Jiangsu Hanpu Mechanical Technology Co., Ltd |

|

Verified Suppliers

|

|

Size-customizable Stainless Steel Dimple Plate For Heat Exchanger

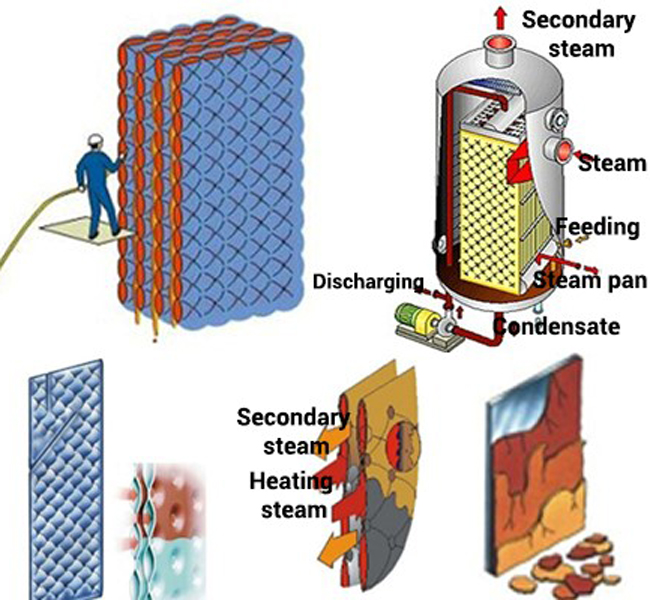

Evaporation plants are well-proven in installations around the world. There are a variety of configurations and models available – from pre-evaporators to multiple-effect evaporation trains – to accommodate even the most challenging pulp mill or effluent plant evaporation needs

The major advantage to multiple-effect evaporators is the utilization of proven lamella heating surfaces for high efficiency and reliability.

pp-evaporation-plant-lamella

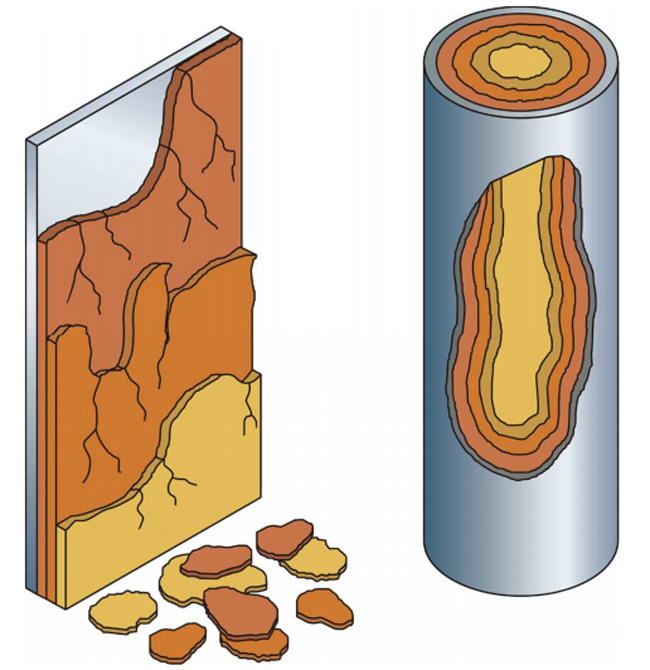

Evaporation plant lamellar

lamella heating surface

| Name | Pillow plate series | Shell and tube heat exchanger | Detachable plate heat exchanger | Spiral plate heat exchanger |

| Operating temperature range | <800℃ | <800℃ | <170℃ | <350℃ |

| Maximum pressure | <60 bar | <200 bar | <32 bar | <25 bar |

| Heat transfer coefficient to water[W/m2·℃] | 3500 | 2700 | 5600 | 2000 |

| Application of air and water heat exchange | fit | fit | not fit | Partial fit |

| Immersion in tank or water | fit | Partial fit | not fit | not fit |

| Welding of tank and reactor | Applicable | not applicable | not applicable | not applicable |

| Install into the existing reactor and other equipment | Flexible application | Partial applicable | not applicable | not applicable |

| All welded construction | Applicable | Applicable | not applicable | not applicable |

| Heavily contaminated liquids and other applications | Applicable | Applicable | Partial Applicable | Applicable |

| Weight per unit area | low | high | low | high |

| Falling film, condenser and evaporator | fit | fit | Partial fit | Partial fit |

Black Liquor is a by-product of pulp from mills that make products from trees, such as paper. It is currently used to recover cooking chemicals and produce high-pressure steam used in the pulp and paper-making process. It is composed of different ingredients from these processes such as lignin, hemicellulose, sodium hydroxide (NaOH) and sodium sulfide (Na2S). The lignin compound in black liquor can be used to make biofuel but it can be expensive to produce and so fuel made from it is not very common.

However, and according to the International Energy Agency (IEA), the future of using black liquor as fuel is promising and it is seen as the fifth most important fuel on earth!

Black liquor evaporation

Black liquor recovered from pulping contains 14-17% dissolved solids

These solids are composed of about 1/3 inorganic chemicals that were in the white liquor added to the digester

The remaining 2/3 consist of the organic chemicals extracted from the wood

Black liquor must be concentrated to above 60% solids so that it will burn without supplemental fuel

Basic process requirements

Efficient use of energy

Efficient separation of water vapor from black liquor

Proper separation of methanol, tall oil soap

Concentration of black liquor to 75-85% dry solids

Evaporation

Mission:

Evaporation of weak black liquor to separate water and create a combustible product-strong black liquor

The three main processes that occur in the evaporator are:

Black liquor+heat to Strong Black liquor + Water + Steam

Condensate + Steam to Clean + Dirty condensate + NCG

Black liquor to Black liquor + Soap (only softwood)

How to reach 80-85% dry solids?

Due to the high viscosity

MP-steam as heating medium

liquor temperature 175 ℃ in final concentrator

Liquor retention time

evaporator acts also as a LHT-reactor

Duplex construction material

high alkali content may cause Stress Corrosion Cracking (SCC)

Energy-efficiency for reduced costs

Highest dry solids liquors with maximum availability using crystallization technology

Cleanest reusable condensates using the minimum amount of steam

Lowest steam and electricity consumption

Self-cleaning

Tolerate even non-soluble scaling