Guangyuan Technology (HK) Electronics Co., Ltd. |

|

Verified Suppliers

|

|

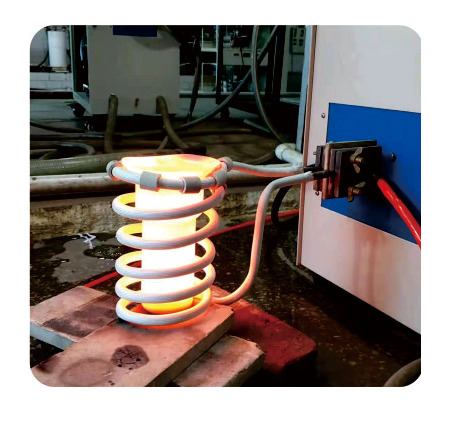

340V-430V High Frequency Industrial Induction Heating Machine With Automatic Feeding Sytem

INUCTION HEATING:

During induction heating GY currents are induced in an electrically conductive metallic workpiece by an alternating electromagnetic field. These are converted into heat by magnetic loss. – Or, simply put, the metal heats up due to the current flow produced in the workpiece. This enables induction heating to introduce heat directly into the workpiece rather than through connectivity from an external source such as heating with a flame or in a furnace. This process thus achieves a very high degree of efficiency. Additionally, heating can also be accomplished passing through non-conductive materials. The surrounding area is only heated indirectly.

The laws of Induction are the basis for all Induction heating

processes such as: induction hardening, induction tempering,

induction annealing, induction brazing, induction welding and other

hot forming technologies. GY generators have been specially

developed for induction heating. GY's large product portfolio of

Induction generators allows for the optimum solution for the

different applications.

Induction heating is a fast, efficient, precise and repeatable non-contact method for heating metals or other electrically-conductive materials. The material may be a metal such as brass, aluminum, copper or steel or it can be a semiconductor such as silicon carbide, carbon or graphite.

GY indcution heating had developed about 27 years of research and is committed to providing customers with all kinds of medium frequency, high frequency, super audio frequency, ultrahigh frequency induction heating machine, and automation equipment. We provide solutions for project planning, development, design, manufacturing and comprehensive after-sales service according to your needs. One-stop solutions for customer heat treatment needs.The latest DSP+FPGA all-digital control system products provide more professional, more accurate solutions and personalized high-quality products for many users on the road of innovation, transformation and transformation breakthroughs.

POWER REQUIREMENTS:

The power required to heat your work piece depends on:

After we determine the power needed to heat your work piece we can select the correct induction heating equipment taking the coil coupling efficiency into consideration.

The advantages of the DSP induction heating machine:

1. Small size, light weight, no high pressure equipment, small footprint and movable operation;

2. Less power consumption and saving cooling water;

3. Fast heating and less oxide layer;

4. According to the size of the power, the frequency band is divided into a variety of models, customers can be selected according to the process requirements, in order to obtain a satisfactory performance price ratio;

5. The installation is simple, easy to operate, the user only needs to take 10 minutes to learn the entire operation process;

6. Fault detection and protection features complete:

The perfect fault detection and protection circuit monitors the faults of water shortage, overheating, overvoltage, overcurrent and lack of faults in real time, and responds quickly. The cause of the fault is displayed on the display screen at the right time, and the indicator light is synchronized; in addition, it can also be output by the output port. Relay signal for external system coordination work.

7. Resonant frequency automatic tracking system:

It completely solves the shortcomings of analog system frequency tracking and ensures the stability of IGBT resonant system; it can keep the output current or power unchanged even if the power grid fluctuates, and ensure that IGBT always works at zero current switch (ZCS) under any working condition. In the state, the IGBT is in the best working state, the power consumption is the smallest, and the whole machine is the most efficient;

8. Friendly man-machine interface:

Human-computer interaction can be selected in a variety of ways, LED indicator or digital tube display, touch screen display and control, text screen display, customers can choose as needed; from the function realization and operation settings, the traditional mechanical button panel is fully covered. Make operation and maintenance easier, more intuitive and more convenient;

9, Hardware isolation interface:

It is compatible with existing PLC on the market, which is beneficial to customers' functional transformation of existing PLC systems and further expansion of automation systems.

10. Remote communication interface:

With RS-23Z/RS-485/CAN communication interface, it can realize multi-machine network monitoring and control. The default RS485 adopts the common MODBVS communication protocol; 4-20MA or 0-10V interface can support closed-loop control with external system, such as temperature Closed loop control system.

11, zero power start: zero voltage output of start and standby, no need for false load support.

12, working mode: you can choose constant current, or constant power, you can also do constant voltage source output.

13. The device is equipped with a conspicuous red emergency stop button. When an emergency occurs, you can quickly press this button.

Stop the equipment work and use it to achieve protection measures.

14. The internal components of the equipment are reasonably laid out, and the main control circuit board is placed on the weak current side to avoid interference of the strong electricity to the control circuit and improve the control precision;

Industrial Induction heating machine is widely used in the following industries:

Heat treatment industry (hardening, annealing, tempering and stress relieving):

The welding industry (brazing)

Forging industry

The precious metal smelting industry

Q1: Why should I trust your company and choose you?

A1: We are a professional induction heating equipment, set research

and develop sales, service as one of the high-tech enterprises. We

have 27 years of profession: equipment research and

development experience, is China's most professional bra heating

complete sets of automation equipment manufacturers.

Q2: Where is your company and can I come and visit it?

A2: Yes, Bajiaowo Industrial Park, Wanjiang District, Dongguan, Guangdong,

China. You are welcome to visit our factory anytime

Q3: How do I set up your machine

A3: We have paper installation instructions and videos, and we'll

teach them until you learn them.

Q4: Do you have any equipment in stock?

A4: Yes, we have some of our best-selling models in stock for

immediate delivery upon payment

Q5: Can you provide free samples of the machines?

A5: Sorry, we can't give you a free sample because of the high

price of the machines, we can sample test your workpiece for

free.Our machines are sure to meet your requirements and give you

satisfaction.

Q6: What is your quality control?

A6: We have A professional team responsible for product testing and

packaging before delivery, you can rest assured to buy.

Q7: How many days will it arrive after I buy the machine?

A7: Usually 5-7 workdays, but 20-30 days for large machines

Q8: What should I do if the machine breaks down?

A8: Within the one year warranty of the machine, we will provide

you with spare parts free of char For customers who buy the

machines, if they have any problems with the machines, they can

take pictures or record videos for us. We will guide the customer

to carry out repairs. If we still can't sol the problem, we can

send our engineer to your factory

Q9. What about the warranty?

A9: All of our products have a one-year warranty. During the

warranty period, spare parts will be replaced free of charge. We

provide lifelong technical support and other assistance.

WHY US?

GY offers a wide range of compact generators for induction

hardening that provide customers with the highest-quality in terms

of performance. With the precision frequency adjustment, even the

most demanding jobs can be completed with ease. To ensure that the

perfect solution is discovered for any application, the MIND range

of machines have been specially designed and manufactured to meet

customer requirements. Not only does eldec offer hardening systems,

but they also offer a wide range of generators, tools and brazing

and heating systems.