Guangyuan Technology (HK) Electronics Co., Ltd. |

|

Verified Suppliers

|

|

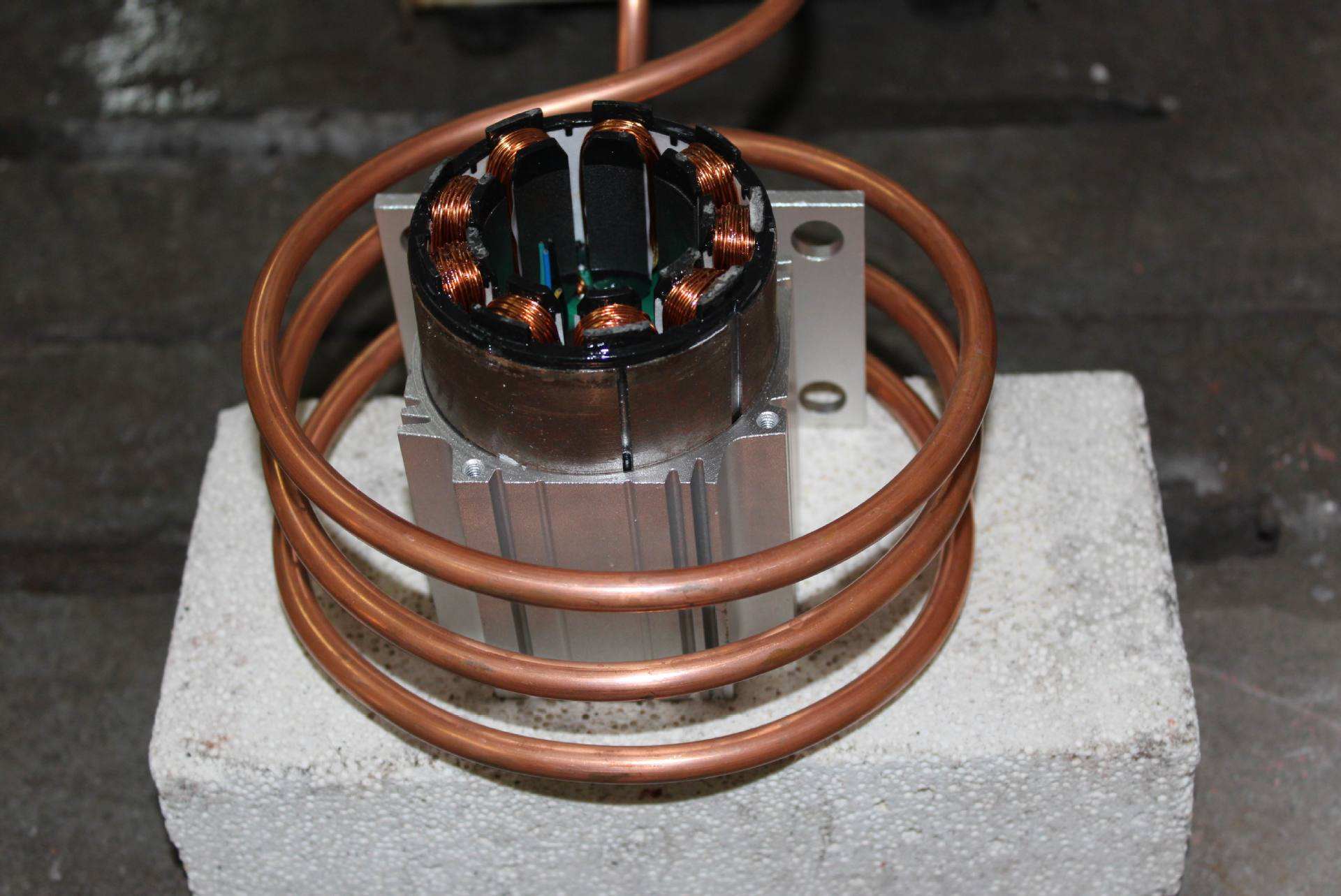

DSP Touch Screen 60KW 340V-430V Industrial Induction Heating Machine For Shrink Fitting

Induction heating is a fast, efficient, precise and repeatable non-contact method for heating metals or other electrically-conductive materials. The material may be a metal such as brass, aluminum, copper or steel or it can be a semiconductor such as silicon carbide, carbon or graphite.

