Shanghai Gofun Machinery Co., Ltd. |

|

Verified Suppliers

|

|

CE Certified Orange Juice Processing Machine Production Plant 20 - 1500 T/Day

Description

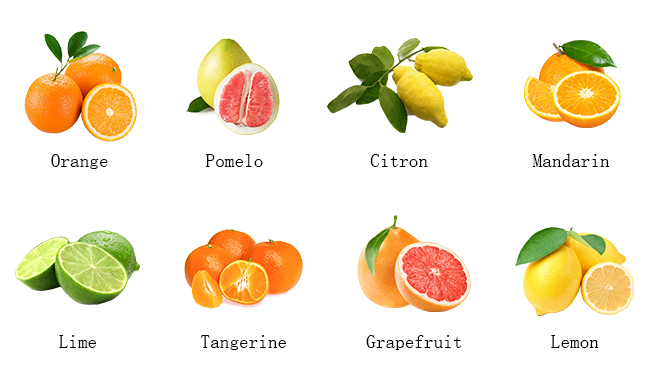

Citrus processing line can produce from fresh citrus to different kinds of final product. The raw material can be all kinds of citrus fruits, including orange, mandarin, lemon, grapefruit, etc. And the final product can be clear juice, cloudy juice, juice brink, juice concentrate, oil, etc. For the package, it can be aseptic bags, sachet, stand-up pouch, metal can, PP container, PET bottle, glass bottle, gable top, etc. All kinds of citrus product are very popular all over the world.

Shanghai Gofun machinery company, a professional citrus processing line manufacturer and exporter in China. Which can provide turnkey solution and technical support for citrus processing line with different kinds of end products from citrus and all kinds of package.

CITRUS FAMILY

END PRODUCTS

Our Advantages

The citrus processing line from Shanghai Gofun machinery company is

running with high effective, water saving, high extracting rate,

safety quality control for final product, safety control for

operators, etc.

Gofun Machinery is committed to building a world-renowned enterprise in the world's food, fruit and vegetable, dairy, beverage equipment production line turnkey project overall solution. The core components of the pomegranate processing production line are basically imported or domestic first-line brands: so the quality and equipment stability is relatively high, and the mechanical after-sales service has always been better in the industry.

1.The motor of Gofun’s processing machine is basically ABB, Siemens

and Jiangsu Dazhong;

2.The water pump is from Nanfang and the centrifugal pump is from

Yuanan;

3.Electrical cabinet and PLC control system: Siemens PLC touch

screen, switch and AC contactor electrical protection is Schneider,

intermediate relays are Honeywell;

4.The 304 pipes we use for the pipeline is from Yuan'an, the cables are all good cables.

Flowchart

Citrus Juice Processing Line

CLOUDY JUICE: FRESH CITRUS ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒

EXTRACTING ⇒ PULPER & REFINER ⇒ HPP STERILIZING ⇒ ASEPTIC

FILLING ⇒ STORAGE OR BLENDING

CLEAR JUICE: FRESH CITRUS ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ EXTRACTING ⇒ PULPER

& REFINER ⇒ ENZYMATIC HYDROLYSIS & FILTRATION SYSTEM ⇒ HPP STERILIZING ⇒ ASEPTIC FILLING ⇒ STORAGE OR BLENDING

Related Machine

Kiwifruit is a popular fruit in many regions around the world. Gofun can supply complete Kiwifruit processing line for the production of juice, as well as puree. In the last decades we've installed lots of juice production lines in many countries.

1. washing and sorting machine

Different types of washing machine can be offered: bubble washing machine, spray washing machine, brushing washing machine, and etc., type and model can be customized according to customers’ requirements.

2. Pulper & refiner

This machine is Used for many different kinds of fruits that includes the tomato, peach, apricot, mango, apple and etc. to separate the fruit pulp and slag by pulping.

3. Sterilizer

The sterilizing temperature and holding time is adjustable. With this machine, the fruit or vegetable juice/paste/pulper can be heated to a very high temperature around 115℃, held for 30s and then cooled to ambient temperature immediately. UHT sterilizer can protect the taste and nutrients of fruits or vegetables as much as possible.

4. Aseptic filler

Company Information

Gofun Company provides the turn-key solution for not only the tomato paste production line but also the processing and packaging lines for apple, pear, peach, mango, and apricot and other fruits & vegetables, and has received wide spread praises from customers in both the domestic and overseas markets. The machines have already been exported to all over the world including the Asian countries, African countries, South American countries and even European and American countries. Gofun Company aim to create the outstanding food machinery and contribute to the world's agricultural industry. We sincerely committed ourselves to a brilliant prospect and mutual benefit relationship with all of the people and friends from Worldwide!

| Business Type | Manufacturer | Country | China |

| Main Products | Turn Key Solution for Fruit & Vegetable Processing and Packaging Complete Line | Capacity | 30 sets per year (whole line) |

| Established Year | 2009 | Main Market | Africa, South Ameria, Asia, Europe |

Our Services

1. Technical support

2. Marketing suggestion

3. Final packing suggestion and design

4. Factory building and design

After-Sales Service

1. Oversea technical support

2. Oversea equipment maintenance

3. English speaking engineers available to provide technique support

Customer Show