Wuxi Wilke Metal Materials Co., Ltd. |

|

Verified Suppliers

|

|

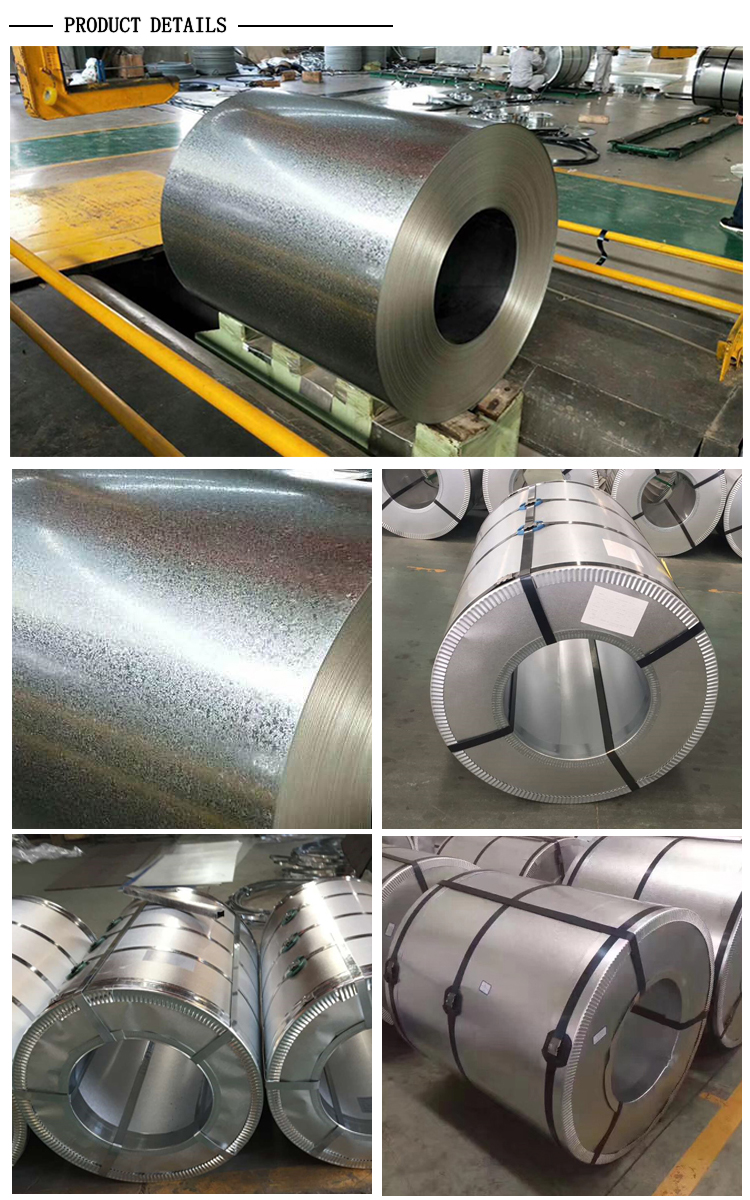

Zinc Hot Dipped Cold Rolled Galvanized Steel Coil with Gauge 22 24 28 30

Galvanized sheet coils, literally, are galvanized sheets in coils. The galvanized coil is the predecessor of the galvanized sheet.

The galvanized coil is cut into sheets by equipment. The galvanized coil is placed on the shelf with a forklift or aerial crane, and then transferred, flattened and cut by the equipment. The widths are all standard widths of one meter, one meter twenty-five, and one meter five, and the length is optional.

Galvanized Steel Coil Features:

1. The galvanized steel coil is widely used in various environments and has a long anti-corrosion life. The anti-corrosion life is different in different environments.

The processing cost is low, and the anti-corrosion cost of galvanized steel coil is lower than other paint coatings.

2. Durable, in the suburban environment, the standard galvanized anti-corrosion layer does not need to be repaired and can be maintained for more than 50 years. In cities or offshore areas, the standard galvanized anti-corrosion coating can be maintained for 20 years without repairs.

Good reliability. The galvanized layer and the steel are metallurgically combined and become part of the rigid surface, so the durability of the coating is relatively reliable.

3. The coating has strong toughness, and the zinc coating forms a special metallurgical structure, which can withstand mechanical damage during transportation and use.

4. Integrity protection: All parts of the plated parts can be galvanized, even in recesses, sharp corners and hidden places can be fully protected.

It saves time and effort. The galvanizing construction speed is faster than other coating construction methods, which can avoid the time required for on-site painting after installation.