Shrink Fitting is a process that is used in many industries. It especially has many applications in bearing manufacturing, shaft workpieces installation and fixation, and even the replacement of cutter heads for CNC tools, hot assembly, and hot disassembly. In the industrial mechanical manufacturing process, it is often necessary to assemble and disassemble other metal accessories on the shaft/sleeves workpiece. These accessories are generally assembled and disassembled by thermal expansion, such as the installation and disassemble of bearings, shafts, sleeves, tubes, hard alloy parts and the hot fitting of CNC machine tool heads, etc. The unique precision heating effect of induction heating equipment provides an excellent solution for the hot fitting process. The induction heating machine coil can be designed exactly according to the various metal workpiece shape and dimension. Moreover, the induction heating generator can also accurately control the output power in accordance with different heating speed needs. It allows the heating to be exactly focusing on the target heating zone. Because of the special features of the induction heating, more and more factories are now starting to use induction heating technology as a means of installation and disassembly. Induction heating equipment can quickly and conveniently heat the target area required by customers.

Power Requirements:

The power required to heat your work piece depends on:

After we determine the power needed to heat your work piece we can select the correct induction heating equipment taking the coil coupling efficiency into consideration.

The parameters of the DSP Touch Screen 60KW 340V-430V Industrial Induction Heating Machine For Shrink Fitting

| Model | GYHD-60AB (Three phase) |

| Work power | 340v-430v |

| Max input current | 90A |

| Max output power | 60KW |

| Fluctuating frequency | 80-200KHZ |

| The flow rate of cooling water | 0.15-0.3Mpa 7.6L/Min |

| Water temperature protection point | 40C |

| Product size | main :940x580x1020 mm |

| transformer :870x430x750 mm | |

| Net weight | main : 115 kg |

| transformer : 76.5 kg |

The advantages of the DSP induction heating machine:

1. Small size, light weight, no high pressure equipment, small footprint and movable operation;

2. Less power consumption and saving cooling water;

3. Fast heating and less oxide layer;

4. According to the size of the power, the frequency band is divided into a variety of models, customers can be selected according to the process requirements, in order to obtain a satisfactory performance price ratio;

5. The installation is simple, easy to operate, the user only needs to take 10 minutes to learn the entire operation process;

6. Fault detection and protection features complete:

The perfect fault detection and protection circuit monitors the faults of water shortage, overheating, overvoltage, overcurrent and lack of faults in real time, and responds quickly. The cause of the fault is displayed on the display screen at the right time, and the indicator light is synchronized; in addition, it can also be output by the output port. Relay signal for external system coordination work.

7. Resonant frequency automatic tracking system:

It completely solves the shortcomings of analog system frequency tracking and ensures the stability of IGBT resonant system; it can keep the output current or power unchanged even if the power grid fluctuates, and ensure that IGBT always works at zero current switch (ZCS) under any working condition. In the state, the IGBT is in the best working state, the power consumption is the smallest, and the whole machine is the most efficient;

8. Friendly man-machine interface:

Human-computer interaction can be selected in a variety of ways, LED indicator or digital tube display, touch screen display and control, text screen display, customers can choose as needed; from the function realization and operation settings, the traditional mechanical button panel is fully covered. Make operation and maintenance easier, more intuitive and more convenient;

9, Hardware isolation interface:

It is compatible with existing PLC on the market, which is beneficial to customers' functional transformation of existing PLC systems and further expansion of automation systems.

10. Remote communication interface:

With RS-23Z/RS-485/CAN communication interface, it can realize multi-machine network monitoring and control. The default RS485 adopts the common MODBVS communication protocol; 4-20MA or 0-10V interface can support closed-loop control with external system, such as temperature Closed loop control system.

11, zero power start: zero voltage output of start and standby, no need for false load support.

12, working mode: you can choose constant current, or constant power, you can also do constant voltage source output.

13. The device is equipped with a conspicuous red emergency stop button. When an emergency occurs, you can quickly press this button.

Stop the equipment work and use it to achieve protection measures.

14. The internal components of the equipment are reasonably laid out, and the main control circuit board is placed on the weak current side to avoid interference of the strong electricity to the control circuit and improve the control precision;

Applications of the industrial induction heating machine:

1. Heating (hot forging, hot fitting and smelting)

Hot forging aims to fabricate the work pieces of certain

temperature (different materials require different temperatures)

into other shapes through forging press with the help of punch

press, forging machine or other equipments, for instances, hot

extrusion of watch case, watch flan, handle, mold accessory,

kitchen and table ware, art ware, standard part, fastener,

fabricated mechanical part, bronze lock, rivet, steel pin and pin.

