Hubei Yue Zhong Xin Fibreglass Manufacturing Co., Ltd. |

|

Verified Suppliers

|

|

High Thermal Resistant FRP Pultruded Air Duct Pipe for Environment Protection

Product Description

FRP (Fiber Reinforced Polymer) pultruded tubes, also known as fiberglass pultruded tubes, are structural members made through the pultrusion process. Pultrusion is a manufacturing technique that involves pulling continuous fibers, usually glass fibers, through a resin bath and then through a heated die. The resulting composite material exhibits high strength and stiffness properties.

FRP pultruded tubes are composed of a matrix material, typically polyester, vinyl ester, or epoxy resin, reinforced with continuous glass fibers. The fibers provide reinforcement, while the resin acts as a binding agent, holding the fibers together and protecting them from environmental factors.

The pultrusion process allows for the creation of tubes with consistent cross-sectional shapes and dimensions. The tubes can have various diameters, wall thicknesses, and lengths, depending on the specific application requirements. The pultruded tubes can also be customized to have different surface finishes, such as smooth or textured.

The advantages of FRP pultruded tubes include:

High Strength-to-Weight Ratio: FRP pultruded tubes have excellent strength-to-weight ratios, meaning they offer high strength and stiffness while being lightweight. This makes them suitable for applications where weight reduction is a consideration without compromising structural integrity.

Corrosion Resistance: The combination of fiberglass reinforcement and resin matrix in FRP pultruded tubes provides exceptional resistance to corrosion. They are immune to rust, rot, and degradation caused by exposure to chemicals, moisture, UV radiation, and harsh environmental conditions. This makes them ideal for applications in corrosive environments, such as marine, chemical processing, or infrastructure exposed to aggressive elements.

Electrical Insulation: FRP pultruded tubes are electrically non-conductive, making them suitable for applications where electrical insulation is required. They do not conduct electricity, reducing the risk of electrical accidents or interference.

Dimensional Stability: FRP pultruded tubes exhibit excellent dimensional stability, meaning they maintain their shape and dimensions over time. They are not susceptible to warping, swelling, or shrinking due to changes in temperature or humidity, ensuring long-term performance and accuracy in various applications.

Design Flexibility: The pultrusion process allows for the production of FRP tubes with complex shapes, including round, square, rectangular, or custom profiles. This design flexibility enables the tubes to be tailored to specific application requirements, including load-bearing capabilities, structural support, or functional integration.

Easy Installation and Maintenance: FRP pultruded tubes are lightweight and easy to handle, transport, and install. They often require minimal maintenance, as they are resistant to corrosion, rot, and degradation. This reduces the overall lifecycle costs associated with maintenance and replacement.

FRP pultruded tubes find applications in various industries, such as construction, infrastructure, transportation, electrical, and industrial sectors. Common uses include structural supports, framework, handrails, ladder rungs, antennas, poles, and components in equipment and machinery where high strength, corrosion resistance, and electrical insulation properties are required.

What are some applications of air duct pipe?

Air duct pipes are used in HVAC (Heating, Ventilation, and Air Conditioning) systems to facilitate the distribution of conditioned air throughout buildings or enclosed spaces. These pipes play a crucial role in maintaining proper airflow, temperature control, and air quality. Here are some common applications of air duct pipes:

Residential HVAC Systems: Air duct pipes are extensively used in residential buildings for heating and cooling purposes. They connect the central heating and cooling units to various rooms, delivering conditioned air and ensuring comfortable indoor temperatures.

Commercial and Industrial HVAC Systems: Air duct pipes are essential components of HVAC systems in commercial buildings, such as offices, retail stores, hospitals, schools, and industrial facilities. They distribute conditioned air to different zones or areas, providing a comfortable and healthy indoor environment.

Ventilation Systems: Air duct pipes are also used in ventilation systems, which help remove stale air, odors, and contaminants from enclosed spaces. Ventilation ducts extract air from kitchens, bathrooms, laundries, or other areas prone to moisture, heat, or pollutants, and exhaust it to the outside.

Exhaust Systems: Air duct pipes are employed in exhaust systems to remove air or fumes generated by specific processes or equipment. Industries such as manufacturing, laboratories, workshops, or commercial kitchens utilize exhaust ducts to safely expel harmful gases, smoke, or by-products.

Fresh Air Intake: Air duct pipes can be dedicated to bringing fresh air from the outside into the HVAC system. This helps maintain proper ventilation and indoor air quality by introducing a controlled amount of fresh outdoor air to balance the recirculated air.

Return Air Systems: Air duct pipes are part of return air systems, where they collect and return air from various spaces back to the HVAC system for reconditioning. Return air ducts ensure the circulation of air, allowing the HVAC system to regulate temperature, humidity, and filtration effectively.

Energy Recovery Systems: Air duct pipes can be integrated into energy recovery ventilation systems. These systems use heat exchangers to recover energy from the outgoing air and transfer it to the incoming fresh air, reducing energy consumption and improving HVAC system efficiency.

