Shanghai Gofun Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Popular Apple Juice Processing Line For Long-Shelf Life Juice Complete Plant

Description

Shanghai Gofun machinery company, a professional apple and pear

processing line manufacturer and exporter in China. We can

provide turnkey solutions and technical support for the apple and

pear processing lines with all kinds of end products from fresh

apple and pear.

Apple and pear processing lines can produce from fresh apple and pear to different kinds of the final products. The processing line includes ①washing, ②sorting, ③crushing, ④juice extracting, ⑤preheating, ⑥evaporating, ⑦sterilizing, ⑧aseptic bag in drum filling or BIB filling, and other processing ways. The fresh apple, and pear can be processed fruit pulper, puree, juice, jam, beverage and etc.

The entire line is designed for apple/pear juice according to

international quality standards. Feel free to contact us to design

the best solution for your company.

Applications

Shanghai Gofun machinery company offers all kinds of apple and pear

processing lines. The extraction way can be belt press type,

pneumatic press type, or others. The package can be aseptic bags,

sachet, stand-up pouch, metal can, PP container, PET bottle, glass

bottle, gable top, etc. Shanghai Gofun machinery company can help

you produce all kinds of apple and pear products.

The capacity of the apple/pear processing line is varied from 20

T/day to 1500 T/day. The line can also be shared for processing

other fruits with similar characteristics. The belt press is

specially used and the whole extraction lasts only 1~2 minutes,

which allows maintaining products freshness. The extraction rate is

especially no less than 75%. A complete set of R.O. water treatment

systems can be provided if needed. The end products are of good

taste and nice color. A multi-effect evaporator can be chosen for

different capacities. Either a fully automatic line or a

semi-automatic line can be chosen according to the cost.

Related Equipment

Washing & Sorting machine: Different types of washing machines can be offered: bubble washing machine, spray washing machine, brushing washing machine, etc., type and model are customized according to the customer requirements and layout.

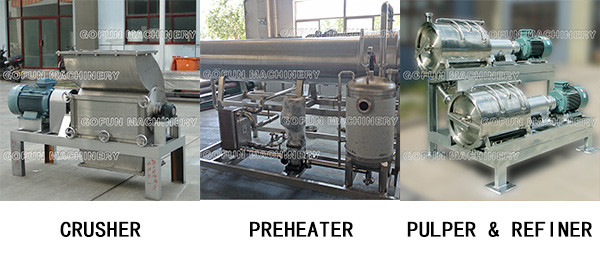

Crushing machine: GFM-FC series crusher has the most advanced working principle, higher accuracy of manufacture, and best crushing functions. It is mainly used for crushing many kinds of fruits or vegetables, for example, tomato, apple, pear, strawberry, celery, fiddlehead, etc. it can crush the raw materials into small particles, and it will be better for the next processing section. The machine is composed of a feed hopper, side cover, frame, principal axis, bearing block, motor, motor structure, outlet hopper, etc.

Belt-press type extractor: The belt press juicer extractor is a highly efficient juice extracting equipment in fruit and vegetable juice/pulper production and is a key equipment to the juice yield. The belt-press extractor is widely used in the apple, pear, berries, and other fruits/vegetables juice production industry. The equipment adopts multi-stage bends to increase the filter area, and the pneumatic balloon will provide huge pressure for the belt filter to make sure the filtering effect. With this extractor juice rate can reach more than 70%. At the same time, it is a kind of juice equipment that has energy conservation and a high degree of automation, automatic front-rear, continuous work, strong commonality, filter, filter cake moisture content is low, the advantages of convenient operation and maintenance with a higher rate of juice. Using this equipment can make the fruit juice yield increase 20-35% and greatly reduce the production cost, improve the production efficiency.

UHT Sterilizer: The sterilizing temperature and holding time is adjustable. With this machine, the fruit or vegetable juice/paste/pulper can be heated to a very high temperature around 115℃, held for 30s, and then cooled to ambient temperature immediately. UHT sterilizer can protect the taste and nutrients of fruits or vegetables as much as possible.

Aseptic filling machine: The aseptic filling machine works together with the UHTtubular type

sterilizer. It’s a closed cycle. Before production, the cycle will

be fully sterilized to make sure of the aseptic environment. And

the filling cavity is also protected by steam to make sure the

filling environment is also aseptic. Juice/pulper/paste

would be filled in aseptic bags to improve the shelf

life.

Our Strength

Pre-Sales Service:

1. Technical support

2. Marketing suggestion

3. Final packing suggestion and design

4. Factory building and design

After-Sales Service:

1. Oversea technical support

2. Oversea equipment maintenance

3. English speaking engineers available to provide technical support