Jiangyin Golden Machinery Equipment Co , Ltd |

|

Open Die Forging Steel 60T, A105 AISI4140 A36 St52 S355 Flat Bar

Heat treatment:

Normalized / Annealed / Quenched / tempered

Surface Treatment:

painting,plating,polishing,black oxide,transparent anti-rust oil

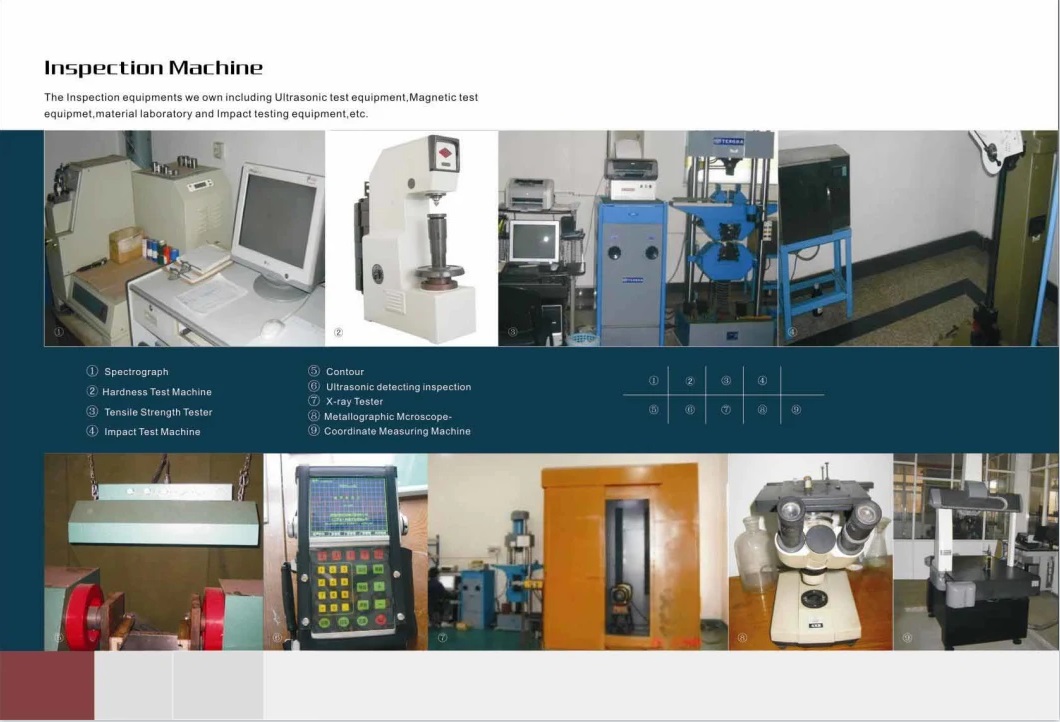

Quality control:

UT,MT,RT,PT,chemical composition test,mechanical property test,etc.

Inspection:

1, Raw material certificate(material chemical composition) 2, Heat

treatment sheet report

3, Dimension inspection report 4, UT test report

Delivery condition:

Hot forged +Rough machined (black surface after Q /T)+ Turned

Competitive Advantage:

Quality control and management to the whole produce process,

including ingot smelting, forging, heat treatment, machining and

strictly final inspection prior to delivery.

Excellent product quality and service, competitive price, "in-time"

delivery.

Specifications

1) Product Name: Forged crankshaft, crankshaft Forging

2) Material: 4130, 4140, 4317, 4142, 4340, UNS440, 34CrNi3Mo,

25Cr2Ni4MoV, 18CrNiMo5, 30CrMo, 9Cr2Mo, 9Cr2W, 9Cr3Mo, 60CrMoV etc.

3) Max weight: 60ton.

4) MOQ: 10ton.

5) FOB Port: Shanghai Port, China.

6) Delivery Time: 60ton in 30 days.

7) Delivery Condition: Rough Machined, Heat Treated, Fine Machined

+ EN10204: 3.1B

8) Payment: 30% T/T in advance, Balanced C. A. D.; Or 100% L/C.

