Zhangjiagang Guangda Special Material Co., Ltd. |

|

Verified Suppliers

|

|

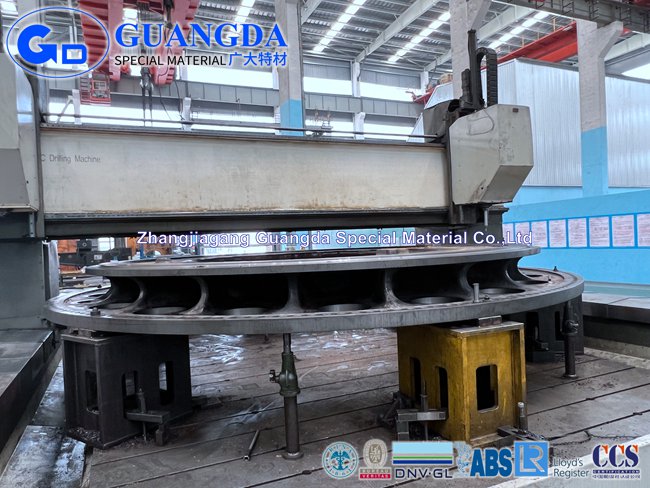

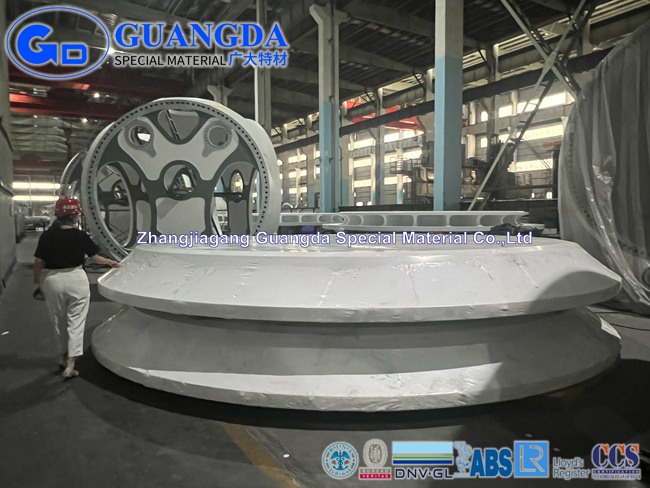

Wind Turbine Yaw Base Plate , Wind Turbine Castings Spheroidal Graphite Iron Castings EN-GJS-500-7 , QT500-7

Yaw Base plate connect the Nacelle Head Carrier and Yaw Bearing Spacer in wind turbine .Hydraulic station , yaw drive and yaw drive and yawbrake are installed on Yaw Base Plate .

Guangda could provide different kinds of the large parts castings as customer's requirements .Guangda has specialized large-scale casting production lines, and strives to build a high-power wind power equipment industry base, and mass production of castings that meet various technical requirements. A full-chain wind power industry cluster integrating wind power equipment design, casting, processing, painting and transportation has been formed.

Wind turbine castings Description

| Application | Yaw base plate , yaw bearing support , yaw bearing bracket |

| Steel Grade | Spheroidal cast irons QT500-7 |

| UT | EN12680-3 |

| MPI | EN1369 |

| Metallic products inspection | EN10204-2004 |

| Surface treatment | Sand blasting ,Corrosion protection and painting |

Comparison - Equivalent Grades of Ductile Iron (SG Iron, Nodular Graphite Iron)

| ISO | 500-7/S | France | FGS500-7 |

| Australia | 500-7 | UK | 500/7 |

| USA | 70-50-05 | India | SG500/7 |

| Germany Austria | GGG50 | Spain | FGE50-7 |

| European | EN-GJS-500-7 | Belgium | FNG50-7 |

| China | QT500-7 | Sweden | 0727-02 |

| Japan | FCD500 | Norway | SJK-500 |

| Italy | GS500-7 |

Wind turbine castings test

Guangda wind turbine products overview

| Wind turbine casting parts | Rotor Hub, Nacelle head carrier , Main carrier, Main shaft ,Shaft sleeve, Torque arm ,Shell frame, Support base , Yaw base plate, Planet carrier ,Cover, Frame, Ring , Tower connection part, Nacelle connection part, All kinds of the structure parts for the widn turbines . |

| Wind turbine forging parts | Main shaft, Flange, Yaw flange ,Rolled Ring, Flanges , Gear box parts etc. |

| Wind turbine gear box parts | Torque arm ,Planet shaft, Sun shaft, Planet gear, Internal gear, Planet carrier, Gear box cover etc. |

About Guangda

Guangda is a professional manufacturer for the wind turbine parts including the wind turbine castings ,forgings and gear box parts . As we are an integrated steel manufacturer from smelting, forging,casting, heat treatment to precision smart manufacturing .We could provide rough blank or semi-finishing or finishing parts for the wind power industry .

We have deep cooperation with ZF, Mingyang ,DEC,Windey, Envision, NGC,Flender,Shanghai electric ,CRRC.

| Company type | Science and Technology innovation board listed company. Stock code :688186 |

| Annual capacity for the castings | 210,000.00 ton |

| Max length/Diameter | 15m |

| Max weight | 200T |

| Products type | 2MW 3MW 3.2MW 3.6MW 4MW 4.5MW 5MW 5.5MW 6.25MW 7MW 8MW 8.3MW 11MW 12MW 16.6MW etc |

| Material | QT350-20 ,QT400-18, QT450-10,QT500-7, QT500-14,QT600-3, QT700-2, QT800-2 ,HT200, HT250, HT300,RUT300 etc. |

| Machining | Turning, milling, boring ,grinding, finished machining, gear shaping ,gear hobbing, gear grinding capability. |

| Heat treatment | Normalizing, QT, annealing, carburizing, nitriding with complete heat treatment capacity |

| Surface treatment | High-pressure cleaning, sand blasting and thermal spraying. Complete surface treatment capability. |

Casting

Machining

Surface treatment

UT

After paint

Packing

ductile iron foundry

sand casting foundry

Huge casting