Dongtai Yaoqiang machinery Co.,Ltd |

|

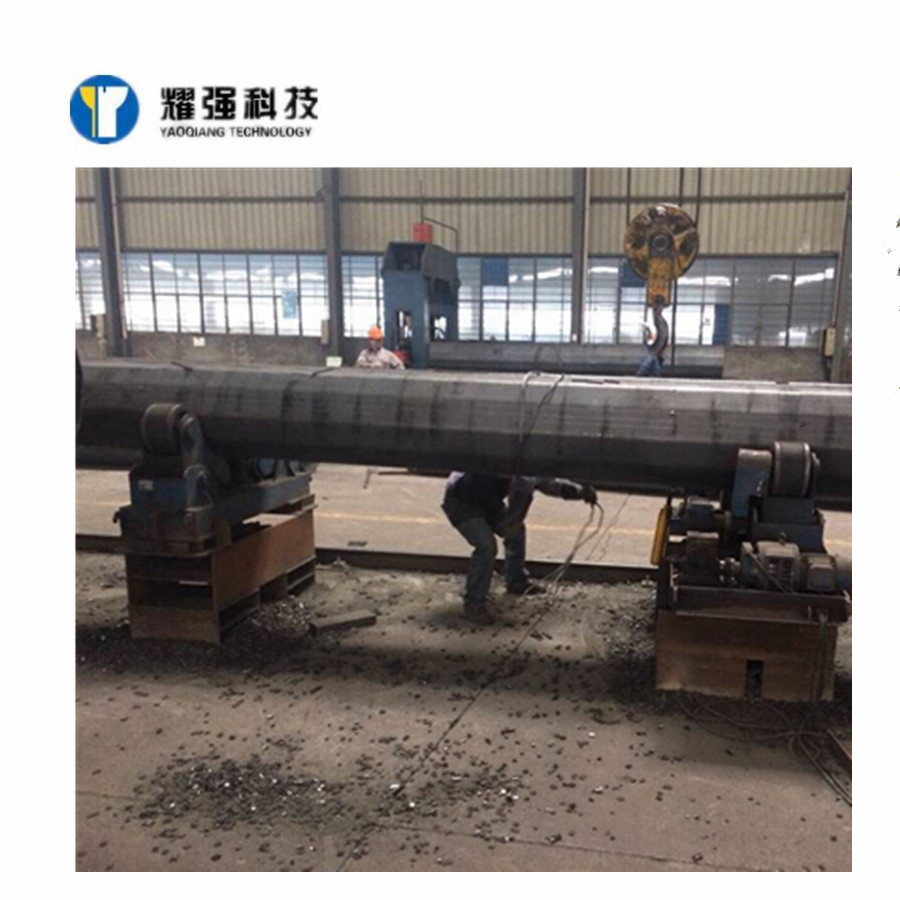

LH4000 Power rod external longitudinal seam welding machine cantilver seam welding machine

Power rod external longitudinal seam welding machine cantilver seam welding machine is developed successfully by our company according to the particularity of welding of round work-piece, combined with the technical experience of developing welding equipment of our company for many years.

Power rod external longitudinal seam welding machine is mainly composed of the car body, column, skateboard mechanism, walking reducer, welding torch cross adjusting parts, Flux recovery treatment system, electrical control system and submerged arc welding machine and other components.

| Item | Program | Unit | LH4000 |

| 1 | Structure type | Gantry moving | |

| 2 | Rail gauge | MM | 4000 |

| 3 | Net height of gantry | MM | 4000 |

| 4 | Work-piece length | MM | 250-1500 |

| 5 | Welding arm lifting length | MM | 1350 |

| 6 | Welding arm moving speed | MM/MIN | 100-1000 |

| 7 | Gantry weld moving speed | MM/MIN | 100-1000 |

| 8 | Speed adjust of welding arm & gantry | Ac frequency conversion | |

| 9 | Gantry driving mode | R Series worm gear reducer+gear pair+road wheel(friction pair) | |

| 10 | Trailing board left and right walking mode | electric |

The steel property and strength of the machine are calculated in detail, the design is advanced and reasonable, the main parts are treated by stress removal after welding, the operation is safe and reliable, and the service life is long.

The gantry support moves, the work-piece is placed on the inside auxiliary support to hold still for welding.

The main engine of this cantilever seam welding machine uses two reducers to drive two spindle rotation, such two-axis four-wheel drive to avoid slippage, crawling and other phenomena.

The bilateral synchronous drive is realized by frequency conversion control, and the wheel mechanism is arranged on the side of the rail, which ensures the running speed of the gantry frame is stable and safe.

The front part of the upper platform is made into a slide moving guide, used to install the welding arm and so on, the upper platform can place the wire plate and so on.

The next platform is placed with a recycling machine, which is convenient to ash out and reduces crawling up and down. The collector is used to recover, separate and screen the flux after submerged arc welding, remove the flux and dust that have been sintered into blocks, and recycle the reused flux that has not yet been sintered.

The welding arm is driven up and down by the mechanical electric gear rack, and the welding arm body has no dynamic movement on the left and right, so that the welding arm can automatically return to position and align automatically to suit the welding of different sizes of section steel.