Mill Frequently Used Steel Materials:

1) Wind Power Shaft: 42CrMo4V, 34CrNiMo6; Wind Power Flange:

S355NL, C22, 16Mn, 20Mn, 42CrMo, F304.

2) Forged Pipe Fittings:SA182 Gr. F1, Gr. F5, Gr. F11 CL2, Gr. F12

CL2, Gr. F22 CL3, SA350 Gr. LF1, Gr. LF2,Gr. LF3.

3) Pressure Vessel Forgings: SA105, SA350 LF2, 16Mn, 20MnMo,

15MnMo, 12Cr2Mo1, 14Cr1Mo, F304, F316, 17-4PH.

4) Shaft Related Forgings: 25CrMo4, 42CrMo4, 40CrNiMo, 34CrNi3Mo,

25Cr2Ni4MoV, 18CrNiMo5, 30CrMo, 4130, 4140.

5) Gear Related Forgings: 35CrMo, 34CrMo4, 4137, 42CrMo, 4140,

SCM440, 20CrMnMo, 40CrNiMo, 20CrNi2Mo,34CrNi3Mo.

6) Copper Forgings: C10100, C10200, C10300, C10700, C12000, C12200.

We are professional in die forgings and castings, ring, shaft,

gear, flange, cylinder and other products.

Our goal is not just providing products, but also providing a

complete solution including product design, tooling, fabrication

and service for our customers to achieve their upper most

satisfaction.

We stick to the principle of "quality first, service first,

continuous improvement and innovation to meet the customers" for

the management and "zero defect, zero complaints" as the quality...

| Item | Process | Facility |

Inspection items

| Standard |

|---|---|---|---|---|

01 | Steel material inspection | Chemical composition (EF+LF+VD) | Material standard | |

| surface | Ingot inspection specification | |||

| Ingot type and weight | Material standard | |||

| 02 | Material store | Division put | warehouse management | |

| 1 | Heat | Heat furnace | Temperature/Time | Heating process specification Forging production procedure |

| 2 ↓ | Forging | Press | Reduction ratio,forging temperature,deformation, Surface and dimensions | Forging process card Forging procedure |

| 3 ↓ | Heat treatment | heat treatment furnace | heat treatment charts | 1st heat-treatment card Forging procedure |

| 4 ↓ | Rough inspection | Dimensions, apperance, Mark | Inspection specification Forging procedure | |

| 5 ↓ | Rough UT | UT equipment | Single defect, concentrated Defects bottom wave attenuation | UT standard or customer's technical requirements |

| 6 ↓ | Saw cutting | Saw machine | Dimension | IQC and forging |

| 7 ↓ | rough turning | turning-lathe | Dimension,appearance | Rough machining drawing |

| 8 ↓ | UT | UT equipment | Single defect, concentrated defects bottom wave attenuation | UT standard or customer's technical requirements |

| 9 ↓ | Q+T heat treatment | heat treatment furnace | heat treatment charts | Heating process specification |

| 10 ↓ | Sampling or machining | machining tool | rough machining drawing sampling drawing | sample machining drawing |

| 11 ↓ | mechanical property test | tensile testing machine/ impact testing machine | ambient temperature,humidity, Test temp.Sample dimension, test method | Standard technical specification |

| 12 ↓ | finish machining | machining tool | Dimension,appearance | finish machining drawing |

| 13 ↓ | UT | UT equipment | Single defect, concentrated Defects bottom wave attenuation | UT standard or customer's technical requirements |

| 14 ↓ | MT | MT equipment | Magnetic particle indication | Test standard or Technical requirements |

| 15 ↓ | Mark | Steel seal | marking content | Product standard Technical requirements Forging process |

| 16 ↓ | Final inspection | Appearance, dimension, mark acceptance inspection | Product inspection specification Product standard P.O. | |

| 17 | Protection/ package | Blasting Blasting equipment | appearance coating thickness | Product standard Technical requirements |