Sound Attenuation: Air duct pipes can incorporate sound insulation materials or designs to reduce noise transmission within the HVAC system. This helps maintain a quiet and comfortable indoor environment by minimizing the transfer of noise generated by the equipment or airflow.

Overall, air duct pipes are fundamental components of HVAC and ventilation systems, enabling the efficient and controlled distribution of conditioned air, removal of stale air, and maintenance of indoor air quality. The specific application and design of the air duct pipes depend on the building type, HVAC system requirements, local codes, and environmental considerations.

FRP Accessories Technical Support and Service

At FRP Accessories, we are committed to providing our customers with superior technical support and service. We provide a comprehensive suite of resources and services to ensure the best possible experience for our customers.

Technical Support

We offer a variety of online and telephone technical support services to help our customers with their technical issues. Our knowledgeable staff is available to assist with product installation, technical troubleshooting, and product advice. We also provide detailed product documentation and user guides to ensure our customers can use our products quickly and effectively.

Warranty and Repair Services

We offer a comprehensive warranty and repair service for our products. Our service includes repairs for defective parts, as well as replacements and upgrades. We also provide warranty information and support for our customers.

Product Upgrades

We offer product upgrades for our customers to keep up with the latest technology. Our upgrades include firmware and software updates, as well as hardware upgrades. We also provide installation and technical support for our product upgrades.

Customer Care

At FRP Accessories, we are dedicated to providing our customers with the best possible experience. Our customer care team is available to answer any questions or concerns our customers may have. We strive to provide a positive and helpful customer experience for all of our customers.

Hubei Yuezhongxin New Composite Material Manufacturing Co., Ltd., founded in 2010, is providing customers with high-quality and affordable Fibreglass Reinforced Plastic (FRP) products, including FPR grille, pultruded pile, molded profiles, non-conductive ladder, square tube, and a wide variety of accessories.

Supply Ability

2, 000 Metre(s)/Week on average

Less amount if your product needs a new mould

Packing & Delivery

Packaging Details: Film Package on Pallet

Port: Shenzhen / Wuhan

Lead time: 3 - 8 days

By sea, By air or By express, you can have your own choice.

We try our best to pack and protect the goods according to

customer's requirement on the basis of international logistic

standard.

FAQ

Q1: Are you a trader or manufacturer?

A1: We are an OEM with our own manufacturing machines and

equipment, operated by around technicians and operations in 3

workshops located in Guangshui City, Hubei Province, China.

Q2: What’s your terms of payment?

A2: Usually, we accept T/T, irrevocable L/C at sight. For regular

order, we prefer 30% in advance and then the remaining 70% before

shipment from the factory.

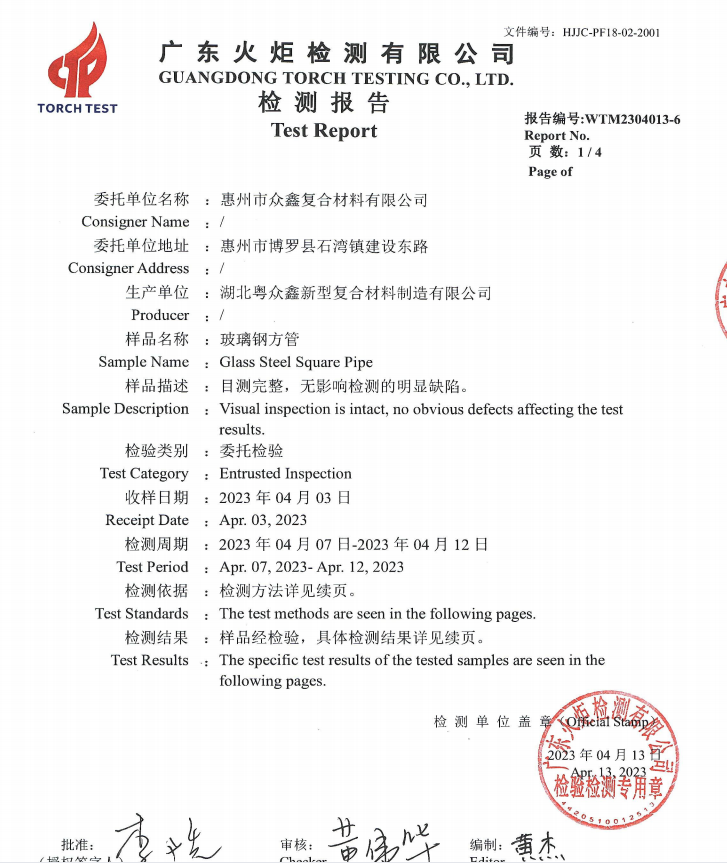

Q3: How do you control the quality?

A3: We have a quality department to inspect quality daily. We also

support third party test at every deal and the certificate of our

FRP products are exhibited in the company website.

Q4: What about lead or shipping time?

A4: The lead time depends on quantity you ordered, but generally we

complete the shipment within 8 days. However, lead time will be

longer if your demand is special.

Q5: How to pay sample and express charges?

A5: We provide samples for free and you only need to pay the

express charges. We have some cooperated express companies to help

if necessary.