ZIZI ENGINEERING CO.,LTD |

|

Zizi Engineering is ISO certificated manufacturer of forged pipe fittings, we supply socket weld elbow, tee, coupling, cap and union in stainless steel, carbon and alloy steel. The dimensions can be according to ASME B16.11, BS 3799 or customized. As a high quality pipe fittings manufacturer, we offer you product quality certificate no matter the quantity.

Chemical Composition

| C | Mn | P | S | Si | Cr | Ni |

| 0.08 | 2 | 0.045 | 0.03 | 1 | 18-20 | 8-11 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

| 515 (Mpa) | 205 (Mpa) | 30 (%) |

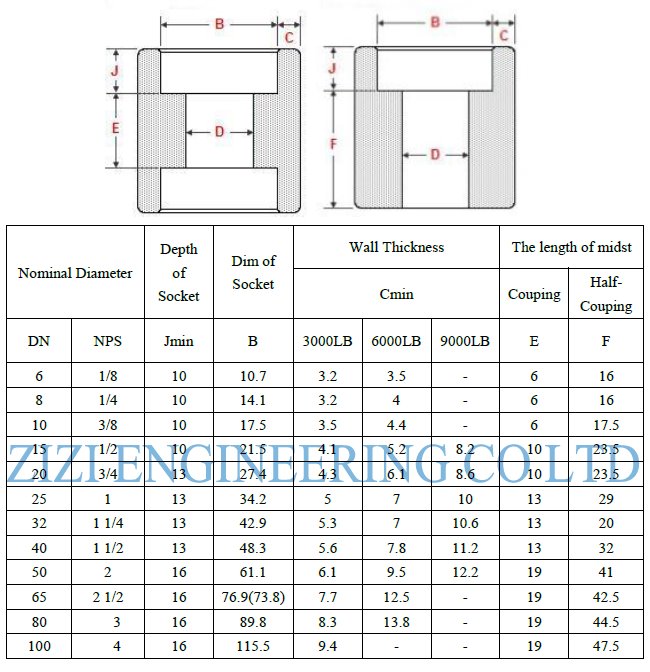

| Size | 1/8", 1/4", 3/8", 1/2", 1/4", 1", 1 1/4", 1 1/2", 2", 2 1/2", 3", 4" |

| Pressure Rating | 3000#, 6000#, 9000# |

| Standard | ASME B16.11, BS3799, JIS B2316, HG/T21634, SH3410, GB/T14383 |

| Surface | Anti-rust oil or Galvanized |

| Type | 45° Elbow, 90° Elbow, Equal Tee, Reducing Tee, Full Coupling, Half Coupling, Pipe Cap, Pipe Union |

Carbon Steel Half Coupling

ASTM A105, A350 LF2, LF3, A694 F52, F60, F65, F70

Alloy Steel Socket Weld Coupling

ASTM A182 F1, F5, F9, F11, F12, F22, F91

Stainless Steel Reducing Coupling

ASTM A182 F304/304L/304H, F316/316L, F310, F317, F321,F347

Duplex Stainless Steel Coupling

ASTM A182 F51, F53, F55, S31803, S32205, S32550, S32750, S32760

Marking and Packing

Inspection

● 6000# Socket weld coupling is applied for 4” under pipe system

● High leakage integrity

● Great structural strength

● Lower fatigue resistance than butt weld fittings

● Can be used to flammable, toxic, high pressure and high temperature pipeline.

● Designed to provide good flow characteristics

● No need for alignment.