GUANGDONG TOUPACK INTELLIGENT EQUIPMENT CO., LTD |

|

Verified Suppliers

|

|

High Speed Stainless Steel Check Weigher Machine Waterproof CW300

Check Weigher Features:

1. Intelligent design, automatic parameter adjustment and easy

operation.

2. Material dense alarm, automatic generate column production report.

3. Conveyor structure adopts detachable design for easy disassembly and cleaning.

4. PLC control system, standard industrial control screen, easy to expand other value-added applications, such as multi-stage weight sorting, weight feedback, etc.

Application:

It is suitable for testing whether the weight of single /

single package / single box products is qualified. It is widely

used in electronics, pharmaceutical, food, beverage, health

products, daily chemicals, light industry, agricultural and

sideline products and other industries. At the same time, it is

applicable to the detection of missing parts in the whole box; Such

as: lack of bottles, boxes, numbers, pieces, bags, cans, etc.

Checkweigher Specifications:

| Model | TYA-CW300 | TYA-CW400 | TYA-CW500 |

| Weighing Range | 10kg | 20kg | 30kg |

| Weighing Accuracy | ±2g | ±5g | ±10g |

| Weighing Resolution | 0.1g | 0.1g | 0.1g |

| Max Speed | 65P/M | 50 P/M | 30P/M |

| Belt Width | 300mm | 400mm | 500mm |

| Weighing Belt Length | 450mm | 570mm | 1050mm |

| Infeed/Outfeed Belt Lenght | 450/800mm | 570mm/Roller 930mm | Roller Rejector 800mm |

| Power Supply | AC220V ±10%/1P/0.5KW | AC220V ±10%/1P/0.5KW | AC220V ±10%/1P/0.5KW |

| Control System | High speed A/D sampling controller | High speed A/D sampling controller | High speed A/D sampling controller |

