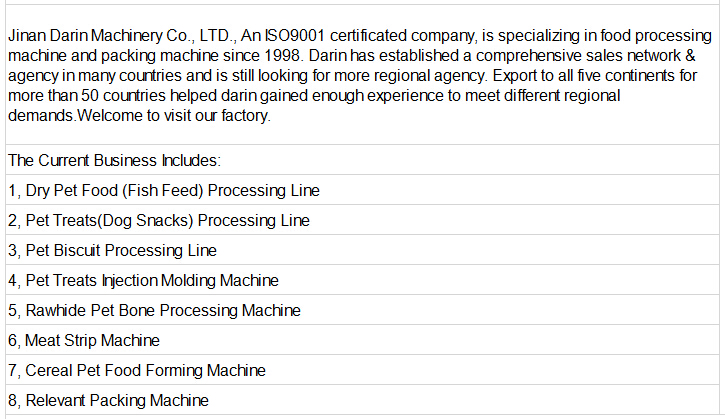

Jinan Darin Machinery Co., Ltd. |

|

Teeth Clean dog food manufacturing equipment / Molding Machine

Product Specification

Injection Dog Snack Moulding Machine is special machinery for producing pet snacks.

With such machine, various shapes can be made, such as hedgehog, crocodile, dog, bone, pork ears, barrel, etc.

The shapes are very lovely and it is a ideal encouragement to dogs and cats while they learn a new action or do well in some exercises and games.

Also, we can provide different recipes to meet various market demands.

Sample Picture

| Model | DM-268 |

| Screw diameter | 60mm |

| Screw L/D Ratio | 18.8 |

| Short volume | 707mm |

| Short Weight | 636g/22.4oz |

| Injection pressure | 142Mpa |

| Injection rate | 239g/s |

| Plasticizing capacity | 49g/s |

| Screw speed | 180rpm |

Technical Parameter

1. It comes with user-friendly microprocessor controller with these

following features;

2. Dust, oil proof and colorful touch switch control panel.

3. El display of pressure, speed, time and distance for each

motion.

4. Equipped with 4 stages injection, 3 stages holding pressure and

3 stages back pressure.

5. PID barrel temperature control: temperature abnormal &

electrical wire disconnection alarm.

6. SSR-solid state temperature controller.

7. Screw cold start protection.

8. Abnormal shot detection.

9. Output quantity and packaging quantity preset.

10. Clamping, injection and ejection (option), and carriage action

(option) by linear potentiometer.

Factory & Office

Commissioning Service

1. We make accurate factory layout design according to customer’s

factory size; if the customer needed, we could make workshop design

with electricity power, water supply, gas power, material storage,

final storages, worker’s restroom, etc.

2. After delivering machines to client’s factory, we start to apply

for the Visa to client’s country immediately; normally the vessel

needs 20-60 days to the required port, so we have enough time to

get the Visa. While the machines arrives your factory, our

engineers are ready to start for the commissioning service.

3. 1-2 of our engineers will go to your factory to install and

adjust the processing line to realize normal production at shortest

time.

4. Our engineers have responsibility to train and teach the workers

how to operate, clean, maintain and repair all the machines, until

the workers could well operate the processing line.

5. It normally costs 10 days for the commissioning

service, and we supply 1 year guarantee from the date of completion

of commissioning service.

6. The engineer’s round-trip flight tickets, accommodation and

daily salary USD 60 are on client’s account.