|

|

[China]

Trade Verify

Address: Building 11, Science and Technology Innovation Base, Mianyang, Sichuan, China

Contact name:Ocean

WalthMac Measurement&Control Technology Co., Ltd. |

|

Verified Suppliers

|

|

PPR Pipe Wall Thickness Ultrasonic Thickness Gauging Machine Contact Measuring Pipe

1. Products Introduction

The Ultrasonic Thickness Gauging Machine is a remarkable

breakthrough! Its 4/8 probes and non-invasive approach guarantee

precise measurements for plastic pipelines. Moreover, its fully

automated design ensures hassle-free operation. This technological

advancement will bring about a significant boost to various

industries.

2. Main Structures

Ultrasonic Thickness Gauging Machine uses 4/8 probes and doesn't require any incisions, yet still manages to provide precise readings for plastic pipes. What's even better is that the entire process is fully automated, making it incredibly user-friendly. This remarkable technological breakthrough is sure to have a positive impact on numerous industries.

3. Technical Parameter

| Applications | Gas pipe,water pipe,car catheter,medical catheter,ocean pipe |

| Application for material | PVC,HDPE,PP,PPR and other plastic pipe |

| Control unit | Walthmac DATASE 1000R ultrasonic measrurement control system |

| Highest measuring precision | 0.001mm |

| Max.outer diameter | 315 mm |

4. Features

5. Advantages

6. Applicable Scope

Our Ultrasonic Thickness Gauging Machine is a highly adaptable tool that brings incredible benefits to various plastic piping systems. Whether for gas, water supply, or other applications, it provides accurate and real-time measurements of thickness, outer diameter, eccentricity, and roundness, ensuring that every inch of your pipes meets production standards. With this fantastic technology, you can have confidence that every pipe will be crafted precisely to your specifications, resulting in top-quality products.

7.The Installation

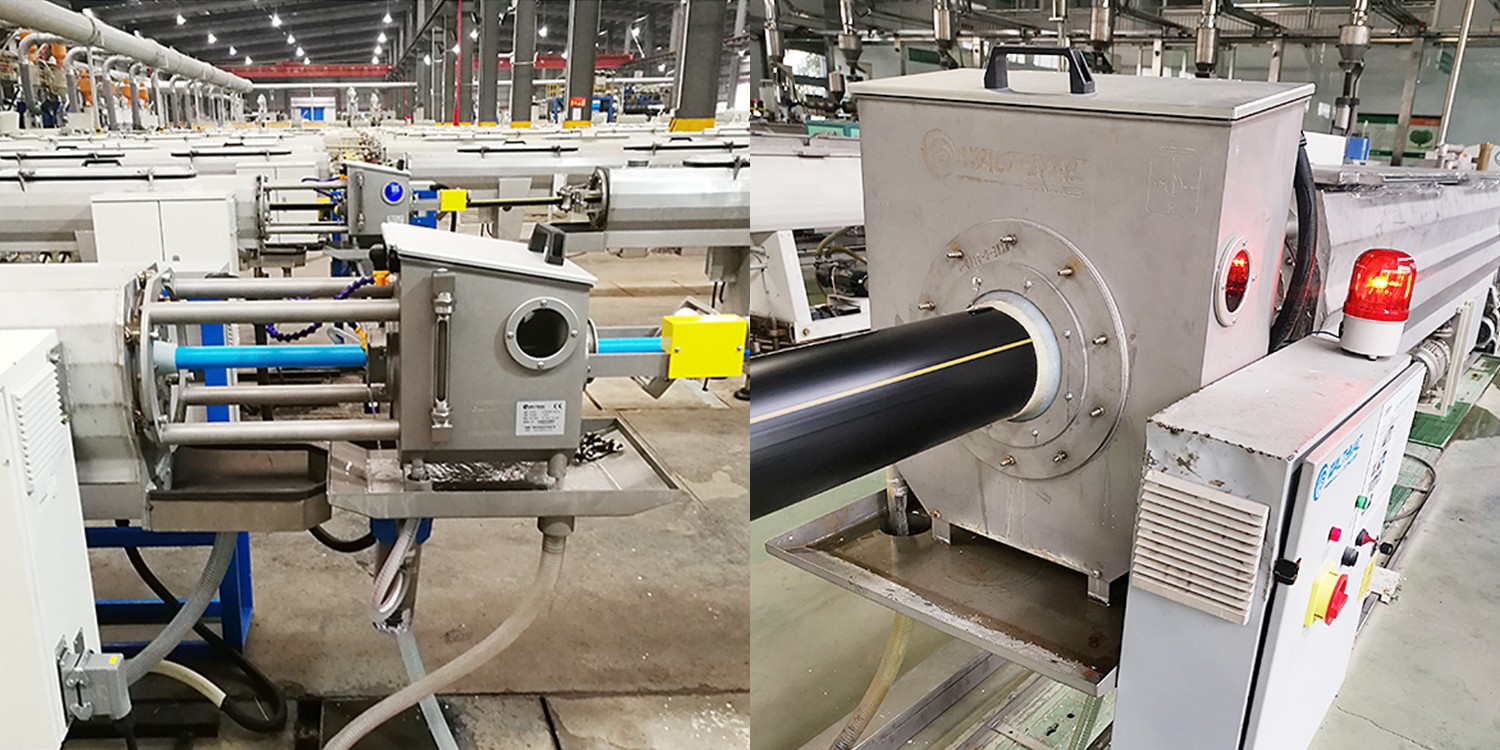

Once the plastic pipe is cooled by the vacuum cooling tank, a scanning box is used to measure its thickness and detect any defects using ultrasound.

8.On-sight Application

We find some applications using on the factories which sent from our long-term partners.

9.About WALTHMAC

Mianyang WalthMac Technology Co., Ltd. is a national high-tech enterprise pursuing "product is art". We have set high standards for product design, internal management, and quality control.

Achieving a highly intelligent workshop in the future is the trend of factories in the future, and it is also the parent goal for Worth to strive for. Worth products focus on helping users achieve automation throughout the production process, from improving product quality and saving raw materials to reducing the dependence on labor throughout the process.

Since its establishment for 14 years, we have participated in rubber and plastic exhibitions in domestic and abroad every year, cooperating with over 800 companies like DEMUKA,GSM etc, and establishing long-term cooperative relationships with them.