| Pre-set Prod. No. | 99 | 99 | 99 |

| Belt Height | 750±50mm | 750±50mm | 750±50mm |

| Optional Rejector | Air blower | pusher | Pusher |

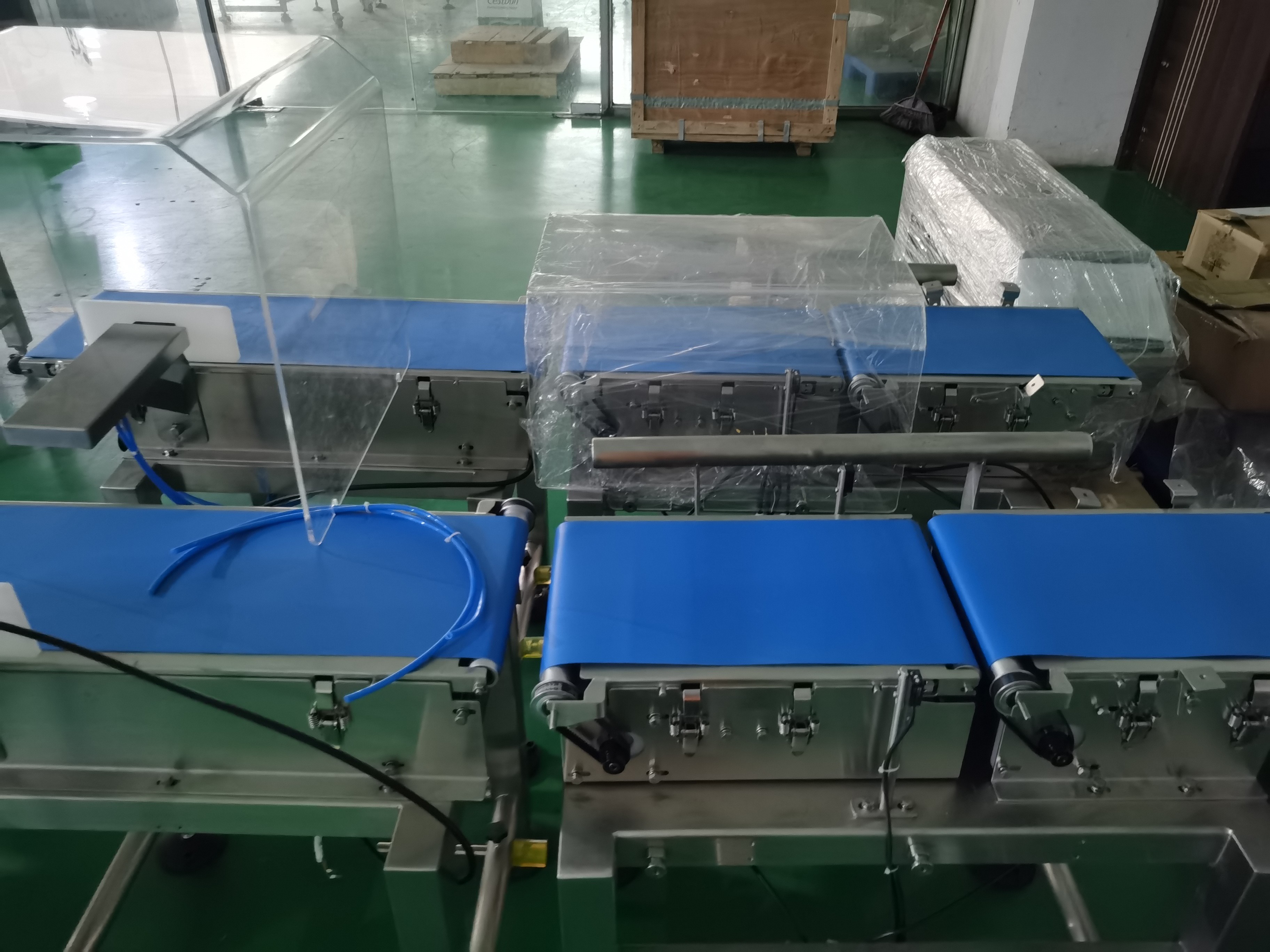

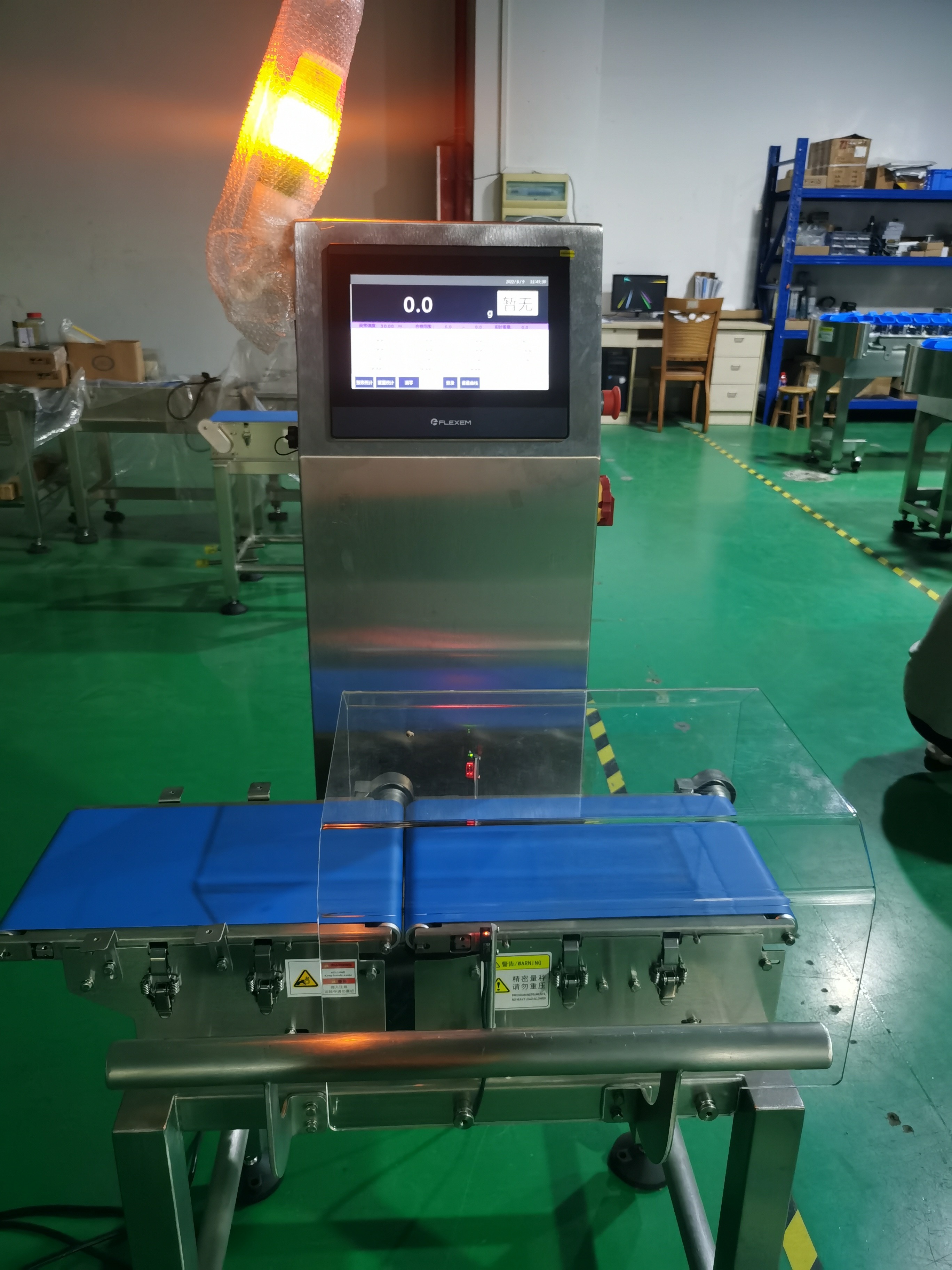

High Speed Stainless Steel Check Weigher Machine Waterproof Automatic

Photos:

1. What is Checkweigher?

A checkweigher is a high-precision weight measuring instrument. It

is designed to check the weight of individual products during the

manufacturing process on production lines.

Checkweighers are predominatly used as part of a manufacturing

quality control programme. Their weighing results are required to

ensure that manufacturing sites comply with local packaging laws

and regulations during production.

A checkweigher ensures that every product leaving a production line is the right weight. They are key to ensuring manufacturers deliver quality products that promote high levels of customer satisfaction. Selling underweight products can result in companies being fined or subject to other penalties. Overweight products generate unnecessary and expensive product giveaway. Checkweighers can be used in near to all industries as part of an effective quality assurance system. These include: Food, Pharmaceuticals, Cosmetics Beverages, Transport/logistics, Chemicals, Automotive, Metal manufacture and fabrication industries, etc.

2. What are the differences between static and dynamic checkweighers?

The main differences between static and dynamic checkweighers are:

a. Static checkweighers measure the weight of products that stand

still. Dynamic checkweighers weigh products in motion.

b. Static checkweighers are used for manual weighing of products or

