Zhengzhou Huitong Pipeline Equipment Co.,Ltd. |

|

Super Duplex Stainless Steel S32750 W.Nr.1.4410 SAF 2507 bolt nut stud washer thread rod manufacuter

1. Duplex stainless steel 2507 bolt nut stud washer fasteners

2507 1.4410 hex bolt, duplex stainless steel S32750 full threaded hex bolt DIN933, 1.4410 S32750 hex bolt with partial thread as per DIN931, W.Nr.1.4410 nut with hex round square head, duplex steel 2507 hex nut as per ASME DIN ISO standard, S32750 flat plain spring lock washer manufacturer

2. S32750 bolt nut stud washer specification

| Type | Hex bolt(full thread, partial thread), threaded rod, U-bolt, Spring washer, hex nut, flat washer, spring washer |

| Size | DIN STANDARD:M6-M100 ASME STANDARD:1/4”-2 1/2” |

| Surface | Cold/hot galvanized, PTFE, Zinc Nickel, Black coating, Plain |

3. Other bolt nut washer thread rod we have

| Type | Stud Bolt Hex Bolt (full thread,partial thread) Thread Rod U-Bolt U Hex Socket Cap Screw Hex Nut Flat Washer Spring Washer |

| Size | DIN: Stud Bolt :M6~M100 , Hex Bolt :M6~M64 |

| ASME: Stud Bolt:1/4"~5", Hex Bolt :1/2"~2 1/2" | |

| Finish | Cold galvanizing ,Hot-dip Galvanizing ,PTFE ,Zinc Nickel ,Black coating ,Plain |

| Producing Standard | ASME : |

| ASME B18.2.1 | |

| ASME B18.2.2 | |

| ASME B18.22.1 Plain Washer | |

| DIN: | |

| DIN931 Hex Bolt with partial thread | |

| DIN 933 Hex Bolt with full thread | |

| DIN 912 Hex Socket Cap Screw | |

| DIN 934 Hex Nut | |

| DIN 125 Plain Washer | |

| DIN127 Spring Washer | |

| DIN 975 Threaded Rods | |

| DIN 976 Stud Bolts | |

| DN 3570 U-Bolt | |

| Material Grade | Stainless Steel : 304/304L,316/316L,316Ti, 317/317L, 321, 347/347H, 310, 309, A453 660C ,660D S31254 /254SMO, 904L /1.4539 /N08904,N08367 ,N08926 / 1.4529 |

| Duplex Steel: 2205 /S31803 ,S32750/2507 ,S32760 | |

| Nickel Alloy Steel : UNS N02200/Ni 200, UNS N02201 /Ni201, UNS N04400/ Monel 400,Monel K500 , UNS N06600/Inconel 600 ,UNS N06601/ Inconel 601 ,Inconel 625 , UNS N08800 /Incoloy 800 ,UNS N08810 /Incoloy 800HT ,UNS N08811 /Incoloy 800HT, UNS N08825/ Incoloy 825 UNS N06002 /Hastelloy X, UNS N06022/ Hastelloy C22, UNS N06200/C2000, ,UNS N10276/ Hastelloy C276, UNS N10665 /Hastelloy B2, UNS N10675/Hastelloy B3 , UNS N08020 /Alloy 20, UNS N08031/Alloy 31 | |

| Carbon Steel : Grade 4.8 ,6.8 ,8.8 ,10.8 ,12.9 | |

| Alloy Steel: A193 B7 ,A194 2H , A320 L7,L7M |

4. Types of S32750 2507 1. 4410 bolt nut washer stud

| S32750 bolt | S32750 bolt S32750 full thread hex bolt 2507 bolt duplex stainless steel 2507 hex bolt 1.4410 partial thread hex bolt |

| S32750 nut | 1.4410 nut W.Nr.1.4410 hex nut DIN standard Duplex stainless steel S32750 nylon nut lock S32750 hex nut coarse thread |

| S32750 stud | 2507 stud bolt DIN 1.4410 full thread stud bolt S32750 stud bolt as per DIN975 |

| S32750 washer | 2507 flat washer 2507 1.4410 S32750 Plain washer WERKSTOFF NR.1.4410 flat washer S32750 spring washer Duplex steel S32750 spring lock washer |