Product Description:

| Specifications | Zinc Coated Hot Dipped Galvanized Steel Coil | ||

| Application | Commercial Quality | ||

| Usage | Furniture, Computer Case, Electronic Parts, Electrical Equipment | ||

| Type of Surface Treatment | Normal (uneven) spangle/ Skinpassed spangle/ Regular spangle / Minimized spangles | ||

| Available Size | Thickness: 0.12-4mm | ||

| Width: 600-2000mm | |||

| Coating Weight: 20-275g/m | |||

| Max. Coil Weight: ≦ 20 MT | |||

| MOQ | 3 tons per color/ size | ||

| Supply Ability | 5000t/month | ||

| Delivery Time | Within 15 days after receiving the pre-payment. | ||

| Export Packing | Standard Export Seaworthy Package. | ||

| Payment Terms | L/C at sight, T/T or Negotiable. | ||

Equivalent Material

| Grade | Euronorm | China GB | Japanese JIS | US ASTM | German |

| EN10130-2006 | GBT 2518-2008 | JIS: G3302-2005 | ASTM A653M | Q/SGZGS 324.3-2011 | |

| DX51D+Z | DC01 | DC01 | SPCC | CS TypeC | St12 |

| DX52D+Z | DC03 | DC03 | SPCD | CS TypeA TypeB | St13 |

| DX53D+Z | DC03 | DC03 | SPCE | CS TypeA TypeB | St14 |

| DX54D+Z | DC06 | DC06 | SPCG | EDDS | St16 |

Standard Specification

| Thickness | 0.12~4mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 1000-6000 or Since the custom |

| Surface | Normal (uneven) spangle/ Skinpassed spangle/ Regular spangle / Minimized spangles |

| Form | coils, Foils, Rolls, Plain coils, Shim coils, Perforated coils,

Chequered coils, Strips, Flats, Blank (Circle), Ring (Flange) etc. |

Metal Content

| Grade | C | Mn | P | S |

| DX51D+Z | – | – | – | – |

| 0.2 | 0.25 | 0.02 | 0.02 | |

| DX52D+Z | – | – | – | – |

| 0.1 | 0.45 | 0.03 | 0.03 | |

| DX53D+Z | – | – | – | – |

| 0.12 | 0.5 | 0.04 | 0.04 | |

| DX54D+Z | – | – | – | – |

| 0.15 | 0.6 | 0.1 | 0.05 |

Hot-dip galvanized layer formation process

The formation process of the hot-dip galvanizing layer is the process of forming an iron-zinc alloy between the iron matrix and the outermost pure zinc layer. The iron-zinc alloy layer is formed on the surface of the workpiece during hot-dip coating, which makes the iron and pure zinc layers very close. Good combination, the process can be simply described as when the iron workpiece is immersed in molten zinc, a solid solution of zinc and α iron (body core) is first formed on the interface. This is a crystal formed by dissolving zinc atoms in the base metal iron in a solid state. The two metal atoms are fused, and the attraction between the atoms is relatively small. Therefore, when zinc reaches saturation in the solid solution, the two element atoms of zinc and iron diffuse each other, and the zinc atoms that have diffused (or infiltrated) into the iron matrix migrate in the matrix lattice, and gradually form an alloy with iron, and diffuse The iron and zinc in the molten zinc form an intermetallic compound FeZn13, which sinks into the bottom of the hot-dip galvanizing pot, which is called zinc dross. When the workpiece is removed from the zinc immersion solution, a pure zinc layer is formed on the surface, which is a hexagonal crystal. Its iron content is not more than 0.003%.

Packing & Delivery:

FAQ:

Q1. What are your company's main products?

A1: Our main products are Galvanized Steel Coil, Galvanized Steel

Sheet, PPGI Steel Sheet, GI Roofing Sheet, PPGI Steel Coil etc.

Q2. How do you control quality?

A2: Mill Test Certification is supplied with shipment, Third Party

Inspection is available. and we also get ISO, SGS, Alibaba

Verified.

Q3. What are the advantages of your company?

A3: We have specialized in the steel business for years, so we have

mature production technology, stable capacity, more competitive

prices,

we are dedicated to strict quality control and thoughtful customer

service.

Q4. Can you provide a sample?

A4: We can provide the same samples in stock for free, as long as

you contact us.

About us:

Wuxi Wilke Metal Materials Co., Ltd. is a leading supplier of high-quality galvanized steel materials. Established in 2012 in Wuxi, China, the company has quickly become a reputable and reliable supplier of metal materials to customers around the world.

At Wuxi Wilke Metal Materials Co., Ltd., we pride ourselves on providing superior quality products that meet international standards. Our products are sourced from reputable manufacturers who have a proven track record of delivering high-quality materials. We have established long-term relationships with these manufacturers, which enables us to offer our customers competitive prices and consistent product quality.