Henan Genghong Industrial Co., Ltd. |

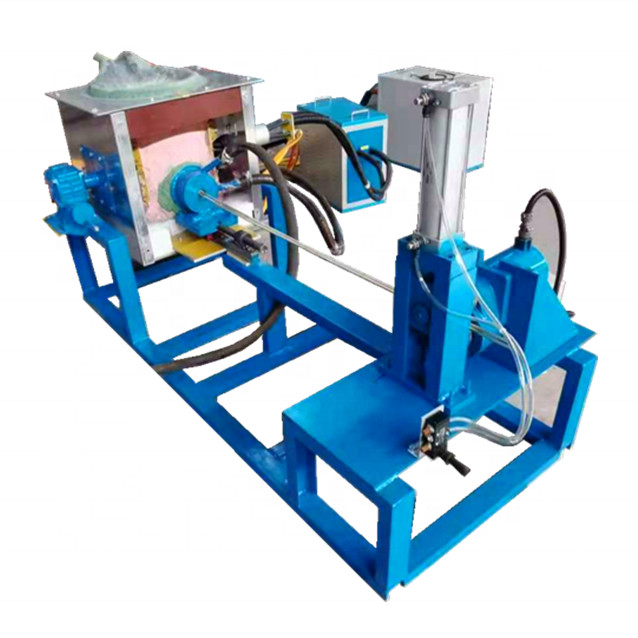

Copper Alloy Horizontal Copper Rod Continuous Casting Machine

Product profile

The aluminum ingot casting machine includes a grooved mold base, which is characterized in that the mold base is composed of a fixed mold base and a movable mold base. The fixed mold base is provided with a column, and the column is provided with a column. The rotating arm is provided with a lifting extrusion head, and the movable mold base is arranged on the sliding part.

The aluminum ingot casting machine solves the problem of loose, easy delamination and falling off of aluminum clad iron particles, effectively improves the working efficiency of aluminum ingot casting and iron particle coating demoulding, improves product quality, and fully meets the requirements Requirements for ingot quality. The casting machine has a simple structure, is light and quick to operate, does not occupy space, and is convenient to move, which can effectively reduce the labor intensity of workers and improve the working environment.

Aluminum ingot continuous casting machine: horizontal continuous casting machine, water bath cooling conveyor, rectangular coordinate robot palletizer, first-level finished product conveyor, electronic platform scale, and second-level finished product conveyor are placed in sequence. A guide rail is installed at the tail side of the first-level finished product conveyor, which is parallel to the aluminum ingot conveying guide rail, and a guide rail forklift is installed on the guide rail. The aluminum ingot is produced by a horizontal casting machine and then cooled and formed by a water bath cooling conveyor. Then, the rectangular coordinate robot palletizer palletizes the cooled and formed aluminum ingots and transfers them to the first-level finished product conveyor. The rail forklift transports the stacked aluminum ingots to the electronic platform scale for weighing, and then directly transports the stacked aluminum ingots to the warehouse by the secondary finished product conveyor.