Active Member

|

[China]

Address: Room 702-3,Ningbo Lishi Commercial building,Lane 578,45# Tiantong South Road,Yinzhou District,Ningbo,China

Contact name:Tina Kui

VAINO INTERNATIONAL LIMITED |

|

high effeciency energy saving injection molding machine with variable pump system

Detailed Product Description

Standard configuration:

Adopt famous hydraulic components:

Yuken-Japan pump,Yuken-Japan direction valve,

Hydraulic motor for melting plastic using intermot italy-China

Back pressure valve Yuken Japan

Air switch from LG Korea

Breaker AC contactor ,single phase breaker ,three-phase breaker from Schneider france

T-slot makes the adjustment easier, compare with the screw adjustment, it has better adaptability and longer life-span

SPECIFICATIONS

| SPECIFICATIONS | ||||

| DESCRIPTION | UNIT | K2-220 | ||

| INJECTION | A | B | C | |

| SHOT VOLUME | CM3 | 381 | 470 | 569 |

| SHOT WEIGHT | G | 347 | 429 | 520 |

| (PS) | OZ | 12.1 | 15.0 | 18.1 |

| SCREW DIAMETER | MM | 45 | 50 | 55 |

| INJECTION PRESSURE | MPA | 217 | 176 | 145 |

| SCREW L:D RATIO | 22:1 | 20:1 | 18:1 | |

| SCREW STROKE | MM | 240 | ||

| SCREW SPEED (STEPLESS) | R/MIN | 0~200 | ||

| CLAMPING UNIT | ||||

| CLAMPING FORCE | KN | 2200 | ||

| OPENING STROKE | MM | 480 | ||

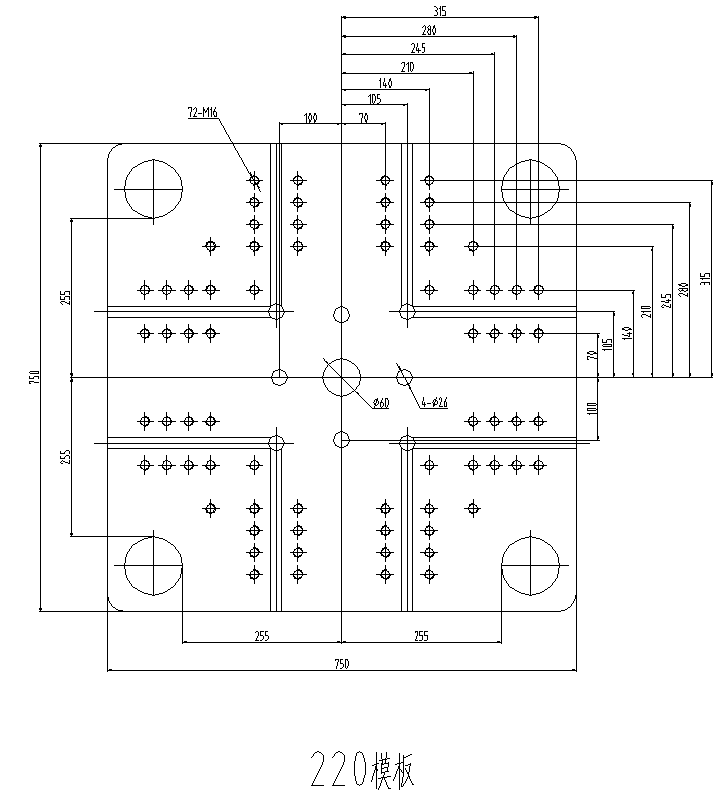

| PLATEN SIZE | MM*MM | 745*745 | ||

| SPACE BETWEEN TIE BARS | MM*MM | 510*510 | ||

| MOLD THICKNESS (MIN-MAX) | MM | 200~560 | ||

| MAX.DAYLIGHT | MM | 1040 | ||

| HYDRAULIC EJECTION STROKE | MM | 150 | ||

| HYDRAULIC EJECTION FORCE | KN | 67 | ||

| POWER UNIT | ||||

| HYDRAULIC SYSTEM PRESSURE | MPA | 17.5 | ||

| PUMP MOTOR(V/S) | KW | 18.5/28.3 | ||

| HEATING CAPACITY | KW | 13.1 | ||

| NUMBER OF TEMP CONTROL ZONES | 4+(NOZZLE ) | |||

| GENERAL | ||||

| DRY-CYCLE TIME | SEC | 4.5 | ||

| OIL TANK CAPACITY | L | 310 | ||

| MACHINE DIMENSIONS | MXMXM | 5.4*1.3*2.1 | ||

| MACHINE WEIGHT | KG | 6800 | ||

HYDRRULICS

Variable displacement pump System

Servo System

Oil suck filiter

Oil temperature control and alarm

By-pass oil filter

ELECTRONICS

8.7' lcd solor screen

200sets of mold memory

Barrel temperature monitoring and thermocouple break alarm

System hardware i/o testing function

Interface for printer and floppy drlver

Electric motor safety protection

Emergency stop safeguard device

RCCESSORIES

Adlustable machine leveling pads

Easily damaged spare parts

Professional tools

Manual

OPTIONRL DEVICE

Wide range of injection unit for specific appliaction

Spacific material screw and barrel

Accumulator fast injection

Core pull fittings

Air blast fittings

Glass water regulations

Extended nozzle