WalthMac Measurement&Control Technology Co., Ltd. |

|

Verified Suppliers

|

|

15mm Plastic Pipe Gravimetric Feeder Controlling Meter Weight High Precision

1. Products Introduction

The Gravimetric Feeder plays a crucial role in the extrusion process, serving as a vital component. Its purpose is to accurately measure the specific quantity of material necessary for each production cycle. By ensuring precise material feeding, this feeder guarantees consistent quality of the end product throughout the entire manufacturing procedure.

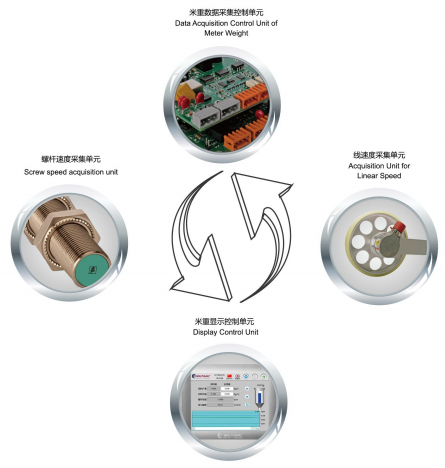

2. Main Structure

| Data Acquisition Control Unit | Collecting data of meter weight in any time |

| Screw Speed Acquisition Unit | Adopting the extruder's screw speed |

| Display Control Unit | Inputting and providing changes of data to oprator to check |

| Acquisition Unit for Linear Speed | Adopting the haul off speed |

3.Features

4.Benefits

5.Applications

The Gravimetric Feeder is ideal for plastic pipe industries,

supporting HDPE, PVC, PE, PPR production.

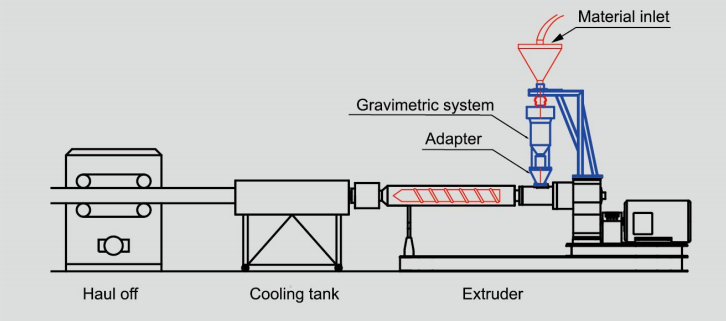

6.Way of installation

Customers are responsible for providing the bracket and adapter for

installing the Gravimetric Feeder on the extruder, as the supplier

is unfamiliar with the production environment.

7.On-sight Application

Our products have been applied to multiple companies both

domestically and internationally, and the manufacturers have given

us many positive feedback.

8.Profile of WalthMac

Mianyang WalthMac Technology Co., Ltd. is a national high-tech

enterprise pursuing "product is art". We have set high standards

for product design, internal management, and quality control.All

our machines have passed the international standard like CE,ISO and

so on.

Achieving a highly intelligent workshop in the future is the trend

of factories in the future, and it is also the parent goal for

Worth to strive for. Worth products focus on helping users achieve

automation throughout the production process, from improving

product quality and saving raw materials to reducing the dependence

on labor throughout the process.

Since extablished in 2009,in these 14 years, we have

participated in plastic and rubber exhibitions in

China and other countries such as

Vietnam,Thailand,America,England etc. We are cooperating with

over 800 companies like DEMUKA,GSM etc, and establishing long-term

cooperative relationships with them.

9.FAQ

Q1. What is your terms of packing?

A: Generally, we pack our plastic granule gravimetric dos in wooden cases.

Q2.What is your items of payment?

A:T/T or some other payment methods.We'll show you the photos of the products and packages before you pay the balance.

Q3.What is your terms of delivery?

A:EXW,FOB,CFR,CIF

Q4.Will you test the machine before exporting?

A:Yes,of course