Ji nan keysong machinery co.LTD |

|

Food Grade Corn Flakes Machienry , Breakfast Cereal Snack Food Extruder

Quick Details

Condition: | New | Place of Origin: | Shandong, China (Mainland) | Brand Name: | Keysong |

Model Number: | KS70 | Application: | corn flakes/breakfast cereals | Voltage: | 380/415/440V, etc |

Power(W): | as per final production line | Weight: | as per final production line | Dimension(L*W*H): | as per final production line |

Certification: | ISO9001/CE/SGS | Warranty: | 1 year | After-sales Service Provided: | Engineers available to service machinery overseas |

Name: | breakfast cereal/corn flakes making machine | Output: | 180-240kg/hr | Screws quantity: | 2 |

Main body material: | Stainless steel | Screws material: | Hard-wearing alloy steel |

|

|

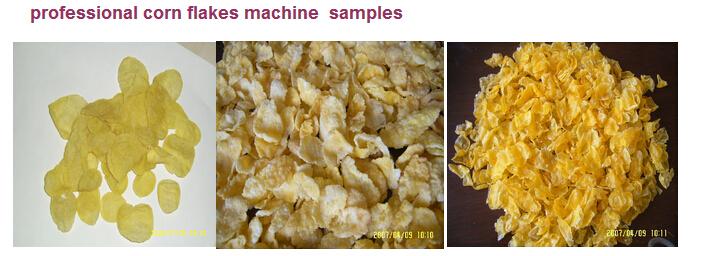

corn flakes extruding machine description

Corn flakes is one kind of nutrition convenient food which is produced by the corn flakes extruding machine using grist as basic material, with different shapes, The corn flakes outstanding characteristic is that it contains abundant compound carbohydrates and dietary fibre,strenghthens lots of microelements,such as vitamin and mineral, It can also be drunk directly after mixed into coffee, milk, yoghourt or functional drink.

corn flakes extruding machine Flow chart

Mixing system---Extrusion system----Cooling system—Flaking system--Drying system—Toasted system---Sugar Spraying system ---Drying system---- Packing system

1. Mixer : Mix the raw material equally

2. Elevator : take the raw material to the extruder

3. Twin screw extruder : mix , cook and extrude the raw material with suitable temp and pressure , first to produce cristal snack balls from the extruder

4. Vibrator : spread the pellet balls to avoid them sticking together

5. Air coveyor : blow the pellet balls to the flaker

6. Tablet machine: Press the snack balls into flakes with adjustable thickness

7. Air conveyor : Blow the corn flakes to the oven

8. Oven : dry the corn flakes to take away most of the moisture content

9. Elevator : take the corn flakes to the next machine

10. Hot air heater : puff the corn flakes to be expanded and crispy

11. Sugar sprayer : spray syrup onto the surface of the corn flakes to make sweet flavor

12. Vibrator : spread the coated corn flakes to avoid sticking together

13. Oven (extended ) : Bake the coated corn flakes to make them crispy again after syrup coating .

14. Cooling conveyor : cool down and convey the corn flakes

Raw materials of the corn flakes extruding machine

corn flakes extruding machine adopts corn flour as raw materials.

corn flakes extruding machine Capacity/Output

100-130kg/h, 200-240kg/h, 300-400kg/h

Voltage in China

Three phases: 380V/50Hz, we can make it according to customers’Local voltage according to different countries

Machines Materials of corn flakes extruding machine

All the machines are made by stainless steel.

The biggest advantage of the corn flakes extruding machine

the screw can self-clean automatically

Technical Parameters of corn flakes extruding machine

MODEL | INSTALLED POWER | REAL POWER | OUTPUT(KG/H) | DIMENSION(MM) |

KS65 | 45kw | 22kw | 120-150kg/h | 2600*900*1900 |

KS70 | 54kw | 45kw | 200-250kg/h | 2600*900*1900 |

KS85 | 94kw | 75kw | 350-500kg/h | 3900*900*1900 |

Who we are

Jinan KEYSONG Food Machinery Co., LTD is professional in producing food machines for more than 6 years. We concentrate many professional team, excellent engineers and talents in extrusion food industry.

Now our extrusion equipment has been applied in snack foods, professional cereal products, leisure foods, pet dog cat foods, instant noodles etc.

“Aim for the sake of customers, for the customer value-added” is the tenet of our company. Now our customers are around South Eastern Asia, Asia,Europe, America, South-America, Africa, and South-Africa. We sincerely hope that we may have a chance to cooperate with each other in the near future.

Our wonderful service ( corn flakes extruding machine )

Pre-sale service

1. Related machines’s technical parameter will be supplied to

customer.

2. According to customer’s factory size, factory layout can be

provided in advance.

3. According to customer’s material cost, general formulation

can be prepared well.

4. Special machine can be supplied as customer’s request.

5. Professional Advice about Market, machines, processing ,

materials, packing

can be supplied

6. Suggesting professional ship agent or helping book ship as

customer request.

After sale service:

1.

Allocation chart as the buyer’s request will be supplied.

2.

Operation manual will be supplied after shipment.

3.

One year warrantee, life time maintenance with cost price.

4.

Free easy broken spare parts will be sent with container .

5.

First installation can be done by engineer.

6. Training workers in customer’s factory