5. S32750 2507 1. 4410 bolt nut stud washer Chemical Composition

UNS S32750

Forms of Super Duplex 2507 Available

• Sheet

• Plate

• Bar

• Pipe & Tube (welded & seamless)

• Fittings (i.e. flanges, slip-ons, blinds, weld-necks, lapjoints,

long welding necks, socket welds, elbows, tees, stub-ends, returns,

caps, crosses, reducers, and pipe nipples)

Duplex 2507 Overview

Duplex 2507 is a super duplex stainless steel designed for

applications which demand exceptional strength and corrosion

resistance. Alloy 2507 has 25% chromium, 4% molybdenum, and 7%

nickel. This high molybdenum, chromium and nitrogen content results

in excellent resistance to chloride pitting and crevice corrosion

attack and the duplex structure provides 2507 with exceptional

resistance to chloride stress corrosion cracking.

Usage of Duplex 2507 should be limited to applications below 600° F

(316° C). Extended elevated temperature exposure can reduce both

the toughness and corrosion resistance of alloy 2507.

Duplex 2507 possesses excellent mechanical properties. Often a

light gauge of 2507 material can be used to achieve the same design

strength of a thicker nickel alloy. The resulting savings in weight

can dramatically reduce the overall cost of fabrication.

Corrosion Resistance

2507 Duplex is highly resistant to uniform corrosion by organic

acids such as formic and acetic acid. It is alsohighly resistant to

inorganic acids, especially if they contain chlorides. Alloy 2507

is highly resistant to carbide-related intergranular corrosion. Due

to the ferritic portion of the duplex structure of the alloy it is

very resistant to stress corrosion cracking in warm chloride

containing environments. Through additions of chromium, molybdenum

and nitrogen localized corrosion such as pitting and crevice attack

are improved. Alloy 2507 has excellent localized pitting

resistance.

What are the characteristics of Duplex 2507?

• High resistance to chloride stress corrosion cracking

• High Strength

• Superior resistance to chloride pitting and crevice corrosion

• Good general corrosion resistance

• Suggested for applications up to 600

• Low rate of thermal expansion

• Combination of properties given by austenitic and ferritic

structure

• Good weldability and workability

Chemical Composition, %

| Cr | Ni | Mo | C | N | Mn |

| 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.030 Max | .24-.32 | 1.20 Max |

| Si | Cu | P | S | Fe | |

| 0.80 Max | 0.50 Max | 0.035 Max | 0.020 Max | Balance |

In what applications is Duplex 2507 used?

• Desalination Equipment

• Chemical process pressure vessels, piping and heat exchangers

• Marine Applications

• Flue Gas Scrubbing Equipment

• Pulp & Paper Mill Equipment

• Offshore Oil production/technology

• Oil and gas industry equipment

ASTM Specifications

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Flanges & Fittings |

| A790 | A790 | A789 | A789 | A240 | A276 | A182 |

Mechanical Properties

Specified Tensile Properties, Plate ASTM A240

| Ultimate Tensile Strength, ksi Minimum | .2% Yield Strength, ksi Minimum | % Elongation Min. | |

| 116 | 80 | 15 | 310 |

6. S32750 2507 1.4410 bolt nut washer stud Application Industries

7. S32750 2507 1.4410 bolt nut washer stud Test Certificates

We provide Manufacturer TC (Test Certificate) in accordance to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

• EN 10204/3.1B,

• Raw Materials Certificate

• 100% Radiography Test Report

• Third Party Inspection Report, etc

ASME, ASTM and API S32750 bolt nut washer stud Value Added Services

Material Testing:

We ensure that all our materials go through strict quality tests before dispatching them to our clients.

