|

|

[China]

Trade Verify

Address: Bajiaowo Industrial Park, Wanjiang District, Dongguan, Guangdong, China

Contact name:Daisy

Guangyuan Technology (HK) Electronics Co., Ltd. |

|

Verified Suppliers

|

|

DSP High Frequency 100KW Induction Welding Equipment For Metal

Welding

INDUCTION WELDING EQUIPMENT :

Induction welding is a form of welding that uses electromagnetic

induction to heat the work piece. The welding apparatus contains an

induction coil that is energized with a radio-frequency electric

current. This generates a high-frequency electromagnetic field that

acts on either an electrically conductive or a ferromagnetic work

piece. In an electrically conductive work piece, such as steel, the

main heating effect is resistive heating, which is due to

magnetically induced currents called eddy currents.

In a ferromagnetic work piece nonmagnetic materials, such as plastics, can be induction-welded by formulating them with metallic or ferromagnetic compounds, called susceptors, that absorb the electromagnetic energy from the induction coil, become hot, and lose their heat energy to the surrounding material by thermal conduction.

TECHNICAL PARAMETERS OF THE INDUCTION WELDING MACHINE:

| Model | GYD-100AB (Three phase) |

| Work power | 340V-430V |

| Maximum input current | 150A |

| Output power | 100KW |

| Fluctuating frequency | 30-80KHZ |

| The flow rate of cooling water | 0.15-0.3Mpa 10L/Min |

| Water temperature protection point | 40C |

| Product size | main :874x520x1100 mm |

| transformer :870x430x750 mm | |

| Net weight | main : 115 kg |

| transformer : 76.5 kg |

APPLICATIONS OF THE INDUCTION WELDING MACHINE:

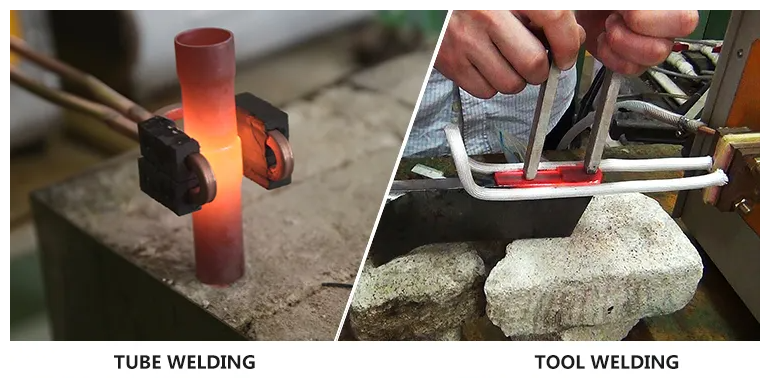

Metal tube welding:

Alloy cutter welding:

Carbide saw blade welding:

Metal welding:

Customized service:

THE ADVANTAGES OF THE INDUCTION WELDING:

THE ADVANTAGES OF THE DSP INDUCTION HEATING MACHINE:

1.FAST HEATING

2. WIDE COVERAGE OF HEATING

3. EASY INSTALLATION

4. EASY OPERATION

5. FAST START-UP

6. LOW POWER CONSUMPTION

7. HIGH EFFECTIVENESS

8. COMPREHENSIVE PROTECTION

9. CONTROLLABLE TEMPERATURE

10. COMPREHENSIVE FULL LOAD DESIGN

11. SMALL SIZE AND LIGHT WEIGHT

12. ELIMINATION OF HIGH VOLTAGE