Shenzhen Herolaser Equipment Co., Ltd. |

|

Verified Suppliers

|

|

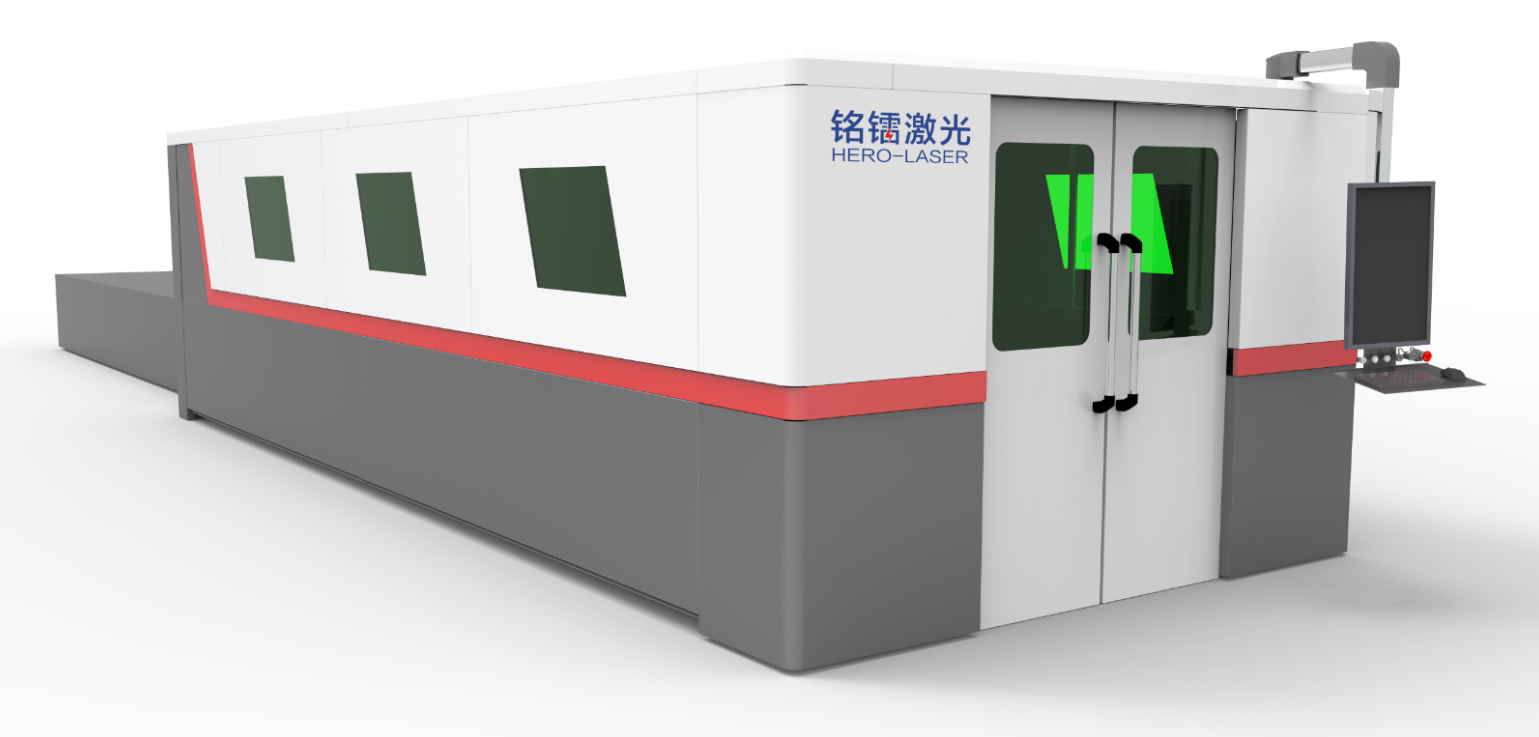

Intelligent 12000W High Power Laser Cutting Machine for Stainless Steel Sheet Metal

Introduction:

ML-CF-6025FB series laser cutter is a fiber laser cutting machine with advanced structure design and excellent machine tool performance, which applies the world-class CNC and fiber laser. It adopts gantry-type double-drive structure ,integral welded base and rack so that vibration aging treatment is carried out to eliminate the stress during welding and processing after rough machining ;and pinion transmission structure with fast speed, high precision, one-time cutting and forming without subsequent processing.

Greatly improve the processing efficiency, the layout is visible, the cutting is tight to save material. Advanced technology can increase the progress of your company's new product development and recover your equipment investment cost soon.

It is widely used in sheet metal processing, advertising sign production, mechanical parts, kitchen utensils, metal crafts, saw blades, hardware and other industries; also be used for cutting carbon steel, stainless steel, aluminum alloy, carbon steel, copper and other metals.

Features and advantages:

1. Intelligent processing.

It can automatically use standard measuring instruments, edge finding, processing and platform exchange functions after enter the plates thickness and material in the system, eliminating the repetitive operation of batch platess cutting, reducing labor intensity and improving processing efficiency.

2. Zero second perforation

3. Small hole cutting, reaching the limit of plates thickness

The field of laser cutting always been considered that the thickness of the plates is the minimum diameter of the cut hole, and the S series achieves a minimum hole diameter of 0.2 times or less than the thickness of the sheet.

4. Perfect sharp corner cutting technology

the smallest aperture ≤ 0.2 times the plates thickness of sharp corner cutting products

The perfect sharp corner cutting process is a new process developed for high-quality cutting of carbon steel thick platess. Compared with the previous standard cutting process, the new process has a faster cutting speed and a smaller section slope (35mm carbon steel 15 wires/unilateral).

5. Double Exchange platform

High and low switching table, complete a switching time ≦20 seconds, greatly improve the processing efficiency, save labor costs.

6. Automatic location and edge search function

The system has automatic positioning and edge finding function, which makes the feeding more random, faster and faster

Technical data:

| No. | Name | Parameter |

| 1 | Device model | ML-CF-6025FB |

| 2 | Laser wavelength | 1070nm |

| 3 | Laser output power | 12000W |

| 4 | Effective cutting range | 6000mm*2500mm |

| 5 | Cutting thickness (related to laser power) | Carbon steel≤35mm ;stainless steel≤25mm;Aluminum Alloy≤18mm;brass≤12mm; |

| 6 | Positioning accuracy | ±0.04mm/m |

| 7 | Repeatable positioning accuracy | ±0.02mm/m |

| 8 | Max. running speed | 100m/min |

| 9 | Max. accelerated speed | 1.2G |

| 10 | Machine tool bearing | 4 tons |

| 11 | Demand for electricity | AC380V±5%/50Hz |

| 12 | Whole machine power consumption | 160KW |

| 13 | Machine size | 15000*3700*2200mm (length*width*high) |

| 14 | Weight | About 17 tons |

| 15 | Support for graphic formats | plt/dxf,etc |

Application:

Widely used in sheet metal processing, advertising signs, mechanical parts, kitchenware, metal crafts, saw blades, hardware and other industries.

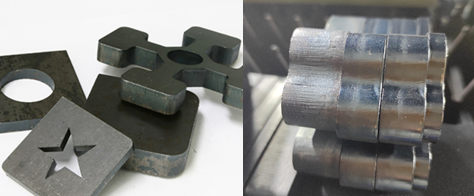

Cutting samples: