Jiangyin Golden Machinery Equipment Co , Ltd |

|

Forging ISO9001 Heavy Duty Stamping Seamless Steel Wheel

Blank

Company profile

We are the manufacturer specialized in machining heavy duty forging

parts for nearly 18 years.Our products, such as drive shaft,

Forging Hollow Shaft, Shaft Sleeve, Eccentric shaft, Forging rod,

Large bolt, Heavy Duty Hydraulic Cylinder, are widely used in

coiled material, petroleum, metallurgy, mine, machinery and

transportation industry. etc.

Packaging & Delivery

| Packaging Details: | Export standard package or according to customer requirement |

| Delivery Detail: | 30~60days according to various quantity |

Product Flow

1.Inquiry with drawings in details.

2.Confirm steel material, chemical compositions, mechanical

properties, tolerance.

3.Confirm payment terms,order materials or check material in stock.

4.Check material chemical compositions, material weight,

dimensions.

5.Cut materials record weight, making mould for casting of

pr-hearting for forging.

6.Forging ratios, heat treatment ,dimension check.

7.Rough machining, UT test,heat treatment.

8.Semi-finish, quenching,

8.Fine machining, UT test, dimension inspection, mechanical

properties test.

9.Customer inspection, packing, delivery arrangement.

Steel ingot making

EAF+LF+VD/VAD or ESR

Manufacturing process

EAF + LF + VD+ Forging+ Normalizing & Tempering + Rough

machining + UT test + Quenching & Tempering + Precision

machining

Report

Chemical composition report, Physical properties report, Heat

treatment report, Dimensional inspection report, NDT report

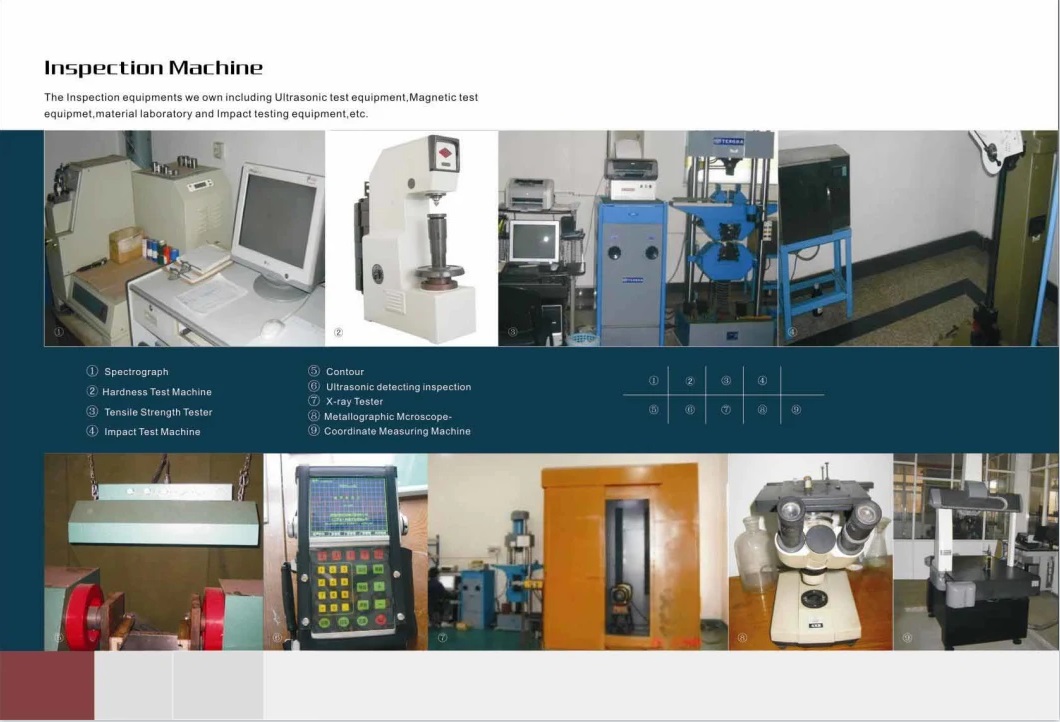

Nondestructive test (NDT)

UT ( ultrasonic testing ), MT ( magnetic particle testing ), PT (

penetrant testing)

Quality certification : ISO 9001: 2008, IQNET