ZIZI ENGINEERING CO.,LTD |

|

Socket Weld Reducing Tee ASTM A182 SS 304 1 x 1 / 2 Class 6000 ASME B16.11

SS 304 Reducing Tee

Best price for high quality ASTM A182 SS 304 Scoket Weld Reducing Tee in Class 6000, their quality is guaranteed by ISO certified company. We export 1" x 1/2" Forged Fittings to Southeast Asia, Africa, Australia, South America and so on.

SS 304 Forged Fittings are high strength, corrosion resistant fittings so that they can withstand high pressure and temperature. You can used them in food, marine, chemical industries and any corrosive environments.

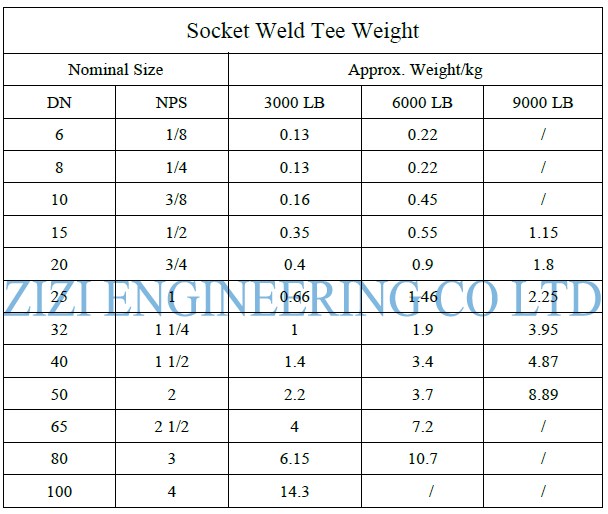

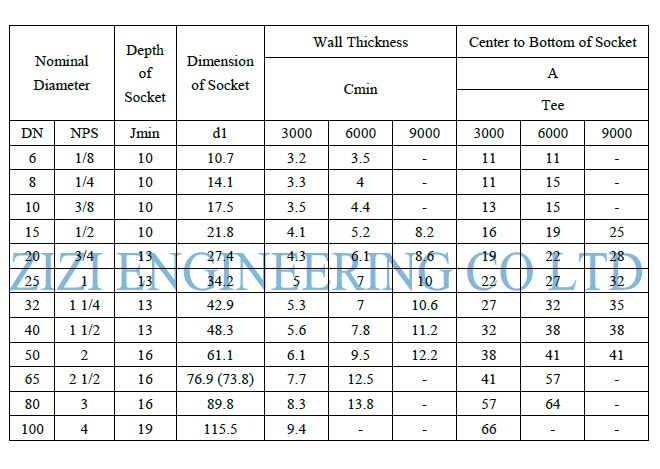

| Size | NPS1/8" to 4" / DN6 to DN100 |

| Pressure Rating | Class 3000, 6000, 9000 |

| Standard | ASME, ANSI, DIN, GB/T, JIS |

| Surface | Anti-rust Oil |

| Type | Equal Tee, Reducing Tee |

| Stainless Steel | ASTM A182 F304/304L/304H, F316/316L, F310, F317, F321 |

| Caron Steel | ASTM A105, A350 LF2, LF3, A694 F52, F60, F65, F70 |

| Alloy Steel | ASTM A182 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel | ASTM A182 F51, F53, F55, S 31803, S 32205, S 32550, S 32750, S 32760 |

| C | Mn | P | S | Si | Ni | Cr | Mo |

| 0.08 | 2 | 0.045 | 0.03 | 1 | 8-11 | 8-20 | / |

| Tensile Strength | Yield Strength | Elongation |

| 515 (Mpa) | 205 (Mpa) | 30 (%) |