Jiangyin Golden Machinery Equipment Co , Ltd |

|  |

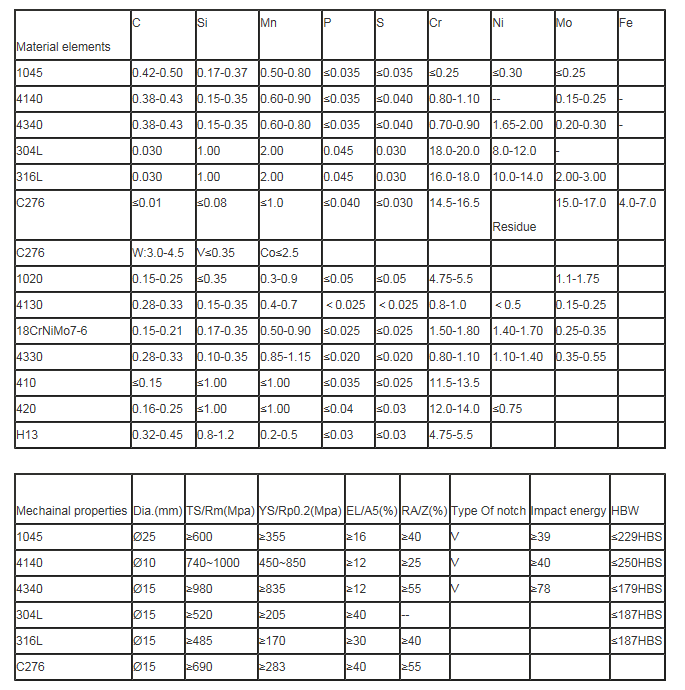

Cold Rolling Sae1045 C45 Aisi4140 SS416 SS316 ASTM

Polishing Bright Piston Rod

Company profiles

We are a company could offer you all kind of steel polished round

bar with bright surface and polishing surface.

The steel polished round bar is widely used for various

industries. For example: Metallurgy, mining, power station and so

on. The manufacturing equipment is 185MN or 100MN hydraulic press.

The main out diameter is from 30mm to 650mm.The surface could be

bright surface, chrome plated bright surface. The lengths are

produce according customer's require. We assure the quality of each

step.

The product can be provided as per your drawing or specified

requirements.

Smelting Process:EF+LF + VD+VC

The process as follow :Ingot →Heat → Forging → Heat treatment

(Normalizing+ tempering) → Inspection →Rough machining→UT

→2nd Heat treatment →Finishing machining →Inspection

Applications: The heavy forging: forged ring, shaft, roller,

flange, or gear is widely used for various industries For example:

Metallurgy, mining, power station and so on.

Specifications:

| Description | Cold drawn Sae1045 SS316 SS416 SS630 St52 steel bright piston rod |

| material | Alloy steel or stainless steel |

| Material standard | ASTM or GB/T3077-1999 |

| Specification | As per specified requirements |

| Weight | Max. 10 ton |

| Smelting Process: | EF+LF + VD+VC |

| Process | Ingot→heat → forging → Heat treatment (Normalizing+ tempering) →

Testing →Rough machining→UT →2nd Heat treatment →Finishing machining →Inspection |

| UT standard | EN10228, ASTM A388 or JB/T 5000.15-1998 |

Competitive Advantage:

The steel polished bar is manufactured from cold drawn or cold

milling. Advanced technical process from smelting steel to forging

and heat treat guarantees the product quality. Closed relationship

with several famous stated enterprises guarantee "in-time delivery"

and competitive price.

Excellent product quality and service, competitive price, "in-time"

delivery.

Our engineers are professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

1) Checking the raw material after they reach our factory-------

Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass

production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality

control(FQC)

5) Checking the goods after they are finished-----Outgoing quality

control(OQC)

Packing adn Delivery