Zhangjiagang Guangda Special Material Co., Ltd. |

|

Verified Suppliers

|

|

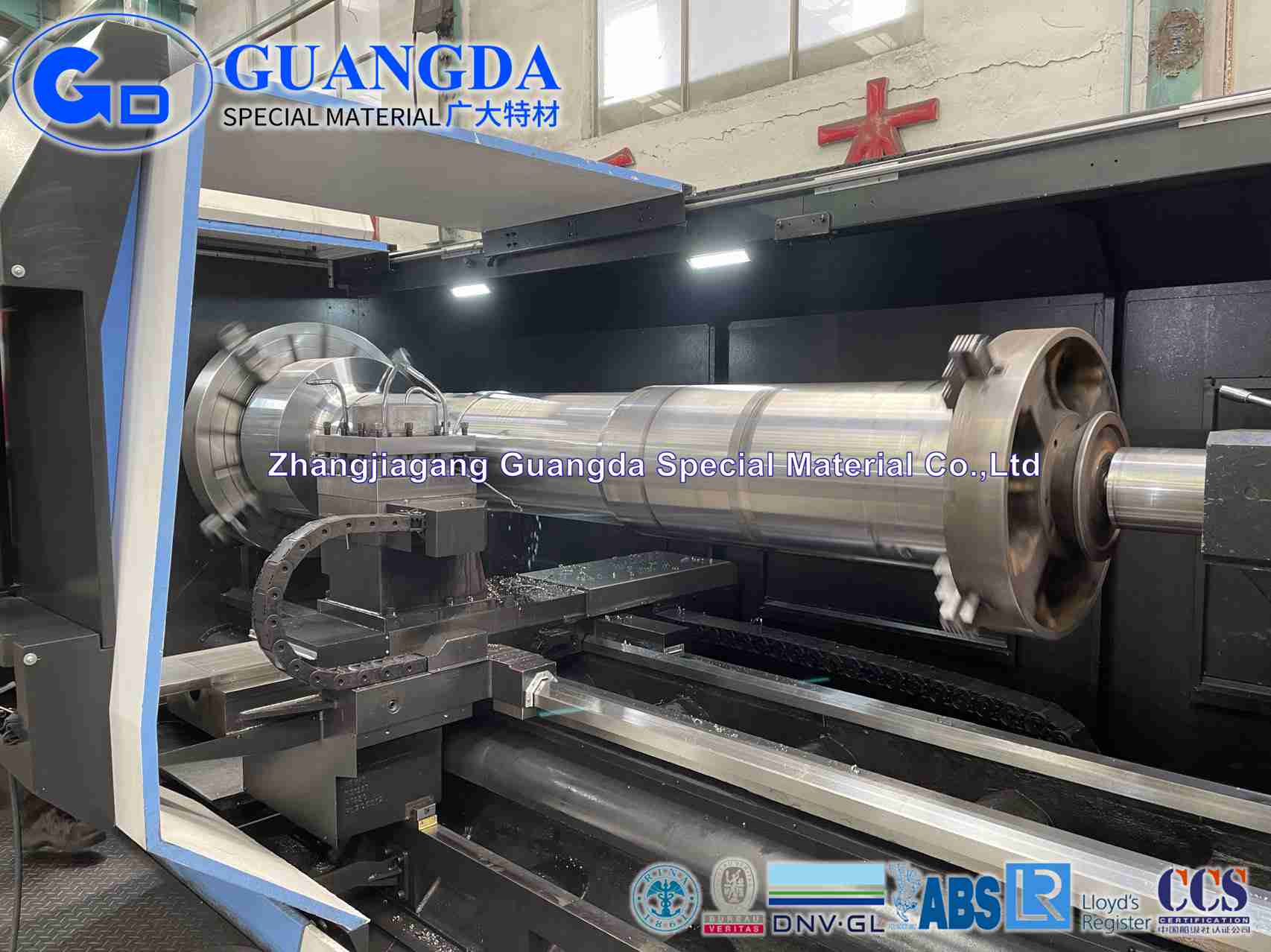

Drive Shaft Manufacturer Horizontal Shaft Prop Shaft Manufacturers

The material used needs to have a high tensile and endurance strength to withstand static and dynamic loads. If gears are attached to the shaft, the gear is usually made from an extremely durable material, such as carbon steel. These can be further hardened by heat treatment.

Quality manufactured shaft can extend the life and reliability of many critical components used in various industries with demanding operating conditions such as in marine, hydropower, wind, pulp & paper, oil & gas, and manufacturing.

Most importantly, Guangda has an experienced team of engineers and technicians who can tackle any challenging project. The shaft manufacturing process at Guangda starts and ends with an engineering-focused approach, valuing quality control with comprehensive initial and final dimensional checks.

Forged shaft drive shaft manufacturer Products features

| Application | Coupling shaft |

| Smelting | EAF+LF+VD |

| UT | SEP1921,EN10228-3 C/c D/d |

| Heat treatment | Normalized , queching and tempering ,stress relief |

| Delivery condition | Rough ,Semi-finished ,finished |

| Standard | EN10250,EN10083,SEW550 etc. |

| Equiment | 5000T pressing machine |

Axle shaft forgings Material

| Type | Material |

| Carbon steel | C15,C22,C25,C30,C35,C40,C45,C50,C55,C60,S355J2G3 etc. |

| Alloy steel | 25CrMo4,42CrMo(S)4,AISI4130,AISI4140,AISI4150,34CrNiMo6,30CrNiMo8,31CrMoV9, |

| Stainless steel | 630 17-4PH,630 17-7PH, 632 15-7MoPH,XM12 15-5PH,2205,2507,F55,2205 etc. |

| Tool and die steel | H11-1.2343,H13-1.2344, 1.2738,1.2718 ,1.2343, 1.2312 ,XPM , NAK80, DVA etc. |

| Special steel | GH2132, GH3030, GH3128, GH4145 ,GH4169 ,GH4080 ,Inconel600 , |

Axle shaft forgings Core advantage

| Company type | Science and Technology innovation board listed company. Stock code :688186 |

| Completed supply chain | Guangda is an leading and integrated steel manufacturer from smelting, forging, heat treatment to precision smart manufacturing . |

| Annual capacity for the forgings | 300,000.00 ton |

| Max length/Diameter | 12m |

| Max weight | 60T |

| Machining | Turning, milling, boring ,grinding, finished machining, gear shaping ,gear hobbing, gear grinding capability. |

| Heat treatment | Normalizing, QT, annealing, carburizing, nitriding with complete heat treatment capacity |

| Surface treatment | High-pressure cleaning, sand blasting and thermal spraying. Complete surface treatment capability. |

| Certificate | PED,DNV, BV, Rina, ISO, GL, ABS, LR etc. |

Axle shaft forgings used for other industry

Axle shaft forgings About Guagnda

Guangda is a specialized in forging research and development,

production, sales, service as one of the comprehensive company. We

could provide rough blank or semi-finishing or finishing parts

focuses on large forging equipment b.We have formed a whole

industrial chain of smelting, casting, machining and surface

treatment, and our technology and cost control are leading in the

world.

As a leading forged shafts manufacturer, we have greater resilience

in our production, which makes our forged steel shaft turnaround

very fast. In addition, due to our distinguished characteristics of

manufacturing and raw materials, the quality of forged steel shafts

that we create are of better quality than shafts machined from

other stock.

Smelting

Forging

Heat treatment

Machining

Inspection

Drive Shaft Horizontal Shaft Prop Shaft Manufacturers Top Quality

Manufcturers