Xinting Machinery Co., Ltd. |

|

16-630mm single screw plastic PE pipe extrusion line made in china

Product Description:

HDPE Single Screw Extruder, with different die head, and downstream

machines, which can produce different size of plastic pipe,

diameter ranging from 12mm to 1600mm.

WE use Siemens Beide motor, ABB inverter, Omron temperature

controller, and CHENG brand gearbox, etc. You can also choose PLC

touch screen to

control the operation, which can save the labor, and improve the

prduction efficiency.

Product Advantages:

1. Long groove between feed throat and screw to improve output

highly.

2. Accurate temperature control system on feed section to match

different plastics.

3. Unique screw design to achieve higher plasticizing and products

quality.

4. Gearbox of high torsion balance to realize stable running.

5. H shape frame to decrease vibrating.

6. PLC (Simatic Multi Panel) operation panel to ensure

synchronization.

7. Energy conservation, easy to maintenance.

Application Area:

1. Urban tap water supply, direct drinking water supply and

different quality water supply.

2. Coal gas, liquefied gas and natural gas distribution and

transportation.

3. Corrosive water drainage.

4. Water conservancy and farm irrigation works.

Guides before Quotation:

1. What is the raw material you are going to have crushing?

2. What capacity you want to get?

3. What is the size you want to get for the final material?

4. What is your power voltage ( Frequency, Phase)?

Pre-Sales and After-Sales Service:

1. Provide all the machines for the complete production according

to customer's requirements.

2. Provide complete service for factory layoutsand other

information to help customer to build the factory.

3. Provide the raw material to the customer if need.

4. Provide good service for machine installation and training,

until the customers can run the machines and make stable

production.

5. Provide after-sell service for all the life, except one year

quality guarantee,

6. Provide good quality, good price and good service to customer,

for long-term cooperation. We are the professional and trustable

supplier for turnkey projects. Let us do win-win business together.

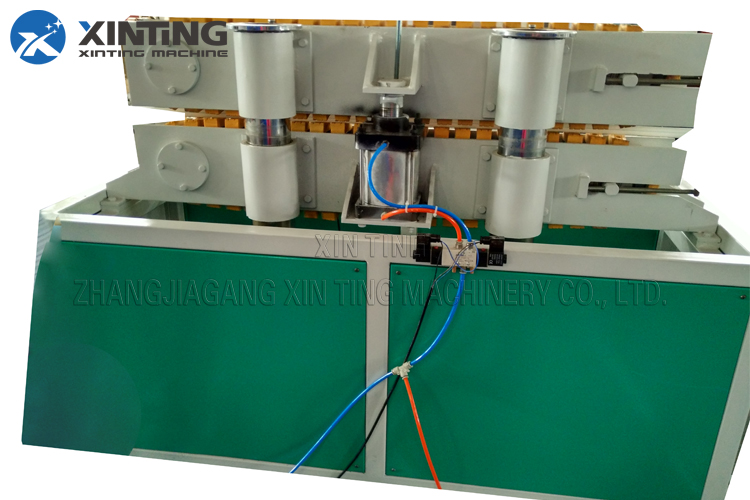

1. pe pipe production line process flow:

Vacuum loader → Hopper dryer→ Single screw extruder → PE pipe

mould→ Vacuum calibration tank→Shower cooling tank → Hauling off

machine → Chipless pipe cutting machine → Pipe stacker

2. pe pipe production line applications

PE pipe machine is mainly used to manufacturing PE plastic pipe,

and GF series tube auxiliary equipments can also use to process

oher plastic Extruder and GF series tube auxiliary equipments take

the features of advanced, reliable & applied together, and

provide strong certification for high-quality tube for customers

Main Technical Parameter:

| PE-63 | 65mm | 33:1 | 16-63 | 37 | 80 | 24 |

| PE-110 | 65mm | 33:1 | 75-110 | 55 | 110 | 30 |

| PE-160 | 75mm | 33:1 | 90-160 | 90 | 150 | 32 |

| PE-250 | 75mm | 33:1 | 110-250 | 110 | 200 | 42 |

| PE-315 | 90mm | 33:1 | 160-315 | 160 | 240 | 44 |

| PE-400 | 90mm | 33:1 | 200-400 | 185 | 300 | 50 |

| PE-500 | 120mm | 33:1 | 250-500 | 280 | 350 | 56 |

| PE-630 | 120mm | 33:1 | 315-630 | 280 | 480 | 56 |

| PE-800 | 150mm | 33:1 | 400-800 | 315 | 550 | 72 |

Zhangjiagang Xinting Machinery single screw extruder specially

designed for PP PE pellets extruding, it also can combine with the

PP PE PC pipe production line, PP PE PC profile production line.

We produce Single screw extruder, and also high speed high

efficient Single screw extruder.

Single screw extruder' screw structure also can re-designed

accoring to customer's detail raw material and the purposes.

we have many kind of types,such as

25/25;30/25;35/25;45/25;45/28;45/30; 45/33;50/28;55/25 ; 65/28;

65/30;65/33;70/30;75/33;90/30;90/33;120/15;120/22;120/32;120/33;130/32;150/10;150/30......etc

,

some small single screw extruder be equipped as colormark

co-extruder ,or lab extruder; some big single screw extruder

,together with our auxiliary machine,will be equipped as whole

production line to make pipe,to make profile, to make granule.

For pipe making machine, we can supply machine for pipe diameter

from 16mm to 1200mm,

different diameter range will be equipped with different machines.