Shanghai Gofun Machinery Co., Ltd. |

|

Verified Suppliers

|

|

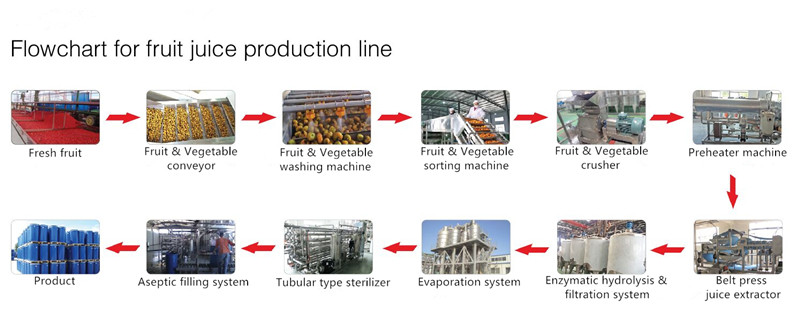

Gofun Co., Ltd. offers comprehensive turnkey solutions for various fruit and vegetable processing and packaging lines, encompassing not only tomato paste production but also apple, pear, peach, mango, apricot, and more. These solutions have garnered high praise from customers in both domestic and international markets. Our machines are exported worldwide, including Asian countries, African countries, South American countries, and even Europe and America.

At Gofun, our objective is to develop exceptional food machinery and contribute to the advancement of global agriculture. We wholeheartedly strive to foster bright prospects and establish mutually beneficial relationships with people and friends from all corners of the world.

The sterilization temperature and holding time of our machine are fully customizable. Using our equipment, fruit and vegetable juices, pulp, and fruit purees can be heated to a high temperature of approximately 115°C and held for 30 seconds before being rapidly cooled to ambient temperature. Our UHT sterilizers are designed to preserve the flavor and nutritional content of fruits and vegetables to the greatest extent possible.

| Model | GFM10D1000 | GFM10D3000 | GFM10D5000 | GFM10D8000 |

| capacity(L/H) | 1000 | 3000 | 5000 | 8000 |

| power(KW) | 15 | 25 | 40 | 72 |

| System design pressure(MPa) | 4 | 5 | 10 | 16 |

| Steam consumption(kg/h) | 250 | 750 | 1300 | 2000 |

| Compressed air consumption(m³/h) | 12 | 12 | 12 | 12 |

| Cooling water consumption(t/h) | 15 | 25 | 45 | 70 |

| Material sterilization temperature(℃) | 90-125 | 90-125 | 90-125 | 90-125 |

| Sterilization time(s) | 120-180 | 120-180 | 120-180 | 120-180 |

| Feed temperature(℃) | 60-68 | 60-68 | 60-68 | 60-68 |

| Discharge temperature(℃) | ≤40 | ≤40 | ≤40 | ≤40 |

| Exterior dimension(mm) | 9500X2100X3000 | 1100X2100X3000 | 1200X2400X3000 | 1300X2500X3000 |

Shanghai Gofun Machinery Co., Ltd. offers a range of sterilization processing lines to meet diverse needs. Our sterilization methods include tube sterilizers, tube-in-tube sterilizers, and more. We provide various packaging options such as aseptic bags, pouches, stand-up pouches, metal cans, PP containers, PET bottles, glass bottles, and roof covers. With our expertise, we can assist in producing a wide array of fruit and vegetable products.

Our fruit and vegetable sterilizer processing lines have a production capacity ranging from 20 tons/day to 1500 tons/day. These lines can also be utilized for processing other fruits with similar characteristics, allowing for shared usage. Notably, our tube-in-tube sterilizer is employed, enabling a short sterilization time as brief as 30 seconds while maintaining product freshness. With a sterilization rate exceeding 75%, the final product boasts excellent taste and appealing color. We offer a selection of multi-effect evaporators with different capacities. Customers can choose between fully automatic or semi-automatic lines based on cost considerations.

| Main configuration of the system | ||

| No. | Item | Brand |

| 1 | PLC | Siemens |

| 2 | Human Machine Interface | Siemens |

| 3 | Steam Reducing Valve | Spirax Sarco |

| 4 | Steam Regulating Valve | Spirax Sarco |

| 5 | Steam Trap Valve | Spirax Sarco |

| 6 | Electric Elements | Schneider |

| 7 | Transducer | Japan Fujifilm |

| 8 | Temperature paperless recorder | YOKOGAWA |

| 9 | Breaker | Schneider |

| 10 | Central relay | Omron |

Our machine employs contactless heat exchange in closed systems for both the material and heat transfer medium, ensuring the utmost hygiene and safety of the processed materials. The sterilization time is optimized to avoid damaging the nutritional components of the materials.

Constructed with food-grade stainless steel, our equipment complies with national safety and hygiene requirements for beverage and food processing. It boasts excellent heat transfer performance, high heat recovery rate, and low energy consumption.

The key control components, valve parts, and support parts are sourced from reputable suppliers and are imported, ensuring a long service life for the machine. PLC control is adopted, enabling automatic regulation of heating temperature, hot water temperature, and steam flow for each section of the material. An automatic feeding system is also integrated to guarantee effective sterilization of the materials.

This equipment is characterized by its simple structure, easy cleaning, user-friendly operation, and low maintenance cost.

1. A high-tech enterprise with its own professional team and manufacturing plant.

2.The advanced technology is the top level in Japan and overseas, and we have acquired a technology patent.

3. Located in the national key high-tech area, only 30 minutes drive from the airport.

4. Strict quality inspection, all products are advanced and durable, enjoying high reputation.

5. Excellent pre-sales and after-sales service.