Ji nan keysong machinery co.LTD |

|

Low Noise Heat Pump Dryer Stable Full Automatic For Fish Drying

How does a heat pump work?

Heat pump is a high efficiency water heater. Its working principle is reverse Carnot cycle, Reverse Carnot cycle is refrigerant cycle, it consists of 4 important components. 1. evaporator. 2. compressor, 3. condenser, 4. expansion valve.

Heat pump dryer is use of reverse Carnot principle .With free air to absorb heat and transfer it to the

drying chamber, drying room temperature to achieve improved, with the appropriate humidity and

dehumidification equipment to achieve dry materials. heat pump dryer Compressor - heat exchangers

Chokes heat sink

(outside the machine) - Compressor and other devices constitute a refrigerant cycle system.

Under the action of the compressor in the refrigerant circulating in the system flow, it is done in the gaseous booster compressor heating process (temperature up to 100 ℃), releasing it into the machine

dry in room temperature air heated by the heat, while they have been and converted to liquid cooling

flowwhen it runs out machines, liquid absorbs heat quickly evaporates once again transformed into a

gaseous state, while the temperature dropped to minus 20 ℃ -30 ℃, then the air around the heat sink

willcontinuously transferring heat to the refrigerant. Refrigerant continuous cycle to achieve the heat in

the air transport to the drying room heating room air temperature to achieve the purpose of dry material.

Technical parameters

Model | KS03RD | KS06RD | KS10RD | |

Power supply | V/PH/HZ | 380/3/50 or 220/1PH/50 | 380/3/50 | 380/3/50 |

Power input | KW | 2.8 | 5.8 | 10.8 |

Running current | A | 8/17 | 12.6 | 22.5 |

Auxiliary electric heater(option) | KW | 9 | 9 | 9 |

Heating capacity | KW | 12 | 26 | 35 |

Cooling capacity | KW | 7.5 | 20 | 25 |

Dehumidification amount | L/H | 8 | 20 | 40 |

Max. hot air Temperature | ℃ | 75 | 75 | 75 |

Working ambient temperature | ℃ | -10~45 | -10~45 | -10~45 |

Refrigerant | Kg | Mixture type/2.5 | Mixture type/4.3 | Mixture type/8.0 |

Compressor | Type | Scroll | Scroll | Scroll |

Brand | Copeland/Danfoss | Copeland/Danfoss | Copeland/Danfoss | |

Quantity | 1 | 1 | 2 | |

Noise | dB(A) | 60 | 65 | 70 |

Fan motor for drying | Power input/unit | 250W/unit | 250W/unit | 250W/unit |

Wind volume | m3/H | m3/H | 2500m3/H/unit | |

Recommend qty | 8 | 8 | 16units | |

Heat regenerator size | mm | 500*350*350 | 500*500*580 | 550*600*680 |

Fan motor for heat regenerator | Power input | 200W | 370W | 550W |

Wind volume | 2000m3/H | 2000m3/H | 3500m3/H | |

Size(mm) | 450*330*380 | 470*320*470 | 580*320*580 | |

Wind valve | Power input | 6W | 6W | 6W |

OPEN | Exchange fresh air | Exchange fresh air | Exchange fresh air | |

CLOSE | Drying | Drying | Drying | |

Size(mm) | 480*320*120 | 630*560*120 | 720*640*125 | |

Fan motor for evaporator | Power input | 250W/unit | 780W/unit | 780W/unit |

Wind volume | 4600m3/H | 10500m3/H | 2*10500m3/H | |

Rotate speed | 1350RPM | 1350R/Min | 1350R/Min | |

Hot air outlet | mm | 600*1100 | 650*1100 | 860*1485 |

Hot air return inlet | mm | 690*1100 | 750*1100 | 1050*1450 |

Dimension(L*W*H) | mm | 1650*960*1280 | 1720*1160*1280 | 2100*1460*1590 |

Net weight | Kg | 210 | 385 | 480 |

Gross weight | Kg | 240 | 420 | 540 |

Application :

Dry vegetables like Radish, lettuce, pumpkin, carrots, spinach, cassava etc

Dry fruits like Apple, lemon, mango slices, apricot, longan, etc

Dry meat: Sausage, beef, duck, ham ect

Others it can dry noodle/ wooden /stick incense/herbs /flowers ect.

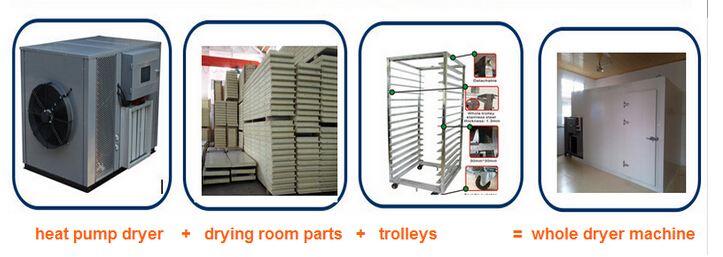

Advantages

1. Energy saving & Environmental protection

Adopt close dehumidify + circulating drying type, saving operating cost;

Without waste gas and waste heat pollution, low noise

2. Running Stable, operating easily

PLC + Touch Screen, running stable, operating easily;

Adopt PLC control, can setting different drying curve,

Suitable for drying different materials.

3. Second waste heat recovery technology (patent)

Adopt air to air heat exchanger dehumidify and recovery waste heat at the same time, saving energy more than 40%.

4. Exact control temperature and humidity

According to different material setting different drying curve, the heat pump dryer can control the drying chamber temperature between 20-80℃

5. Recovery volatilized component

Some kinds of material contain volatilized component, in drying processing, hot and wet air will become condenser water then drain, collect the condenser water so that collect volatilized component.

6. Safe and reliable operation, automatic intelligent control, 24-hour continuous drying.

Stable operation without being influenced by weather

7.Wide application, can be used in agricultural products, seafood, fruits and vegetables, fish, meat, nut, herb, wood drying systems.

Our service

Technical service

1, We calculate the capacity and recommend the best models.

2, We supply you the professional refrigeration technical support and electronic technical support

for your installation, debugging and operation.

3, We supply the spare parts and technical support in & after the warranty time.

4, We supply the training course to your workers at our factory if you need.

After-sales service

1, Technical support for your installation, operation and maintenance.

2, One year’s warranty, and you can pay for extended warranty.

3, Spare parts and technical support at most economic prices after the warranty.