• Mechanical Testing Such as Tensile of Area

• Hardness Test

• Chemical Analysis – Spectro Analysis

• Positive Material Identification – PMI Testing

• Flattening Test

• Micro and MacroTest

• Pitting Resistance Test

• Flaring Test

• Intergranular Corrosion (IGC) Test

Documentation

• Commercial Invoice which includes HS Code

• Packing List including net weight and gross weight, number of boxes, Marks and Numbers

• Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

• Fumigation Certificates

• Raw Material Test Reports

• Material Traceability Records

• Quality Assurance Plan (QAP)

• Heat Treatment Charts

• Test Certificates certifying NACE MR0103, NACE MR0175

• Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

• Guarantee Letter

• NABL approved Laboratory Test Reports

• Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

• Form A for the purposes of the Generalized System of Preferences (GSP)

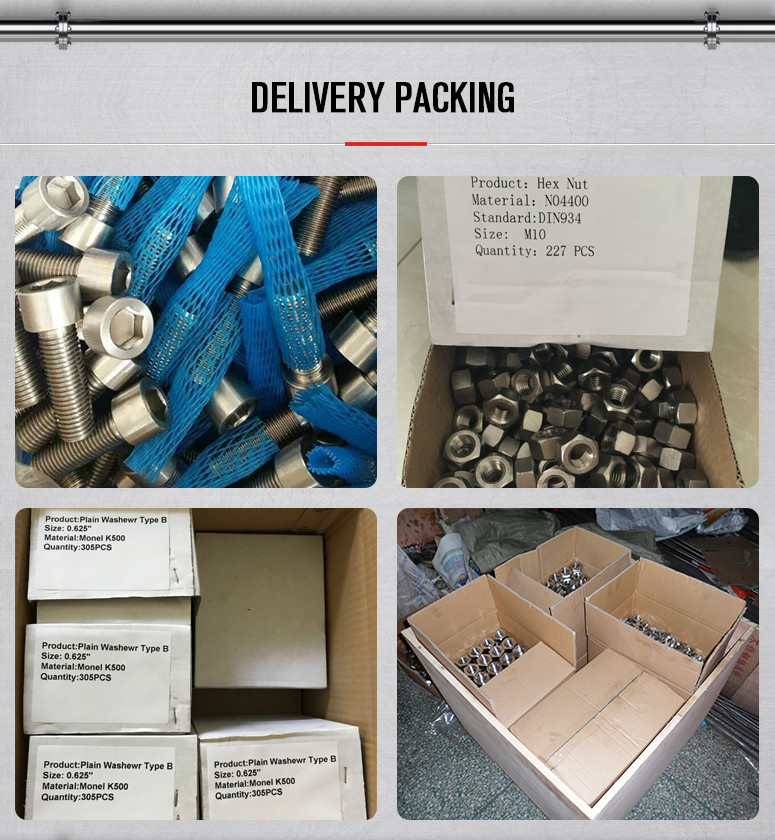

8. S32750 2507 1.4410 bolt nut washer stud Package

9. S32750 2507 1.4410 bolt nut washer stud Popular Searches

S32750 bolt, 1.4410 full thread hex bolt, S32750 bolt, duplex stainless steel S32750 hex bolt, S32750 2507 1.4410 partial thread hex bolt, 2507 flat washer, 2507 1.4410 S32750 plain washer, WERKSTOFF NR.1.4410 flat washer, 2507 spring washer, Duplex steel 2507 spring lock washer

10. FAQ

FAQ:

Q:How does your factory do regarding quality control?

A:Quality is priority. we always attach great importance to quality

controlling from the beginning to the end.Mill Test Certificate is

supplied with shipment. If needed, a Third Party Inspection is

acceptable.

Q:May I have some samples before bulk order?

A:Yes, of course. samples are free but you have to pay the courier.

Q:Can we visit your Company?

A:Surely. Welcome to China and we will be honored to have a

customer and friend.

Q:What is the payment terms?

A:T/T, L/C ,Western Union,etc.

Q:What's your delivery time?

A:For stocks, we can send the goods to loading port within 7 days

after receiving your deposit.

For production period, it usually needs about 10days- 60days after

receiving the deposit.

Q:Is it OK to mark my logo on your products?

A:Yes. OEM and ODM are available for us.