Jiangsu Hanpu Mechanical Technology Co., Ltd |

|

Verified Suppliers

|

|

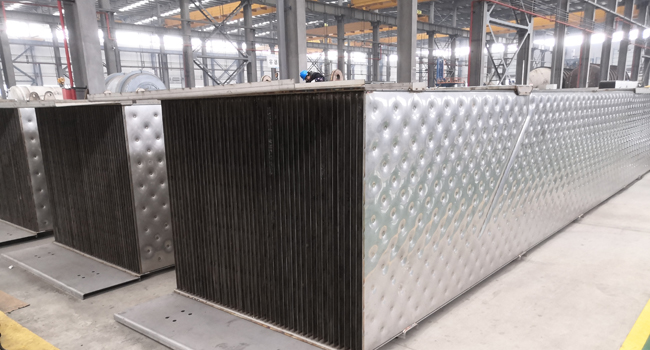

Pillow plate jacket laser laser welding type evaporator for paper production waste water

INTRODUCTION

Weak Black Liquor (WBL) from the brown stock washers is typically at 13-18%TS. Most of this water content must be evaporated to produce a material with high enough solids to support effective combustion in the recovery boiler, typically between 65% and 80%TS.

During evaporation to this level of solids, various volatile components (sulfur compounds, methanol, etc.) are released from the liquor and must be separated from the condensate to allow reuse in the fiberline and recausticizing. From this point of view, the evaporation plant actually serves as a"water factory"within the mill. Black liquor also contains a substantial fraction of inorganic compounds which, during the evaporation process, reach their solubility limit and can deposit as scale on the evaporator heat transfer surfaces greatly limiting the operating capacity of the evaporation plant and of the entire recovery island.

The inherent complex composition of black liquor translates into several interdependent design requirements for the evaporators:

The evaporation plant must efficiently transfer heat for the evaporation of the black liquor.

It must do so while avoiding scale formation on the heat transfer surfaces.

The evaporation plant must also produce sufficiently cleancondensate fractions to satisfy the needs of the pulp mill and recausticizing area, thus greatly reducing the fresh water intake of the mill.

Volatile components and NCGs must be removed and conditioned for safe disposal via incineration.

EVAPORATOR EQUIPMENT

There are two basic types of evaporator equipment in service today for black liquor evaporation:

Rising Film Evaporators

Also referred to as a Long Tube Vertical (LTV) evaporator, this design has dominated the Industry for decades and remains a common sight in older mill operations.

Falling Film (FF) Evaporators

This evaporator design relies either on tubes or plates as heat transfer surfaces. Liquor is processed on the inside of the s intubular units but on the outside of the heat transfer surface in plate designs.

FF evaporators consist of a liquor sump from which a defined volume of liquor is continuously recirculated to the top of the heating element

A distribution device,typically a tray or a spray nozzle in some designs, then distributes the flow of liquor over the entire heating surface. Holes in tubular units or slots for plate units are positioned to allow the liquor to fall onto the tubesheet or the plates.Even distribution ofliquor is a critical consideration for this type of designs and both the tray and the tubesheet(or plate element) must all be level.

Following the distribution device,a thin film of liquor is established on the heating surfaces and flows downward back to the liquor sump while being partally evaporated. Heat-transfer rates are considerably better,especially at higher concentrations, when using falling film designs over rising film designs since the liquor falls turbulently over the heating surface. Any liquor preheating requirement is also efficiently accomplished in the falling film design.

Mechanical Vapor Recompression MVR Evaporator consumption compared with traditional evaporation equipment calculated by evaporating 1T water

| Name | Steam | Electric Power | Total Cost (RMB) | ||

| Evaporation Capacity (kg/h) | Consumption (T) | Cost (RMB) | Consumption (kw) | Cost (RMB) | |

| Single Effect Evaporator | 1.1 | 220 | 3 | 2.1 | 222.1 |

| Double Effect Evaporator | 0.55 | 110 | 3 | 2.1 | 112.1 |

| Three Effect Evaporator | 0.4 | 88 | 3 | 2.1 | 90.1 |

| MVR Evaporator | 0.02 | 4.4 | 30 | 21 | 25.4 |

The heat transfer plate consists of two thin plates, which are

completely welded around by laser welding process, and the middle

area is full of pillow pattern; after forming process, pillow

shaped cavity is formed inside the heat transfer plate. Pillow

design creates excellent turbulence and provides self-supporting

structure. In practical application, additional welding path is

often added in the heat transfer plate to adjust and control the

interface position of fluid in and out of the heat transfer plate,

the flow velocity and flow rate of fluid in the plate, so as to

optimize the heat transfer effect.

Advantages of heat transfer plate technology:

1) Excellent turbulence design, high heat transfer coefficient;

2) high welding reliability;

3) small resistance on the external surface, not easy to produce

dirt;

4) high temperature and high pressure resistance;

5) wide channel, low pressure drop, easy to clean;

6) flexible shape design, optimization of heat transfer effect.

Production Equipment and Capability