Key shaft | φ8 | 24 bit | 10 poles |

| 100W | 120N | 60N | 0.5kg | Key shaft | φ8 | 17 bit | 8 poles |

Electrical Specification

Rated Power | Rated Speed | Voltage | Rated Current | Rated Torque | Peak Torque | Back EMF Constant |

(W) | (RPM) | (V) | (A) | (N.m) | (N.m) | (N.m/A) |

50 | 3000 | 310 | 0.56 | 0.16 | 0.48 | 16 |

Without Brake

| PIN | FUNCTION | COLOUR |

| 1 | U | Red |

| 2 | V | White |

| 3 | W | Black |

| 4 | G | Yellow/Green |

| PIN | FUNCTION | COLOUR |

| 1 | NC | |

| 2 | SD | Blue |

| 3 | SD- | Purple |

| 4 | Vcc | White |

| 5 | GND | Black |

| 6 | Shield | |

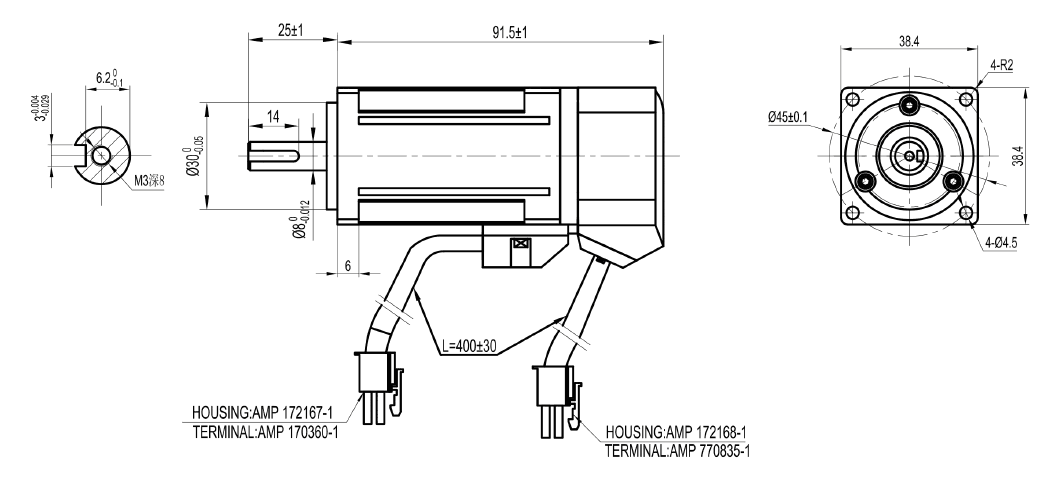

Type | 40 | ||

Power | 50W | 100W | |

Encoder | |||

L | A |

| 91.5 |

B |

|

| |

L |

| 97 | |

N | 65 | 85 | |

Type | 40 | ||

Power | 50W | 100W | |

Encoder | |||

Weight | A |

| 0.48 |

B |

|

| |

L |

| 0.52 | |

N | 0.34 | 0.45 | |

Note: A, B, L, N refers to the different encoder.

A= tamagawa single-turn absolute value 17-bit encoder

B=incremental 2500ppr optical encoder

L=tamagawa multi-turn absolute value 17-bit encoder

N=Nikon multi-turn absolute value 24 bit

Semi-finished Products

Differences between Stepper Motor and Servo Motor:

Stepper Motors have a large number of poles, magnetic pairs generated by a permanent magnet, or an electric current. Servo motors have very few poles; each pole offers a natural stopping point for the motor shaft.

The torque of a stepper motor at low speeds is greater than a servo motor of the same size.

Stepper motor operation is synchronized by command pulse signals output from the pulse generator. In contrast, the servomotor operation lags behind the command pulses.

Now you have an idea about the working of servo meter if you have any queries on this topic or the electrical and electronics projects leave the comments below.