for sample spot-checking. Dynamic checkweighers automatically check

100 % of the products produced

c. Static checkweighing is a labour intensive process. It requires

manual product weighing, recording of the result and then product

removal for the next weighing procedure. Dynamic checkweighing is

entirely automatic. Products are weighed as they pass along a

production line, with off-weight products rejected from the

production line by automated removal devices such as pneumatic

pusher arms or air-jets.

3. Reasons for a Checkweigher in Your Production?

Checkweighers have long been a key element of production operations, as they are capable of far more than just weighing, and can actually optimise your whole production process. Benefits of a checkweigher include:

1). avoid costly fines with 100% weight inspection

2). keep fillers operating in synchronisation

3.) save material, so as to produce more products and profits

4). mprove production processes and equipment efficiency

5). save labor and personnel costs

6). reduce false rejects and rework

7). maintain the identity of your brand

4.Why choose us

1.Over 12 years weighing and packing machine design & manufacturing experience

2.Over 60 countries customers choices

3.Professional team with passion and diligence

4.All-in-one stand service

After-sale services:

1. Manual / Videos of machine installation, adjusting, maintenance are available for you.

2. If any problems happened, telecom or online face to face communication available 24 hours.

3. Engineers & technician Engineer available to serve machines for your countries.

4. The machine will have 1 year warranty of machine.