ZIZI ENGINEERING CO.,LTD |

|

Socket Weld Elbow 1 1/2 " 3000 LB A182 F5 ASME B16.11 Alloy Steel Pipe Fittings

Alloy Steel Pipe Fittings

We have large socket weld fittings in inventory and export Socket Weld Elbow 1 1/2 " 3000 LB A182 F5 ASME B16.11 Alloy Steeel Pipe Fittings with high quality. We deliver all forged steel fittings in short time and good package. The shipment can be air or container. It depends on the quantity and customer.

| Size | 1/8" to 4" / DN6 to DN100 |

| Pressure Rating | Class 3000, 6000, 9000 |

| Standard | ASME B16.11 and BS3799 |

| Surface | Anti-rust Oil or Galvanized |

| Product | 90 Degree Socket Weld Elbow,45 Degree Elbow, Equal Tee, Reducing Tee, Socket Weld Coupling, Cap and Union |

| Stainless Steel | ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321 |

| Caron Steel | ASTM A105, A350 LF2, LF3, A694 F52, F60, F65, F70 |

| Alloy Steel | ASTM A182 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel | ASTM A182 F51, F53, F55, S 31803, S 32205, S 32550, S 32750, S 32760 |

ASTM A182 F5 Chemical Composition

| C | Mn | P | S | Si | Ni | Cr | Mo |

| 0.15 | 0.3-0.6 | 0.03 | 0.03 | 0.5 | 0.5 | 4-6 | 0.44-0.65 |

ASTM A182 F5 Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

| 620 (Mpa) | 450 (Mpa) | 22 (%) |

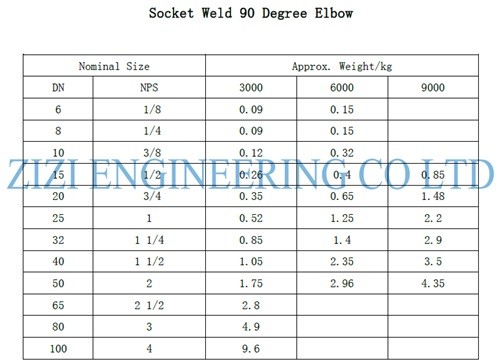

Here is the weights of 90 degree socket weld elbow, the dimensions we give is in accordance with ASME B16.11.