Hot fitting refers to the connection of different metals or metals

with nonmetals through the heating based on the principle of hot

expansion or hot smelting, for instances, embedded welding of

copper core of computer radiator with aluminum sheet and speaker

web, compound of steel and plastic tube, sealing of aluminum foil

(tooth paste peel), motor rotor and sealing of tubular electric

heating element.

Smelting mainly aims to melt the metal into liquid by using the

high temperature, which is mainly applicable to the smelting of

iron, steel, copper, aluminum, zinc as well as various noble

metals.

2. Heat Treatment (surface quench)

Quench for various hardware and tools, such as plier, wrench,

hammer, ax, screwing tools and shear (orchard shear).

Quench for various automobile and motorcycle fittings, such as

crankshaft, connecting rod, piston pin, chain wheel, aluminum

wheel, valve, rock arm shaft, semi drive shaft, small shaft and

fork.Various electric tools, such as gear and axes.

Quench for machine tools, such as lathe deck and guide rail.

Quench for various hardware metal parts and machined parts, such as

shaft, gear (chain wheel), cam, chuck and clamp etc.

Quench for hardware molds, such as small-size mold, mold accessory

and inner hole of mold.

3. Welding (braze welding, silver soldering and brazing)

Welding of various hardware cutting tools, such as diamond tool,

abrasive tool, drilling tool, alloy saw blade, hard alloy cutter,

milling cutter, reamer, planning tool and solid center bit.

Welding of various hardware mechanical gadget: Silver soldering and

brazing of metals of the same variety or different varieties, such

as hardware toilet and kitchen products, refrigerating copper

fitting, lamp decoration fitting, precision mold fitting, hardware

handle, eggbeater, alloy steel and steel, steel and copper as well

as copper and copper.

Compound pot bottom welding is mainly applicable to the braze

welding of circular, square as well as other irregular plain pot

bottom. It is also applicable to plain braze welding of other

metals.

Welding of heating disc of electric hot-water kettle mainly refers

to the braze welding of stainless steel flat base, aluminum sheet

and tubular electric heating elements of various forms.

4. Annealing (tempering and modulation)

Annealing of various stainless steel products, such as stainless

steel basin, annealed and extruded can, annealed folded edge,

annealed sink, stainless steel tube, tableware and cup.

Annealing of various other metal work pieces, such as golf ball

head, cue, brass lock, hardware copper fitting, kitchen knife

handle, blade, aluminum pan, aluminum pail, aluminum radiator and

various aluminum products.

GY had developed 27 years of research and is committed to providing customers with all kinds of medium frequency, high frequency, super audio frequency,ultrahigh frequency induction heating equipment, and automation equipment. We provide solutions for project planning, development, design, manufacturing and comprehensive after-sales service according to your needs. One-stop solutions for customer heat treatmen tneeds.The lates tDSP+FPGA all-digital control system products provide more professional, more accurate solutions and personalized high-quality products for many users on the road of innovation, transformation and transformation breakthroughs.

From 1996, devoted

For more than 20 years, GY has always been adhering to the company

philosophy of innovation, adherence to quality and excellent

operation. A single R&D office researches a single product.

After more than 20 years of hard work, it has developed steadily.

The current equipment users cover many industries such as

manufacturing, electric power and nuclear power,government science

reform, university scientific research, and special military

industry. In view of the different voltage levels in some

countries, the company has developed special input voltage

induction heating equipment for different frequency parameters. For

example, the input voltage suitable for use i n the United States,

Japan and other countries is single-phase 110V, three-phase 110V,

three-phase 220V, and three-phase 480V. Heating equipment and

heating equipment with input voltage of three-phase 415V and

three-phase 440V suitable for use in Southeast Asian countries such

as Malaysia, Australia and Thailand Inheritance builds trust.

Inherit and build trust

Made in China is facing global competition and challenges. To find

a suitable position in the international and domestic markets and

open up a larger market, we must use more advanced technology and

good after-sales service to improve ourselves. We will always be

committed to the application and promotion of GY series products in

the market with the spirit of pursuing professionalism, excellence

and perseverance, and seek cooperation with suppliers, agents and

users with professional technical support and good business

collaboration, common development and progress.