Suzhou Ephood Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

VMM Model Elektrogas Multiple Safety Solenoid Valve For Gas Regulating Trains

Elektrogas VMM type valve is a combination of two valves in an only compact and versatile valve housing. The first valve is a fast opening safety solenoid valve. The second valve may be a fast opening or a slow opening solenoid valve to adjust the gas flow, with a first adjustable fast stroke and a second adjustable slow stroke. It is possible connect a third by-pass / pilot valve, which performs by driver stage or to obtain a second fast (slow) stroke or both. This type of device is suitable for gas and air blocking and adjusting controls in atmospheric burners or fan-assisted burners (with one or two stage operation), in industrial kilns and in all gas equipments which use regulating trains.

This type of device is suitable for air or gas blocking and releasing controls (with one or twostages operation), required in gas power burners, atmospheric gas boiler, industrial kilns andothers gas consuming appliances.

Technical Specifications

| Connections | ANSI-ASME B1.20 from 3/4"NPT to 2" NPT Flanged PN16,DN40 to DN80 or ANSI-ASA-ASME B16.5 class 150 from 2” to 3” |

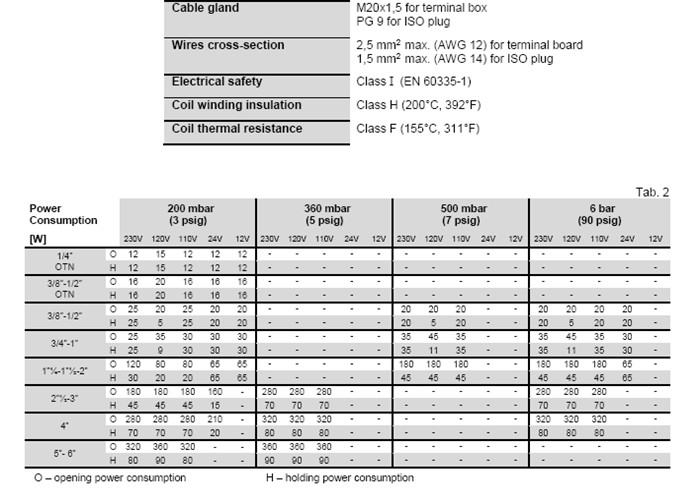

| Voltage Ratings | 230 VAC 50/60 Hz 120 VAC 50/60 Hz 110 VAC 50/60 Hz 24 VAC/DC |

| Max. Operating Pressure | 200 mbar (3 psig) 500 mbar (7 psig) |

| Body Test Pressure | 1 bar (15 psig) |

| Closing Time | < 1 second |

| Opening Time | Adjustable |

| Gas strainer | 600 μm (0.02 in),metal mesh |

| Enclosure | IP54 (NEMA 3) optional IP65 with cable (NEMA 4) |

Description

The valves are made of aluminum alloy die-cast, with a range for

inlet/outlet connections fromDN20 (3/4") up to DN80 (3").

Sealings are made of NBR-based rubber certified for use with gas

(EN 549).

Pipe connections meet group 2 and backpressure sealing is compliant

with class A, accordingto EN161 requirements.

A third valve with capacity of DN15 or DN25 can be fitted to

by-pass the second one and have alow fire stage or a second outlet

for pilot bumer (pilot execution).

Suitable for use with air and non-aggressive gases included in the

1, 2 and 3 families (EN 437).Special versions for aggressive gases

.

The whole range can be provided in Ex-proof execution, for use in

Zones 2 and 22, according to2014/34/EU Directive (ATEX).

The valve is open only when energized: if, for any reason, power

supply goes down, the valvecloses immediately (intrinsic safe).

Suitable for heavy-duty cycle operation and qualified for

continuous service (100% ED).

Equipped with flow rate adjustment.

An incorporated fine mesh filter protects the valve seat and disc

as well as downstreamcomponents and prevents dirty contamination.

Provided with bilateral pressure ports on two sides in all pressure

chambers, to connectmanometers, pressure switches, leakage tester

or other gas equipments.

The coils are provided with terminal box or with ISO 4400 plug.

Both systems are provided withsuitable cable gland to avoid water

and dirty contamination.

The normally open vent valve VMRNA can be integrated in VMM from

1"V4 to 3"; dimensionsand piping are the same of third pilot valve.

See VMRNA datasheet for other details.

All components are designed to withstand any mechanical, chemical

and thermal conditionoccurring during typical service. Effective

impregnation and surface treatments have been usedto improve

mechanical sturdiness, sealing and resistance to corrosion of the

components.

Valves are 100% tested by computerized testing machineries and are

fully warranted.

Function and Application

The VMM type valve is a safety shutting device using auxiliary

power supply.

The first valve (A) is a fast opening safety solenoid valve. When

it is de-energized, the springpushes on the seal disc, keeping the

gas passage closed. Now, the inlet chamber is under thegas line

pressure, and it forces on the disc too, improving the seal.

When the coil is powered the valve opens rapidly, against the

strength of the spring and gaspressure.

If the power supply is shut off, the valve rapidly closes,

interrupting the gas flow.

Equally, the second valve (B) may be a fast opening or a slow

opening solenoid valve to adjustthe gas flow, with a first

adjustable fast stroke and a second adjustable slow stroke.

It is possible to connect a third by-pass valve (C), which works as

low fire stage or to obtain asecond fast (slow) stroke or both.