ZIZI ENGINEERING CO.,LTD |

|

ASME B16.11 Socket Weld Tee 2 x 1 1/4 " A105N 6000 # Carbon Steel Pipe Fittings

ASME B16.11 Socket Weld Tee

Best quality ASME B16.11 Socket Weld Tee 2 x 1 1/4 " A105N 6000 # Carbon Steel Pipe Fittings for you. We supply socket weld fittings, threaded fittings and butt weld fittings in different materials.

We manufactured, tested and certified the forged steel fittings in accordance wtih ASME 3A-105N & ASTM A105N Normalized.

Our socket welding pipe fittings are designed and developed to meet diverse working conditions and special project requirements of our customers.

| Size | 1/8" to 4" / DN6 to DN100 |

| Pressure Rating | Class 3000, 6000, 9000 |

| Standard | ASME B16.11 and BS3799 |

| Surface | Anti-rust Oil |

| Type | Equal Tee, Reducing Tee |

| Stainless Steel | ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321 |

| Caron Steel | ASTM A105, A350 LF2, LF3, A694 F52, F60, F65, F70 |

| Alloy Steel | ASTM A182 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel | ASTM A182 F51, F53, F55, S 31803, S 32205, S 32550, S 32750, S 32760 |

| C | Mn | P | S | Si | Ni | Cr | Mo |

| 0.35 | 0.6-1.05 | 0.035 | 0.04 | 0.1-0.35 | 0.4 | 0.3 | 0.12 |

| Tensile Strength | Yield Strength | Elongation | HB |

| 485 (Mpa) | 250 (Mpa) | 22 (%) | 187 |

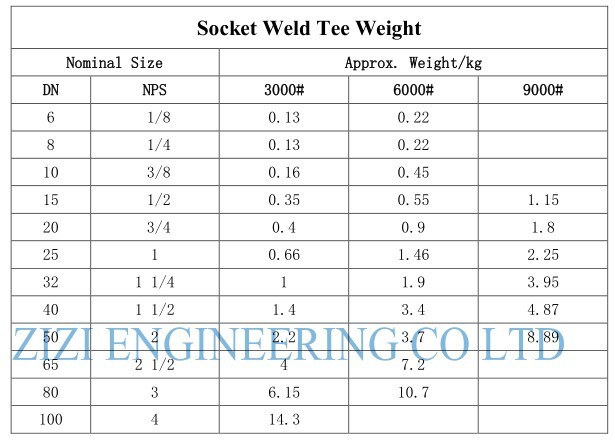

We offer you the weight of socket weld tee equal type because of the limited space. The weight of reducing tee is based on the equal tee type.