Jinan Darin Machinery Co., Ltd. |

|

Hot Sales Pet Treats Injection Molding Machine with PLC Touch Screen

Introdution

An Injection molding machine, or (Injection moulding machine ),

also known as an injection press, is a machine for manufacturing

pet treats products by the injection molding process. It consists

of two main parts, an injection unit and a clamping unit. is

special machinery for producing pet snacks.

With such machine, various shapes can be made, such as hedgehog,

crocodile, dog, bone, pork ears, barrel, etc.The shapes are very

lovely and it is a ideal encouragement to dogs and cats while they

learn a new action or do well in some exercises and games. Also, we can provide different recipes to meet various market

demands.

Operation

Injection molding machine molds can be fastened in either a

horizontal or vertical position. The majority of machines are

horizontally oriented, but vertical machines are used in some niche

applications such as insert molding, allowing the machine to take

advantage of gravity. Some vertical machines also do not require

the mold to be fastened. There are many ways to fasten the tools to

the platens, the most common being manual clamps (both halves are

bolted to the platens); however, hydraulic clamps (chocks are used

to hold the tool in place) and magnetic clamps are also used. The

magnetic and hydraulic clamps are used where fast tool changes are

required.

The person designing the mold chooses whether the mold uses a cold runner system or a hot runner system to carry the plastic and fillers from the injection unit to the cavities. A cold runner is a simple channel carved into the mold. The plastic that fills the cold runner cools as the part cools and is then ejected with the part as a sprue. A hot runner system is more complicated, often using cartridge heaters to keep the plastic in the runners hot as the part cools. After the part is ejected, the plastic remaining in a hot runner is injected into the next part.

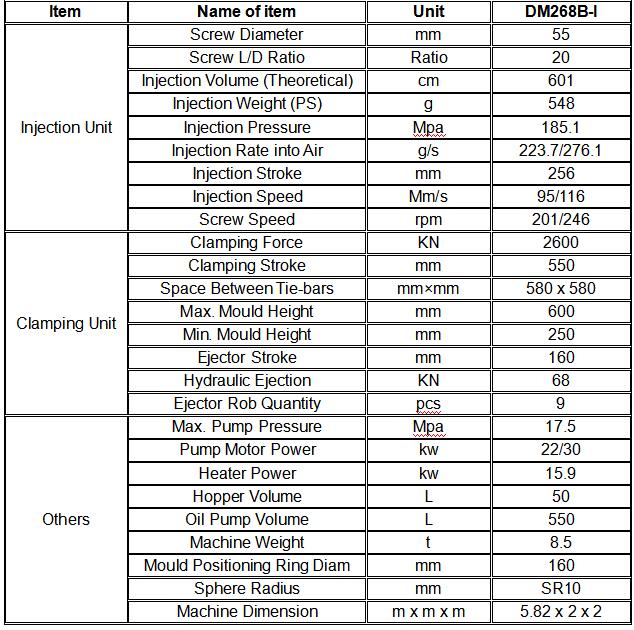

Technical Parameter

1. Screw rotating speed read-out.

2. Security code function to avoid missing data or careless

changing.

3. Super low pressure clamping ensures security of user, and

maintains lifespan of machine efficiently.

4. The response time of the drive system is very fast. It requires

only 0.005s to reach the maximum power output, greatly shorten the

cycle time.

5. The precision of processing tolerances to produce the plastic

parts will be greatly improved. The optimized rate of repeated

qualified parts is around 40-130%.

6. Equipped with a rotary encoder and pressure sensor, the pressure

flow state of the energy saving the machine will be transmitted to

the controller, the command of which will be sent out to the

efficient synchronous servo motor to change the rotation and the

torque accordingly.

FAQ

1. Could we visit your factory to check the machine carefully and closely?

You’re more than welcome to visit Darin, will provide machine test running, face to face discussion and turnkey project design solution.

2. Could you afford technician team to guide our installation and commissioning?

Oversea commissioning service provided, our technician will help to install the machine, and teach local workers about operation and maintenance. Buyer should pay for the technician's round flight ticket, accommodation and salary.

3. How long is your machine's guarantee time?

One year since the machine arrive your factory.

4. If some parts break after warranty, what should we do?

Darin supply full-life after sales service, whenever new parts needed, we will help to supply new ones at reasonable price & in shortest time.

5. If we show our workshop size, can you design layout for the whole line?

Auto CAD layout will be provided as client’s workshop size.

6. What is the material of the machine?

Stainless steel, especially parts contacting with materials, conforming to food grade.

Commissioning Service

1. We make accurate factory layout design according to customer’s

factory size; if the customer needed, we could make workshop design

with electricity power, water supply, gas power, material storage,

final storages, worker’s restroom, etc.

2. After delivering machines to client’s factory, we start to apply for the Visa to client’s country immediately; normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. While the machines arrives your factory, our engineers are ready to start for the commissioning service.

3. 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4. Our engineers have responsibility to train and teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line.

5. It normally costs 10 days for the commissioning

service, and we supply 1 year guarantee from the date of completion

of commissioning service.

6. The engineer’s round-trip flight tickets, accommodation and daily salary USD 60 are on client’s account.

Parameters:

Sample Picture

Pet Treats Molding Machinery for producing pet snacks and pet

chewing toys.