GUANGDONG SHANAN TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

High Sensitivity Food Grade Metal Detector For Frozen Food , HACCP / ISO9001

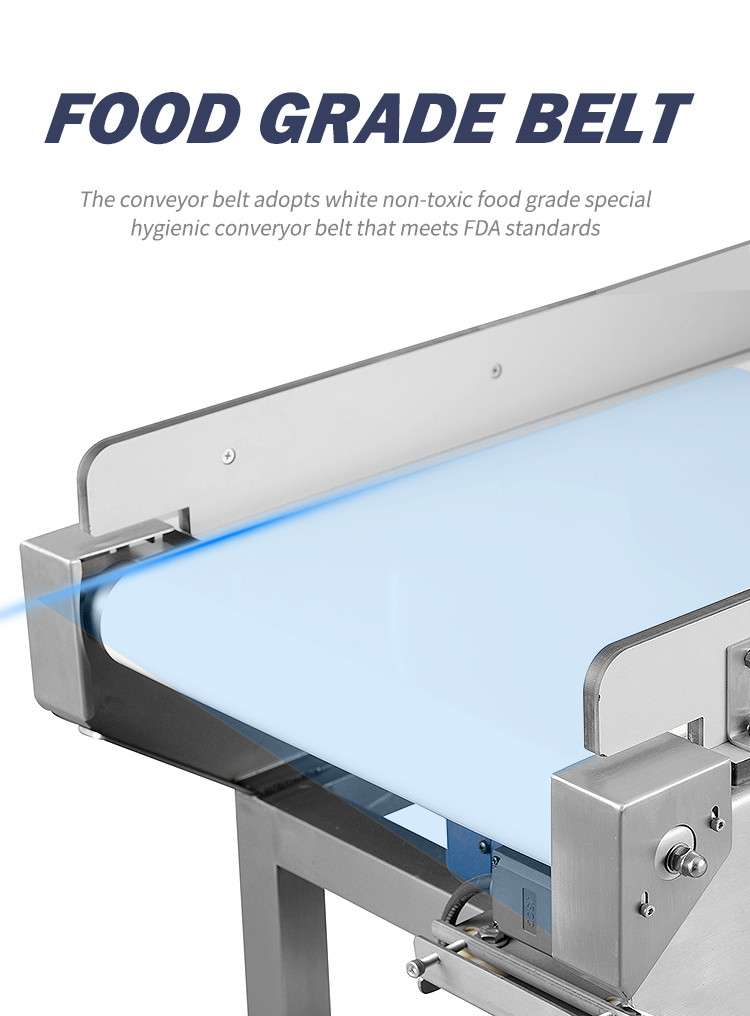

Conveyor Systems are custom manufactured from heavy duty stainless steel to fit the unique metal detector and application. The robust conveyors maintain optimal performance under harsh conditions and heavy products, and can be built to withstand washdown environments. Reject systems such as air blasts, kickers, simple retracts and belt stop alarms are available and modular in design depending on the type of product being inspected. Hygienic conveyor belts are tailored to each application, including various belt sizes, belt configurations, and sensors that maximize detector accuracy and efficiency.

Renowned for their superior accuracy and reliability, Conveyor Systems act as essential Critical Control Points in HACCP systems, effectively identifying and rejecting potential contamination.

Product Benefits

Features:

KEY FEATURES

Sensitivity Requirements

The equipment must achieve the following:

Sensitivity must be stable and require infrequent adjustment

Not reject good product or provide false positive results

Be capable of detecting metal in various orientations

relative to the detection head

It is important to work with your equipment supplier in determining

and establishing these conditions. Sensitivity levels must be

realistic and attainable and your supplier will be best placed to

provide guidance. In some cases customer technical standards will

also provide suggested sensitivity

levels for their products. The following are sample sensitivities

(mm) based on pack size

Details Tunnel size | 40*12cm | 40*15cm | 40*20cm | 50*15cm | 50*20cm | 50*25cm | 50*30cm |

| Sensitivity Fe(mm) | 0.8 | 1.0 | 1.2 | 1.0 | 1.2 | 1.5 | 2.0 |

| Sensitivity SUS(mm) | 1.5 | 2.0 | 2.5 | 2.0 | 2.5 | 3.0 | 3.5 |

| Detection height | 120 | 150 | 200 | 150 | 200 | 250 | 300 |

| Detection width | 400 | 500 | |||||

| Belt speed |

10-35 meters per minute adjustable | ||||||

| Alarm method | Light and sound and optional reject | ||||||

What are the considerations for purchasing a metal detector?

Decide what types of metal you need to detect. There are two main

categories of metal: ferrous and non-ferrous. Ferrous metals are

derived from iron or contain iron. Non-ferrous metals are all

others. Take a careful inventory of the types of metal in your

operation that could possibly end up in your products.

What sizes of metal contaminants do you need to screen for? You

need to be practical and realistic with this question because if

you specify too much sensitivity, you will get too many false

alarms and vice versa.

Know the operating environment and the product characteristics –

The operating environment includes the temperature and whether

water, dust, or chemicals could come in contact with your metal

detector, as well as possible electrical fields. Additionally, is

the product fresh or frozen, packaged or exposed, scanned

individually or in a case? All of these factors will go into the

design of a metal detector that will fit your needs the best.

Reject System considerations – Most commonly, a pusher or an air

blast is used to divert products where metal has been detected.

However, you could save space by having the conveyor belt stopped

and a warning light activated. Additionally, an optional Lockable

Collecting Container prevents unauthorized employees from gaining

access to rejected product.

Optional reject 1 :Push rod

Optional 2 flap drop

Optional 3 Air blast