Sunrise Foundry CO.,LTD |

|

Precision Steel Silica Sol Casting for Machinery Part

Product Details

Production Process

About Us

Sunrise Foundry capable of meeting material specifications according to ASTM, SAE, AISI, ACI, DIN, EN, ISO, and GB standards. We have more than 100 different ferrous and non-ferrous alloys with which we cast parts using a complex design criteria. Our dimensionally and geometrically complex investment castings are produced to net shape, minimizing the need for secondary machining. Our top of the line equipment and automation process controls allow for consistent and repeatable tolerances as close as ±0.1 mm. Our castings can also be produced in a wide size range. They be as small as 10 mm long x 10 mm wide x 10 mm high and weigh as little as 0.01 kg, or as much as 1000 mm in length and weigh as much as 100 kg.

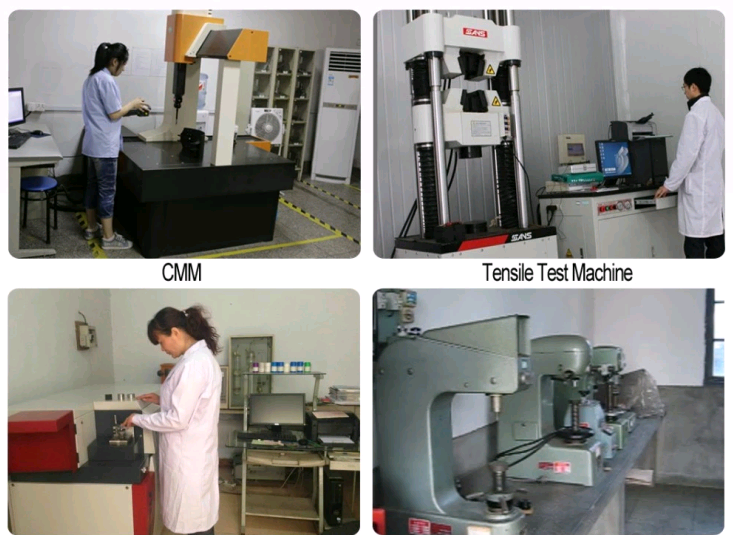

Quality Control

FAQ

A:We will submit the quotation in 24 hours if getting detailed information during working days.In order to quote for you earlier, please provide us the following information together with your inquiry. 1) 3D Step of Files and 2D Drawings 2) Material requirement 3) Surface treatment 4) Quantity (per order/per month/annual) 5) Any special demands or requirements, such as packing, labels,delivery,etc.

A: Generally speaking, we refer to your drawings or original samples, offer some techniques, suggestions and quotations to you. We will produce for you after you agree. we produce the drawing with your approval.

A: The production drawings can be sent in CAD, DXF, STEP, IGES, x_t and other formats, supporting the use of CAD, Soildwork UG ProE and other softwares.