Jinan MT Machinery & Equipment Co., Ltd. |

|

Product Description:

Core filling snacks food extruder production line from the raw materials, extrusion, core filling, press shapes, cutting, coating, flavouring can be finished one time, high automation.

Main Features:

1) Direct transmission between motor and gear box,reducing energy

consumption.

2) Feeding,main driving device, and rotary cutting device adopt

inverter to adjust the speed with more powerful drive, stable

running, and low consumption.

3) Screw is made of alloy steel with long life.Segmental assembled

screws are applied tomore kinds of materials and products

4) Automatic lubrication system can lower down power consumption

and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging mould and knives seat and bearing knife adjusting system

can adjust the kniver exactly and swiftly.

Model | Power Consumption | Actual Consumption | Output |

size |

MT65 processing line | 84KW | 59KW | 100-150 kg/h | 25000*1500*2000 mm |

MT70 processing line | 132KW | 92KW | 150-200 kg/h | 30000*1500*2000 mm |

MT70C processing line | 155KW | 105KW | 200-250 kg/h | 35000*1500*3000 mm |

Details Images of snack pellet production line:

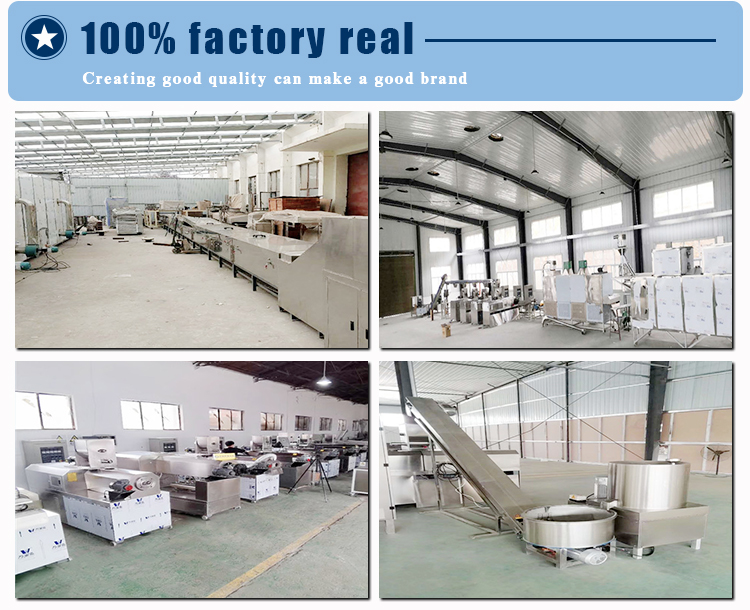

Company Profile of snack pellet production line:

Our company(MT Machinery Co., Ltd.'s )has good experience of the industry development. We have well-experienced managers,outstanding engineers as well as well-trained technical workers. By constant technical exchange with well-known firms of the same line in the world and also by introduction of advanced technique and experience into our company, we have established a strong technical guarantee system. Our company is a manufacturer of puffed extruder and food machinery. Our products are sold very well throughout China and are also introduced to Southeast Asia, East Europe, Africa and other regions.Our market share is increasing each year.

Packing & Delivery of snack pellet production line:

♥Wooden or metal case according to specific size of each equipment,

we twine thick plastic coating for each machine.

♥Tight the equipment in the truck without space to ensure no

rubbing during the transportation.

♥We can adjust according to the customer’s demand.

Certification of snack pellet production line:

We can provide the electronic edition certificates for Jinan MT Machinery extruded Double Screw Extruder Snacks Sclicone Making Pillow Core Filling Machine Snack Food Production Line if asked, or you can see the original documents in our factory. We can ensure the truth of our certificates.

Our services of snack pellet production line:

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea

installation and commissioning equipment;

4)Technician will work with your workers together and teach your

workers how to install machines,

how to operate machines, how to maintain machines during daily

working;

5)Our engineers will teach your workers how to clean the extruder,

how to change the screw,

how to change barrel etc, and provide technology support with you

forever;

6)Provide English Version of Installation / Operation / Service /

Maintenance Manual.