|

|

[China]

Trade Verify

Address: No. 2319, Building 2, Dongfang Furong Garden, No. 582 Yuanda 1st Road, Hehuayuan Street,Furong District, Changsha city, Hunan, China.

Contact name:Julia Wang

Hunan Dinghan New Material Technology Co., LTD |

|

Verified Suppliers

|

|

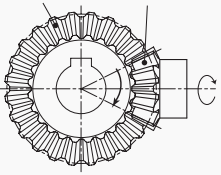

Products: Bevel Gear Straight Gear With 90 Degree, Quenching And CNC Precision Turning

1. Straight bevel gears are commonly used in a variety of mechanical and automotive applications such as differentials, transmissions, and steering systems. They are particularly suitable for applications requiring high speed and heavy loads.

2. 90 degree straight bevel gear is an efficient, durable and reliable mechanical component widely used in various industrial and automotive fields.

Advantages of straight bevel gear: high strength, large load-bearing capacity, long service life, high efficiency, etc.

1. High efficiency: Since the tooth surface is designed as a

straight line, straight bevel teeth can provide high-efficiency

power transmission.

2. Sturdy and durable: The straight tooth surface and precise

manufacturing process of straight bevel teeth make them highly

durable.

3. Reduced Noise: Straight bevel teeth produce less noise during

operation than helical or helical teeth.

Disadvantages of straight bevel gear:

It has higher installation requirements.

Straight bevel gear parameter table:

| Products | Straight Bevel Gear With 90 Degree, Quenching And CNC Precision Turning |

| Service | Customized |

| Shape | Bevel gear |

| Gear Teeth manufacturing | Cutting/Grinding/hobbing |

| Module (M) | ≤4 |

| Teeth Accuracy Grade | ISO 6-7 Grade |

| Heat Treatment | Carburization and quenching/Carbonitriding/High frequency/Quenched and tempered...... |

| Pressure angle | 20 / 25 degree |

| Hardness | Hardened |

Direction of motion:

In a single-stage gear mechanism with external gear meshing, the driving gear and the driven gear rotate in opposite directions.

Pictures display: